Running a repair workshop today isn’t what it used to be. With cars packed full of electronics, hybrids, and electric drivetrains, your technicians need training systems that match this complexity. That’s why advanced automotive training systems have become essential—not just for schools, but for repair workshops aiming to stay competitive.

This article dives into why modern training tools matter, what types of systems you should invest in, and how Richter’s comprehensive equipment lineup can transform your workshop training. If you want skilled techs who fix problems fast and safely, keep reading.

Table of Contents

Why Invest in Automotive Training Systems for Workshops?

The automotive repair landscape has shifted. Technicians face challenges like:

- Diagnosing CAN-BUS communication errors

- Handling high-voltage electric and hybrid components

- Troubleshooting computerized engine and transmission controls

- Maintaining safety around complex hydraulic and pneumatic systems

Without proper hands-on training tools, these challenges can cause costly mistakes and slow repairs.

Investing in automotive training systems offers:

- Realistic Practice: Trainees work on actual parts and systems, not just textbooks or guesswork.

- Fault Simulation: Training systems allow deliberate introduction of faults, preparing techs for real-life scenarios.

- Safety Protocols: Teaching safe handling of high-voltage and pressurized systems reduces accidents.

- Efficiency Gains: Better-trained techs diagnose and repair faster, boosting customer satisfaction.

Core Automotive Training Systems for Modern Workshops

| Training System Type | Key Features & Benefits | Richter Product Examples & Links |

|---|---|---|

| Engine Trainers | Engine assembly/disassembly, lubrication, cooling | Gasoline Engine Disassembly and Assembly Trainer |

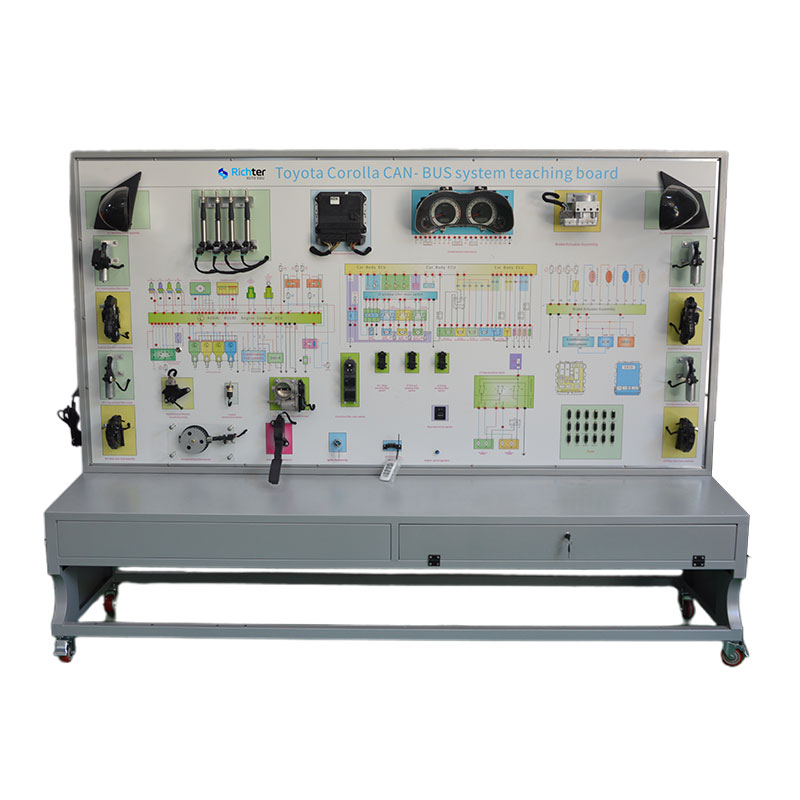

| Electrical System Trainers | CAN-BUS diagnostics, electric seats, HVAC | Automotive CAN-BUS System Training Board |

| Chassis & Brake Trainers | ABS, EBD, power steering, transmission | Automotive ABS Braking System Trainer |

