The EV revolution isn’t coming; it’s here. But beneath the glossy showrooms and silent acceleration lies a dirty little secret threatening to stall the whole transition – a critical shortage of technicians who truly understand how to keep those expensive, complex battery packs alive and safe. Forget oil changes; the future of auto repair lives and dies with the battery. And the bridge between theoretical knowledge and hands-on, shop-floor competence? Specialized electric vehicle battery maintenance training equipment. This isn’t just nice-to-have; it’s the industry’s defibrillator.

Table of Contents

The Battery Skills Gap: A Ticking Time Bomb

The numbers don’t lie. McKinsey predicts the global EV market will balloon to a staggering $1.3 trillion by 2030. Meanwhile, the International Energy Agency (IEA) reports EV sales surged past 10 million units in 2022 alone. But here’s the kicker: a 2023 study by TechForce Foundation highlighted a 30% increase in demand for EV-specific technicians year-over-year, while qualified supply remains painfully thin. Dealerships and independent shops are scrambling. Why?

- High Voltage = High Stakes: Messing with a 400V or 800V battery pack isn’t like swapping a lead-acid battery. One wrong move can mean catastrophic failure, thermal runaway (think unstoppable fire), or fatal electrocution. Technicians need muscle memory for safety protocols that only rigorous, hands-on practice provides. You can’t YouTube your way out of a high-voltage fault.

- BMS Black Magic: The Battery Management System (BMS) is the pack’s brain. Diagnosing issues here – cell balancing failures, state-of-charge (SOC) drift, communication errors – requires deep understanding beyond basic OBD-II scans. It’s interpreting complex data streams and understanding the interplay between hardware and software. Classroom theory falls flat here.

- The Cost of Ignorance is Astronomical: A botched repair on a battery module can brick an entire pack. Replacement costs? Think

15,000 to30,000+ for many models. That’s a total loss for many vehicles and a massive warranty hit for OEMs. Proper maintenance and accurate diagnosis are existential for cost control. - Rapid Obsolescence: Battery tech evolves faster than smartphone designs. LFP, NMC, solid-state whispers – technicians need adaptable training platforms that can keep pace, not static textbooks.

Enter the Trainers: From “Book Smart” to “Shop Floor Ready”

This is where purpose-built electric vehicle battery maintenance training equipment becomes non-negotiable. It transforms abstract concepts into tangible skills. Let’s break down the essential kit:

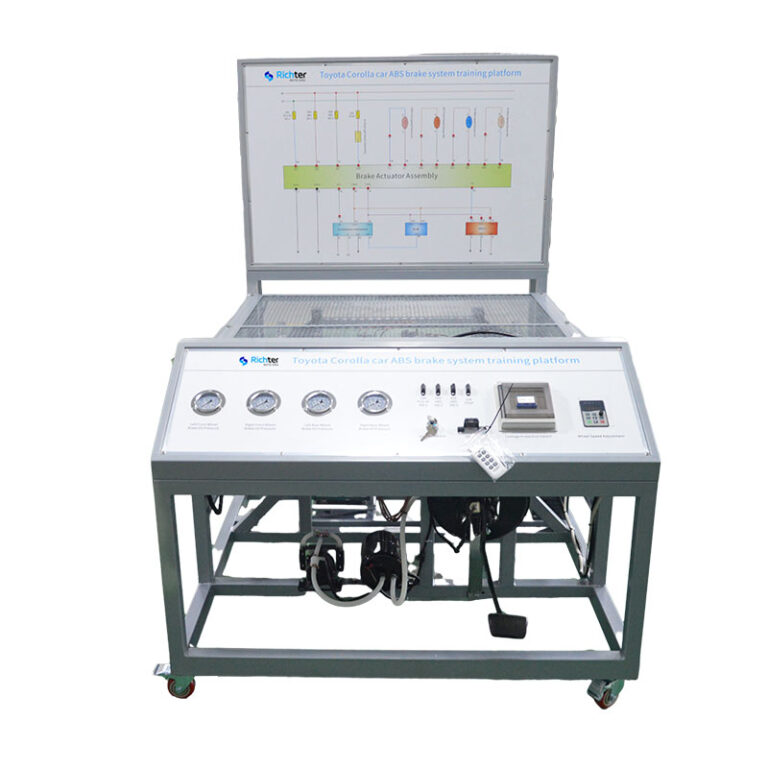

- The Physical Dissection & Assembly Bench (The “Pack Teardown” Station):

- The Pain Point: Understanding pack architecture is foundational. How do modules connect? Where are the contactors? What does a coolant loop actually look like inside? Schematics only go so far.

