Electric vehicles (EVs) are no longer just a futuristic concept. They’re on our roads, in our cities, and changing the face of transportation. As this shift gains speed, schools have a critical role to play in preparing the next generation of automotive professionals. One of the key tools for this preparation? Electric vehicle battery testing equipment.

If you’re an educator or training institution, you might wonder: Why invest in specialized EV battery testing gear? How does it help students? What kind of equipment really makes a difference in hands-on learning? This article breaks down these questions, highlights real scenarios, and shows how Richter’s automotive training solutions fit into the picture.

Table of Contents

Why Schools Need EV Battery Testing Equipment

1. Bridging Theory and Practice in Real-World EV Technology

It’s one thing to read about lithium-ion battery chemistry or battery management systems (BMS) in textbooks. It’s another to handle a battery pack, measure voltage, test charge cycles, or diagnose faults firsthand. EV battery testing equipment brings these concepts off the page and into the lab.

For example, many schools struggle to give students real exposure to EV systems because high-voltage batteries are complex and potentially dangerous without the right setup. With dedicated test trainers and simulators, students get to safely explore battery pack construction, charging/discharging behavior, and performance under load.

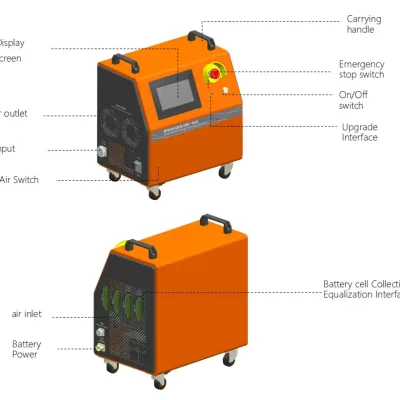

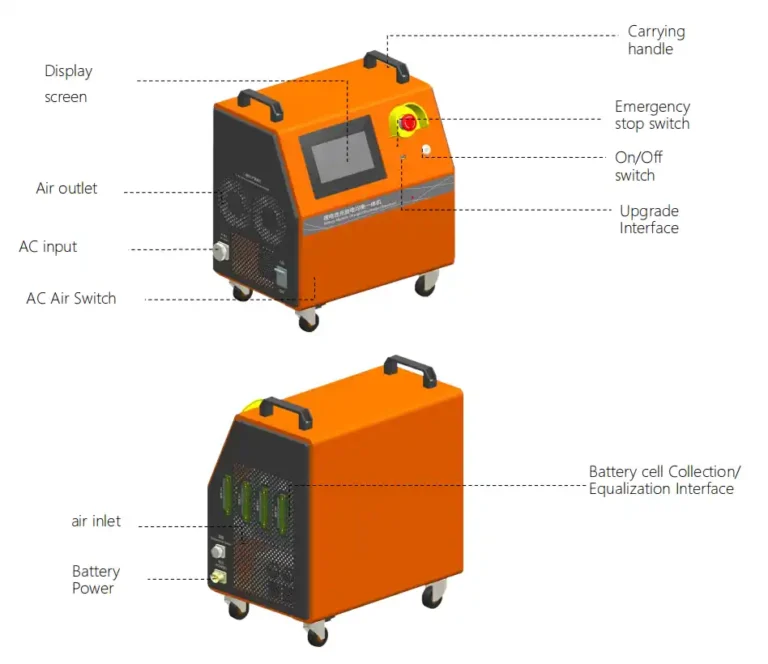

Richter offers Power Battery Assembly and Testing Technology Training Systems that precisely address this challenge. These systems replicate the real battery pack environment but with safety and modularity, allowing students to build, test, and analyze cells and modules without risks.

2. Enhancing STEM Education with Hands-On Learning

Science, Technology, Engineering, and Mathematics (STEM) education is at the heart of modern training. EV battery testing gear adds a layer of project-based learning that brings STEM concepts to life.

Take a practical classroom project: Students build a model EV battery pack, run charging/discharging cycles, measure internal resistance, and analyze capacity fade. This hands-on approach deepens understanding far better than lectures alone.