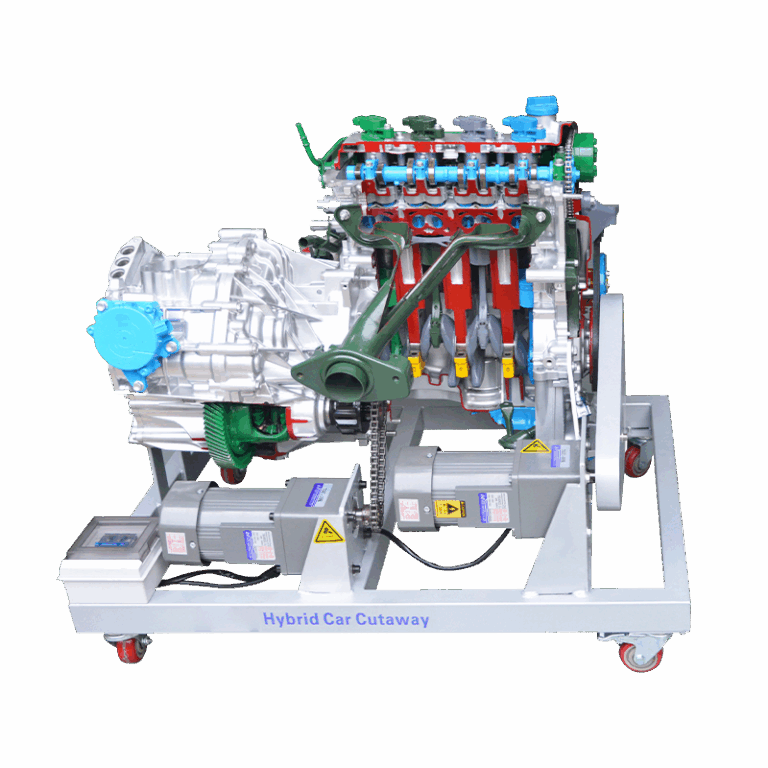

| EV & Hybrid Trainers | Battery testing, drive motor diagnosis, HV safety | Electric Vehicle Power Chassis Fault Diagnosis Training System |

| Simulation Software | Virtual diagnostics, motor and battery assembly | Electric Vehicle Fault Diagnosis Training Software |

Richter covers all these bases, letting your workshop build versatile technicians ready for every vehicle that rolls in.

Case Study: Reducing Diagnostic Time with Richter’s Automotive Training Systems

A busy repair shop in Germany integrated Richter’s Automotive CAN-BUS System Training Board and Electric Vehicle Power Chassis Fault Diagnosis Training System into its ongoing technician training. Within six months, their average diagnostic time dropped by 20%, thanks to more confident, hands-on skills.

Their lead tech said, “Fault injection on these trainers lets our team experience real-world CAN errors and electric drivetrain issues before they hit the customer cars. It’s cut down trial and error hugely.”

Industry Jargon Decoded: What Workshop Techs Should Know

- CAN-BUS: Communication protocol linking car modules; mastering CAN diagnostics is critical.

- EBD (Electronic Brakeforce Distribution): A system that balances braking power, vital for safety checks.

- High Voltage (HV) Safety: Proper protocols for EV/hybrid battery handling; training systems simulate this.

- Fault Injection: Purposeful fault introduction for diagnostic practice.

- Powertrain Diagnostics: Understanding engine and transmission controls through simulators.

Training your team on these will improve their troubleshooting and repair accuracy.

Business Benefits of Using Richter Auto Training Systems in Workshops

| Problem | Traditional Approach | Richter Training Solution | Benefits |

|---|---|---|---|

| Long diagnostic times | Learning on-the-job mistakes | Fault simulation and hands-on training | 20-30% faster diagnostics |

| Safety incidents | Risk of HV shock or injury | Simulated HV safety trainers | Reduced accidents and liability |

| Technician turnover | Low confidence, poor skill growth | Continuous skill upgrading with modular tools | Better retention, higher morale |

| Repair errors | Trial-and-error repairs | Systematic fault diagnosis practice | Fewer comebacks and warranty claims |

Richter’s durable and comprehensive training tools give your shop a strong competitive edge.

The Future: Remote Learning & AI-Enabled Training Systems

Workshops adopting remote diagnostics and AI-enhanced training are seeing huge advantages. Richter is exploring ways to integrate these innovations with their hands-on trainers to provide hybrid learning models—helping technicians stay sharp even when they can’t be onsite.

Final Thoughts: Build a Workshop Team Ready for Today and Tomorrow

To stay competitive in a fast-changing auto industry, repair workshops must train technicians on advanced systems. Richter’s automotive training systems are designed to make learning realistic, safe, and efficient.

Explore Richter’s lineup for your workshop and start building tech expertise that keeps pace with evolving vehicle technologies.