- The Solution: Trainers like Richter’s Power Battery Assembly and Testing Technology Training System use actual, de-energized battery modules and packs mounted on robust workstations. Trainees physically disassemble and reassemble packs, trace coolant paths, identify sensors, and practice safe high-voltage connector handling (think orange cables, safety interlocks). This builds spatial awareness and procedural confidence impossible to gain otherwise. See it in action: Power Battery Assembly and Testing Technology Training System

- The “Aha!” Moment: When a trainee feels the torque required on a module busbar connector or sees the intricate layout of the thermal management plates, theory clicks into place.

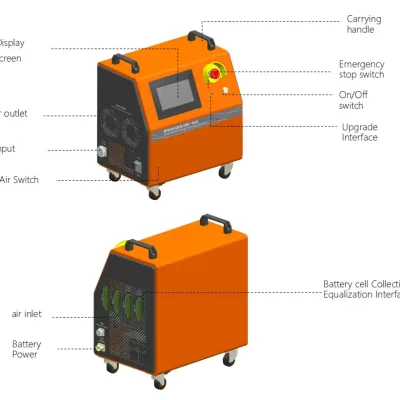

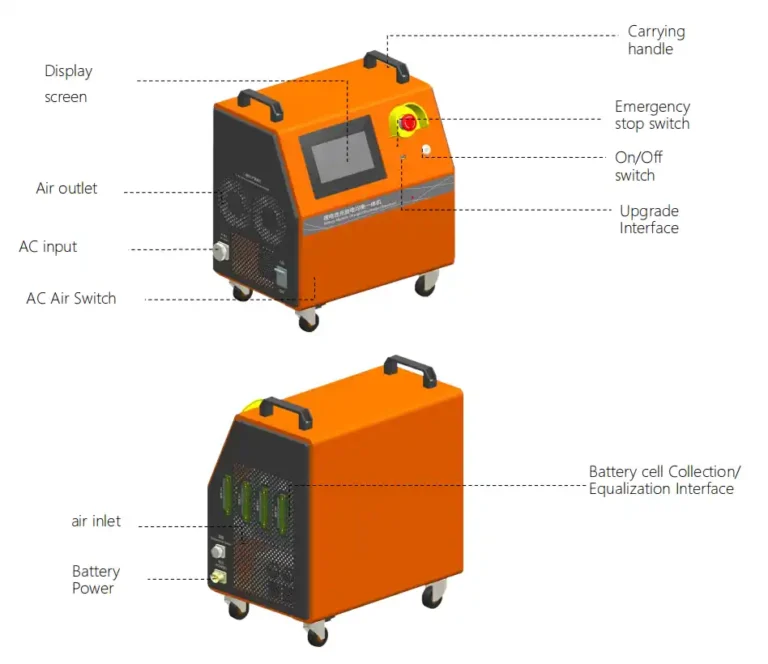

- Fault Injection & Diagnostic Trainers (The “Controlled Chaos” Simulator):

- The Pain Point: Real-world battery faults are messy. How do you safely simulate a failing cell voltage sensor, a stuck contactor, or a BMS communication breakdown? You can’t just break a customer’s $100k car.

- The Solution: Advanced trainers like Richter’s Electric Vehicle Power Chassis Fault Diagnosis Training System integrate real battery components with sophisticated electronics that allow instructors to intentionally induce dozens of common (and uncommon) faults. Trainees then use real scan tools, multimeters, and oscilloscopes to diagnose the problem, following OEM-level diagnostic procedures. Color-coded wiring harnesses mimic real vehicle layouts. Explore this system: Electric Vehicle Power Chassis Fault Diagnosis Training System

- The “Black Box” Unlocked: Trainees learn to interpret BMS data logs, pinpoint communication errors on CAN buses, differentiate between sensor failures and actual cell degradation, and validate repairs – all in a safe, repeatable environment. This is where diagnostic intuition is forged.

- HV Component Specific Trainers (The “Controller Deep Dive”):

- The Pain Point: Key components like the Battery Disconnect Unit (BDU), onboard charger (OBC), DC-DC converter, and the main traction inverter are critical yet complex. Understanding their operation, testing procedures, and safe handling is paramount.

- The Solution: Dedicated trainers isolate these components. Take Richter’s Electric Vehicle Original High-voltage Control Box Assembly Disassembly and Testing System. It uses real OEM HV control boxes (often salvaged from end-of-life vehicles). Trainees learn safe disassembly/reassembly sequences, identify internal components (contactors, fuses, current sensors), practice functional testing using manufacturer protocols, and understand failure modes. Dive into component training: Electric Vehicle Original High-voltage Control Box Assembly Disassembly and Testing System

- Beyond the Surface: Moving beyond “replace the whole unit” to understanding which internal component failed (e.g., a welded contactor vs. a blown pyro fuse) saves massive costs and diagnostic time.

