As the auto industry rapidly evolves, automotive repair schools face new challenges. Today’s vehicles are packed with complex electronics, hybrid systems, and cutting-edge safety features. To prepare students for this new reality, schools need advanced training equipment for automotive that goes beyond traditional tools.

In this article, we’ll explore why investing in modern training systems matters, what equipment is essential, and how Richter’s comprehensive portfolio fits perfectly into automotive education today. Whether you run a training center or manage a vocational program, this guide will help you understand how to boost teaching effectiveness and graduate highly capable technicians.

Table of Contents

Why Modern Training Equipment For automotive Is a Must

Vehicles today aren’t just mechanical—they’re computers on wheels. From CAN-BUS networks and electronic control units (ECUs) to electric motors and battery management systems, technicians must grasp diverse systems. Training schools without up-to-date equipment risk graduating students unprepared for real-world diagnostics and repairs.

Here’s what advanced training equipment for automotive offers:

- Realistic Hands-On Experience: Students engage with OEM-grade parts and modules, not just simplified models. This realism builds practical confidence.

- Safety and Compliance: Modern trainers simulate high-voltage and hydraulic systems safely, reducing injury risk during learning.

- Fault Injection & Simulation: Instructors can program faults into systems, training students on troubleshooting and repair without damaging real vehicles.

- Integration with Software: Virtual diagnostic tools paired with hardware create a blended learning experience, mirroring real service bays.

- Adaptability to EV and Hybrid Systems: As electric vehicles grow in market share, schools must train on battery packs, drive motors, and power electronics.

Richter’s equipment ticks all these boxes and more, providing your school with a future-proof solution.

Core Equipment Types Every Repair School Needs

| Equipment Category | Key Features & Benefits | Richter Product Examples |

|---|---|---|

| Engine Trainers | Assembly/disassembly, combustion & cooling systems | Gasoline Engine Disassembly and Assembly Trainer |

| Electrical System Trainers | CAN-BUS simulation, air conditioning, electric seats | Automotive CAN-BUS System Training Board |

| Chassis & Brake Trainers | ABS, EBD, power steering, transmission systems | Automotive ABS Braking System Trainer |

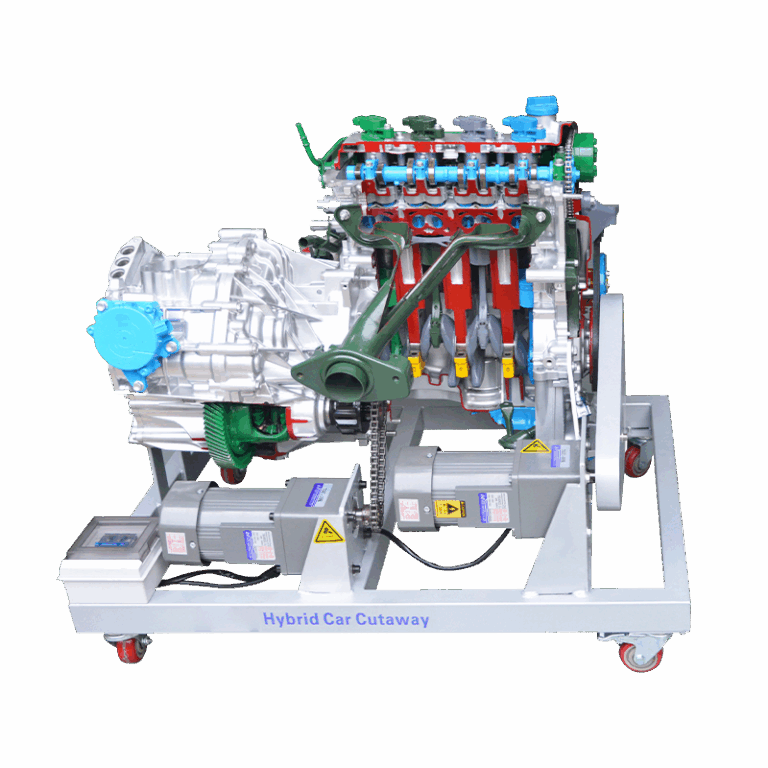

| EV & Hybrid Trainers | Battery testing, powertrain assembly, fault diagnosis | Electric Vehicle Power Chassis Fault Diagnosis Training System |

| Simulation Software | Virtual diagnostics, motor assembly, battery handling | Electric Vehicle Fault Diagnosis Training Software |

This table highlights how Richter’s extensive lineup supports broad training needs, from traditional engines to next-gen electric vehicles.