Moreover, these systems allow for cross-disciplinary learning. Students combine electrical engineering knowledge with chemistry, safety protocols, and even data analysis skills by logging test results.

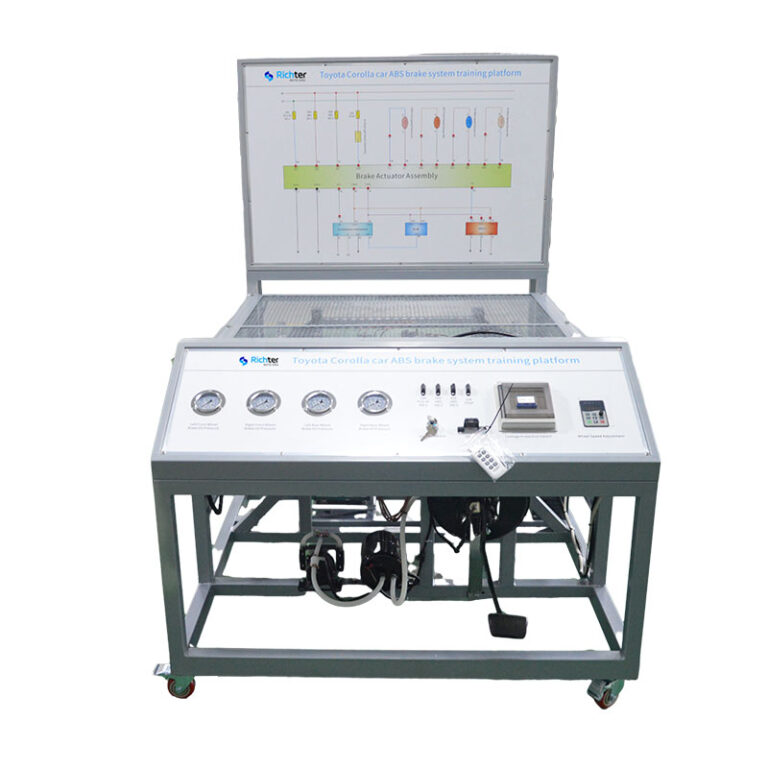

At Richter, products like the Electric Vehicle Power Chassis Fault Diagnosis Training System support these integrated learning scenarios by including fault injection and troubleshooting exercises.

3. Preparing Students for the Green Economy and Sustainability Challenges

The shift to electric mobility is a major pillar in reducing carbon emissions and fostering sustainability. Schools have the chance—and responsibility—to educate students on these green technologies.

Battery testing equipment can also be used to explore battery recycling, second-life applications, and environmental impact assessments. Understanding battery degradation and reuse scenarios gives students a holistic view of EV sustainability.

Real-world data shows that lithium-ion batteries typically last 8–15 years in vehicles before capacity drops. Testing equipment helps simulate these aging processes, teaching students why and how batteries degrade. This knowledge is essential for careers in EV maintenance, recycling, or energy storage sectors.

4. Providing Safe, Modular, and Scalable Training Solutions

Safety is non-negotiable when working with EV batteries. High voltages, thermal risks, and chemical hazards make unregulated practice risky. Fortunately, modern testing equipment comes with built-in protections.

Richter’s training systems include features like overvoltage and overcurrent protection, insulated connectors, and emergency cut-offs to prevent accidents during hands-on labs.

Modularity is another big plus. Schools can start with a basic battery pack test trainer, then upgrade or expand as budgets and courses grow. This flexibility ensures long-term value.

Key Features of EV Battery Testing Equipment for Schools

| Feature | Why It Matters | Example from Richter Products |

|---|---|---|

| High Voltage Safety Controls | Protects users from electric shocks and fire hazards | Power Battery Assembly and Testing System includes emergency stop and insulation monitoring. |

| Battery Pack Assembly Simulation | Helps students understand real pack wiring and design | Training board models battery modules and cell interconnections. |

| Charge/Discharge Cycle Testing | Teaches battery performance, capacity, and aging | Allows multiple cycles, mimicking real driving conditions. |

| Data Logging and Analysis | Enables detailed evaluation and troubleshooting | Software captures voltage, current, temperature trends for study. |

| Fault Injection & Diagnosis | Builds troubleshooting skills by simulating failures | Fault diagnosis trainers introduce real faults for hands-on repair. |

| Modular Design | Scales with curriculum and budget | Systems can be expanded from basic packs to full EV powertrains. |

| User-Friendly Interface | Makes complex tech approachable for students | Interactive control panels and PC interfaces simplify use. |