- Simulation & Virtual Reality (VR) Software (The “Zero-Risk” Sandbox):

- The Pain Point: Some procedures are too risky or complex for initial hands-on training. Visualizing internal BMS logic or practicing rare fault scenarios needs a safe space.

- The Solution: Software like Richter’s Electric Vehicle Fault Diagnosis Training Software creates immersive virtual environments. Trainees can “disassemble” a virtual battery pack layer by layer, run simulated diagnostic routines, see the impact of different faults on BMS data in real-time, and practice safety procedures endlessly without risk. Experience virtual training: Electric Vehicle Fault Diagnosis Training Software

- The Scalability Factor: VR/Sim software allows institutions to train more students concurrently on complex concepts before they touch expensive physical hardware, maximizing resource utilization.

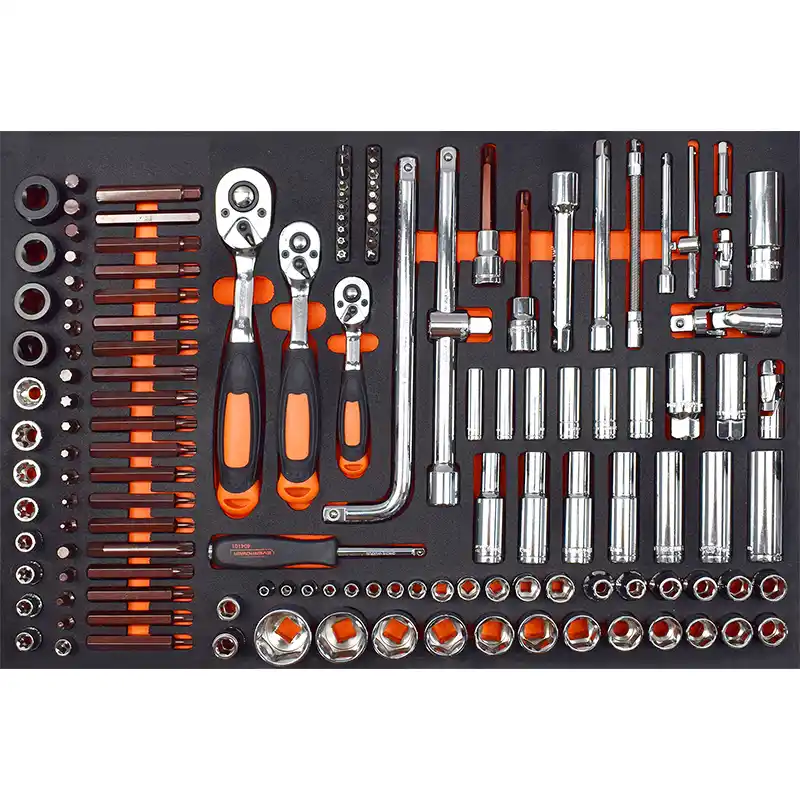

- Specialized Tools & Instrumentation (The “Insulated Arsenal”):

- The Pain Point: Standard auto tools are death traps around HV systems. Technicians need CAT III/CAT IV 1000V+ rated multimeters, insulated socket sets, HV gloves with regular testing, battery insulators, and dedicated pack diagnostic tools.

- The Solution: Training programs must incorporate and mandate the use of proper HV tools. Kits like Richter’s 318 Electric Automotive (Insulated) Hybrid Tool Car Set provide the essential, certified toolkit trainees need to practice safely, building the habit of using the right tool for the HV job from day one. Equip your trainees: 318 Electric Automotive (Insulated) Hybrid Tool Car Set

- Muscle Memory for Safety: Handling insulated tools becomes second nature, reducing complacency risks in the real workshop.

The Richter Edge: Bridging the Gap with Real-World Rigor

Richter doesn’t just sell trainers; it sells operational readiness. What sets its approach apart in the EV battery training space?

- OEM DNA in Training: Trainers aren’t generic mock-ups. They integrate actual battery modules, BMS units, and HV components sourced from end-of-life EVs or manufactured to precise OEM specs. Trainees interact with the same parts and connectors they’ll see in the shop. This eliminates the “training-to-real-world” transition gap. See their practical philosophy: Richter Automotive Training Equipment

- Fault Library Breadth: Richter’s fault injection systems go beyond the basics. Simulating complex cascading failures, intermittent communication glitches, or sensor drift scenarios prepares technicians for the messy reality they’ll face, not just textbook cases.

