Automotive education equipment for diesel engines still power a huge part of the automotive world—from trucks and buses to marine and industrial machinery. Training skilled diesel technicians requires more than textbooks; it demands hands-on education equipment that reflects the complexity and evolution of modern diesel systems.

In this article, we’ll explore why advanced diesel education equipment matters, how it’s used in training, and how Richter’s range of trainers and tools offers practical solutions for automotive schools and workshops alike.

Table of Contents

Why Diesel Engine Training Equipment Is Essential Today

Automotive ducation equipment for diesel engines have come a long way. Modern common rail systems, electronic controls, turbochargers, and emission controls require specialized knowledge. Here’s why hands-on diesel trainers are indispensable:

- Bridging Theory and Practice: Students learn complex mechanical and electronic diesel systems with real parts.

- Safe Fault Simulation: Trainers enable fault injection so learners can diagnose and fix issues without risking costly equipment.

- Complying with Emission and Safety Standards: Newer diesel tech demands understanding of emission regulations and safety protocols.

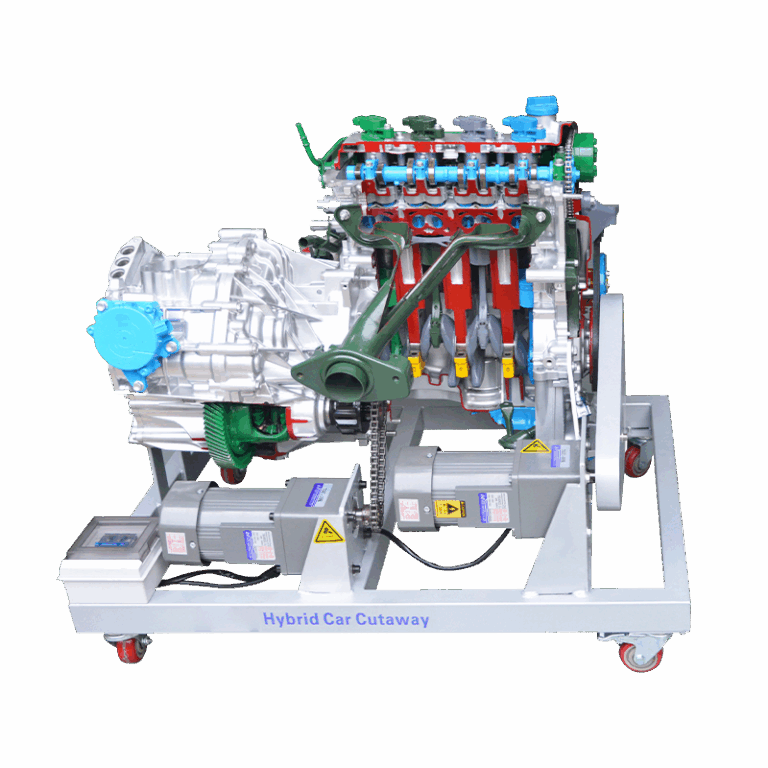

- Preparing for Hybrid Diesel & Electric Systems: Diesel tech now often integrates with electric components, requiring cross-disciplinary training.

Richter’s automotive education equipment for diesel engines cover all these needs and prepare students for a wide range of repair scenarios.

Main Types of Diesel Engine Education Equipment

| Equipment Type | Training Focus | Richter Examples & Links |

|---|---|---|

| Diesel Engine Disassembly & Assembly | Mechanical components, turbochargers, fuel injection | Diesel Engine Disassembly and Assembly Trainer |

| Common Rail Electric Control Trainers | Electronic control units, fuel rail pressure regulation | Diesel Common Rail Engine Electric Control System Training Board |

| Diesel Engine Complete Trainers | Full system diagnostics, mechanical & electronic integration | Diesel Engine Trainers |

| Diesel Engine with Manual Transmission Trainers | Transmission systems, clutch and gearbox diagnosis | Diesel Engine with Manual Transmission Trainers |

Real-World Training Example: Diesel Common Rail Diagnostics

A technical school in Germany adopted Richter’s Diesel Common Rail Engine Electric Control System Training Board. Instructors used fault injection modes to simulate sensor errors and injector failures. Students quickly gained confidence interpreting ECU signals and applying diagnostic procedures.

This hands-on approach cut student troubleshooting times by 30% compared to traditional theory-heavy teaching. Graduates reported feeling better prepared for modern diesel repair jobs.

Industry Terms You’ll Hear in Diesel Training

- Common Rail: High-pressure fuel injection system improving efficiency and emissions.

- ECU (Engine Control Unit): The computer managing fuel delivery, turbo boost, and emissions.

- Turbocharger: Boosts engine power; requires understanding of air intake and exhaust flows.

- Emission Control Systems: Components like EGR (Exhaust Gas Recirculation) and DPF (Diesel Particulate Filter) essential for compliance.

- Fault Injection: Simulating engine faults for realistic diagnostic practice.

Mastering these terms and components is key to skilled diesel maintenance.

Why Richter Is Your Go-To Diesel Training Partner

Richter offers more than just equipment—they deliver comprehensive learning systems:

- Durable and Realistic: Trainers replicate OEM systems accurately, built for educational use.

- Modular and Scalable: Mix trainers to cover mechanical, electronic, and transmission systems.

- Integrated Diagnostics: Software tools complement physical trainers, deepening understanding.

- Safety-First Design: Trainers include safety protocols critical for diesel engine handling.

- Global Support: Installation, training, and maintenance ensure smooth program operation.

Business Impact: Investing in Diesel Training Equipment Pays Off

| Training Challenge | Traditional Method | Richter Solution | Benefits |

|---|---|---|---|

| Lack of practical exposure | Theory-heavy classes | Hands-on trainers with fault simulation | Better prepared graduates |

| High repair costs | Trial-and-error diagnostics | Realistic diagnostics and safe fault practice | Reduced costly errors |

| Compliance struggles | Limited emission control knowledge | Emission system trainers included | Easier regulatory compliance |

| Technician retention | Low skill confidence | Comprehensive, interactive learning | Higher retention and job satisfaction |

Looking Ahead: Hybrid Diesel and Electric Training

With the rise of hybrid diesel vehicles, auto edu training must be evolved. Richter is developing trainers that integrate electric drive components with diesel powertrains, preparing students for the future of diesel tech.

Conclusion: Equip Your School for Diesel Excellence

Diesel engines are still a massive part of the automotive industry, but repairing them requires up-to-date, hands-on training. Richter’s automotive education equipment for diesel engines delivers realistic, safe, and comprehensive automotive training.

Ready to equip your school with the best?