Real Cases of Schools Using EV Battery Testing Equipment

Case 1: A Vocational College in Germany

A vocational school in Germany incorporated a Power Battery Assembly and Testing Technology Training System into its curriculum. Before introducing this equipment, students learned mostly theory. Afterward, practical lab hours increased by 40%, and student engagement rose significantly.

The school reported graduates felt more confident entering EV maintenance roles, reducing onboarding time at partner automotive companies by 30%. This example highlights how hands-on testing gear can boost both learning outcomes and employment readiness.

Case 2: Technical University in the U.S.

A technical university in the U.S. integrated battery testing trainers alongside software simulators. Their EV course combined physical battery pack assembly with simulation of charge/discharge cycles and fault diagnostics.

This dual approach helped students grasp both hardware and software sides of EV batteries. Graduates from this program have secured internships at major EV manufacturers and battery startups.

Richter’s Electric Vehicle Fault Diagnosis Training Software for Automotive Education supports these blended learning experiences perfectly.

Common Pain Points in EV Battery Training — And How Richter Solves Them

| Pain Point | Explanation | Richter Solution |

|---|---|---|

| High Initial Equipment Cost | EV battery trainers can be expensive, limiting budgets | Modular systems allow schools to start small and expand gradually. |

| Safety Concerns | Handling high-voltage batteries is risky | Built-in protections and training protocols reduce hazards. |

| Complex Technology Barrier | Students may find EV batteries complicated | User-friendly interfaces and step-by-step guidance simplify learning. |

| Lack of Realistic Testing Scenarios | Theory doesn’t match real EV system behavior | Fault injection and cycle testing replicate actual field conditions. |

| Difficulty Integrating into Curriculum | Schools unsure how to blend training with theory | Comprehensive teaching materials and software make integration easier. |

How Richter’s Products Fit into Your School’s EV Training Program

Richter understands the unique challenges training institutions face. With decades of experience supplying automotive education equipment worldwide, Richter designs EV battery testing systems focused on safety, scalability, and realism.

- Safety First: Every product has multiple built-in safety layers, from insulation monitoring to emergency shutdowns. You won’t have to worry about risking student wellbeing during experiments.

- Flexible & Modular: Start with a basic battery testing trainer. Later add powertrain modules or advanced fault simulation systems as your course evolves.

- Integrated Software: Richter’s training software syncs with hardware to log real-time data, enabling instructors and students to analyze battery health, performance, and failures in detail.

- Industry-Relevant: Our equipment models the latest EV battery technologies, so your students gain skills they’ll use in real workshops and factories.

Concrete Cost Savings and ROI for Schools

Many educators hesitate because they see EV battery trainers as a costly investment. But consider these real numbers:

- A standard EV battery trainer system costs between $10,000 and $50,000 depending on features.

- By improving hands-on learning, schools report a 25-40% reduction in student repeat rates for practical exams.

- Partnering with local EV repair shops or manufacturers, schools often secure internship agreements, increasing student placement rates by up to 35%.

- Faster student onboarding means partner companies save thousands annually in training costs—making your school a preferred talent source.

In short, investing in quality EV battery testing equipment creates a positive ripple effect: better student outcomes, stronger industry ties, and enhanced institutional reputation.

Final Thoughts: The Future of EV Training Starts in Schools

The global shift to electric vehicles is only accelerating. Schools that act now to equip students with practical EV battery testing skills will shape the workforce of tomorrow.

Richter’s range of training systems offers safe, scalable, and industry-aligned solutions that bridge the gap between classroom and garage. With these tools, your students can gain confidence, competence, and a competitive edge.

If you’re ready to bring hands-on EV battery training to your institution, check out Richter’s offerings today and take the first step toward empowering the next generation of EV technicians.