- Emphasis on Safety Culture: Safety isn’t a module; it’s woven into every interaction with Richter trainers. From the physical design (safety interlocks, clear HV markings, discharge systems) to the curriculum, building an ingrained safety-first mindset is paramount.

- Software Integration: Recognizing that modern battery diagnostics is data-driven, Richter seamlessly blends physical hardware training with software simulation. Trainees learn to correlate what they see on the scan tool with what’s happening inside the virtual or physical pack.

- Future-Proofing Focus: The modular design of many Richter systems allows for updates. As new battery chemistries (like LFP gaining massive traction) or architectures (800V systems) emerge, training platforms can be adapted, protecting institutional investment. Explore their adaptable approach: Electric Vehicle and Hybrid Trainers

The ROI: More Than Just Avoiding Crises

Investing in high-quality EV battery maintenance training equipment isn’t an expense; it’s a strategic imperative with clear, quantifiable returns:

- Slashing Warranty Costs: Accurate first-time diagnosis and repair prevent comebacks and catastrophic, warranty-voiding mistakes on battery packs. This directly protects the bottom line for dealers and repair networks.

- Boosting Shop Throughput & Revenue: Technicians trained on advanced simulators and fault trainers diagnose complex battery issues significantly faster than those relying only on manuals or basic training. Faster turnarounds mean more jobs completed. Specialized EV battery service also commands premium labor rates.

- Attracting & Retaining Talent: Top techs want to work with cutting-edge technology and know their skills are future-proof. Offering advanced EV battery training is a powerful recruitment and retention tool in a tight labor market. It signals a shop’s commitment to the future.

- Mitigating Liability: Proper training documented through programs using certified equipment is a strong defense against liability claims arising from battery-related incidents or improper repairs. It demonstrates due diligence.

- Building Consumer Trust: As “range anxiety” gives way to “repair anxiety,” shops that demonstrably possess certified expertise in EV battery maintenance will win customer loyalty and repeat business. Trust is the new currency.

Case in Point: The Real-World Imperative

While specific public case studies involving Richter are proprietary, the industry pattern is undeniable. Consider the ripple effects of GM’s massive Chevrolet Bolt EV battery recall (costing nearly $2 billion). A significant factor in the scale and cost was the initial complexity of diagnosis and the shortage of technicians deeply trained on the specific LG Chem battery packs and procedures. Shops equipped with advanced battery trainers capable of simulating the precise cell defect and guiding safe pack handling procedures were undeniably better positioned to manage the recall efficiently and safely. This event was a wake-up call for the entire sector on the cost of not having properly trained technicians and the equipment to train them.

The Road Ahead: Solid State, Second Life, and Continuous Learning

The battery landscape isn’t static. Training equipment must evolve:

- Solid-State Batteries: Promising higher energy density and safety, these will bring new chemistries, manufacturing methods, and potential failure modes. Trainers will need to adapt to new module designs and diagnostic approaches.

- Battery Second Life & Recycling: As packs degrade below automotive use, a massive market for repurposing (stationary storage) and recycling is emerging. Training will expand to include pack grading, disassembly for recycling, and remanufacturing protocols. Equipment simulating degraded pack behaviors will be crucial.

- AI-Driven Diagnostics: BMS data combined with AI will predict failures before they happen. Training will need to incorporate interpreting AI recommendations and understanding their basis. Simulation software will be key for generating the vast datasets needed to train these AI models and the techs using them.

- Continuous Micro-Learning: The pace of change demands ongoing upskilling. Modular training systems and easily updatable software simulations will allow for bite-sized, just-in-time training on specific new procedures or technologies.

Conclusion: The Lifeline is Here

The transition to electric mobility is unstoppable. However, its long-term success hinges on a skilled workforce capable of maintaining its most vital and vulnerable component: the battery. Electric vehicle battery maintenance training equipment is not merely an educational tool; it is the essential infrastructure for a safe, sustainable, and economically viable EV ecosystem.

Institutions and businesses that proactively invest in comprehensive, hands-on training platforms – like those developed by Richter, focusing on real-world components, rigorous safety, adaptable fault simulation, and integration with diagnostic software – are not just training technicians. They are:

- De-risking their operations from costly battery failures and liability.

- Future-proofing their workforce and service offerings.

- Capturing value in the rapidly expanding EV service market.

- Building trust with consumers navigating new technology anxieties.

- Enabling the smooth, safe, and sustainable growth of electric transportation.

The skills gap is real and widening. The tools to close it, however, are readily available. The question isn’t if to invest in advanced EV battery maintenance training equipment, but how quickly it can be deployed. The shops and schools that move fastest will own the future of automotive service. Richter provides the bridge. It’s time to cross it. Start building your EV expertise: Richter Training Courses