Real-Life Case: Boosting Diagnostic Skills with Fault Injection

A technical school in Europe reported major improvements in student outcomes after adopting fault injection trainers. Instead of static lessons, instructors programmed faults such as sensor failures or circuit breaks into Richter’s Automotive CAN-BUS System Training Board. Students learned to systematically identify and resolve issues, mirroring real workshop challenges.

This approach decreased troubleshooting time by 25% among graduates and reduced instructor intervention by 30%, freeing up teaching resources.

Industry Jargon You’ll Hear in Training Centers

- CAN-BUS (Controller Area Network-Bus): The communication protocol connecting ECUs. Simulated CAN-BUS helps students decode complex wiring and signals.

- ECU (Electronic Control Unit): The “brain” of many vehicle functions. Advanced trainers include ECU modules to teach diagnostics.

- BMS (Battery Management System): Critical for electric vehicles, monitoring battery health. Understanding BMS is vital as EV repair grows.

- Fault Injection: Introducing simulated faults for hands-on troubleshooting training.

- High-Voltage Safety Training: Teaches proper protocols for handling dangerous EV systems safely.

Mastering this terminology and technology is essential for students to succeed in modern auto repair careers.

How Richter Supports Schools with Turnkey Solutions

Richter isn’t just a supplier—it’s a partner in education. Here’s how Richter enhances training programs:

- Comprehensive Catalog: From engine trainers to full EV powertrains, Richter covers all critical systems.

- Customizable Training: Equipment is modular, allowing schools to scale and adapt based on curriculum needs.

- Integrated Software: Diagnostic simulation software complements physical trainers, reinforcing theory with practice.

- High Quality & Durability: Built for frequent use, reducing maintenance downtime and replacement costs.

- Global Support: Training, installation, and ongoing service ensure smooth operation.

For example, the Power Battery Assembly and Testing Technology Training System blends hands-on disassembly with diagnostic software, perfect for schools tackling EV technology.

The Business Value: Why Investing in Advanced Trainers Makes Sense

A common pain point for schools is budget constraints. However, investing in Richter’s advanced trainers delivers strong ROI:

| Challenge | Traditional Approach | Richter Solution | Benefits |

|---|---|---|---|

| Limited hands-on practice | Risk of damaging costly vehicles | Simulated fault injection and modular trainers | Reduced repair costs by 35% |

| Outdated curriculum | Graduates unprepared for EVs and hybrids | Full EV and hybrid system trainers | Higher graduate employability |

| High instructor workload | One-on-one coaching needed | Self-paced simulation software | Frees up 30% instructor time |

| Equipment maintenance | Frequent wear and tear on real parts | Durable training boards and simulators | Cuts replacement cost by 40% |

Richter trainers help you deliver better training, reduce expenses, and attract more students with cutting-edge tech.

Future Trends: VR, AI, and Remote Learning in Auto Repair Training

The future of automotive training is tech-driven. Virtual reality (VR) and artificial intelligence (AI) are emerging as powerful tools to enhance hands-on learning remotely.

While Richter currently focuses on physical and software trainers, integration with VR and AI platforms is a natural next step. This will allow schools to offer immersive, interactive training that adapts to individual student needs, even during times when in-person labs are limited.

Wrapping Up: Equip Your School for Tomorrow’s Auto Industry Today

Automotive repair schools can no longer rely on outdated equipment. To prepare students for modern vehicles, investing in advanced training equipment for automotive is essential. Richter provides a broad, high-quality selection of trainers and software designed to meet evolving educational demands—from gasoline engines to electric vehicles.

By embracing Richter’s solutions, schools:

- Deliver realistic, safe, and engaging training

- Build confident, skilled graduates ready for the job market

- Reduce costs through durable equipment and simulation

- Stay ahead of industry trends with adaptable technology

Invest wisely today, and empower your students to become the skilled auto technicians of tomorrow.