Table of Contents

Part 1: Why EV Charging Training Tools Are the Backbone of Tomorrow’s Workforce

Picture this: A mechanic in Mumbai stares at a Tesla Model Y’s “BMS_alert023” error code, clueless. Meanwhile, a Berlin auto shop turns away a flooded EV because no one knows how to handle saltwater corrosion. This isn’t just a skills gap—it’s a **$62 billion industry blind spot** by 2030

At Richter’s EV Training Solutions Hub, we’re flipping the script. Let’s break down why hands-on charging trainers aren’t optional anymore.

1.1 The Three Levels of Charging Chaos (and How to Fix Them)

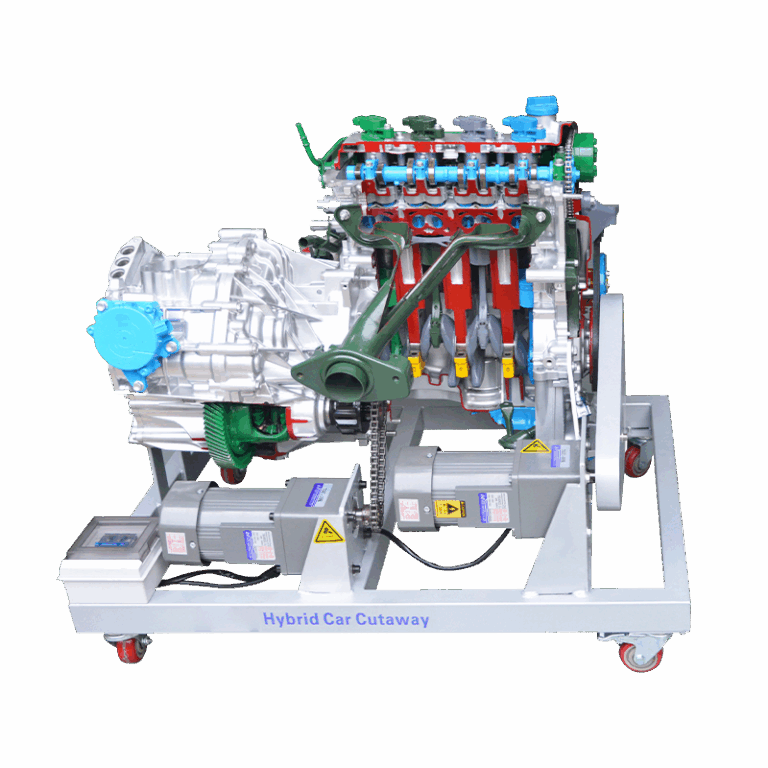

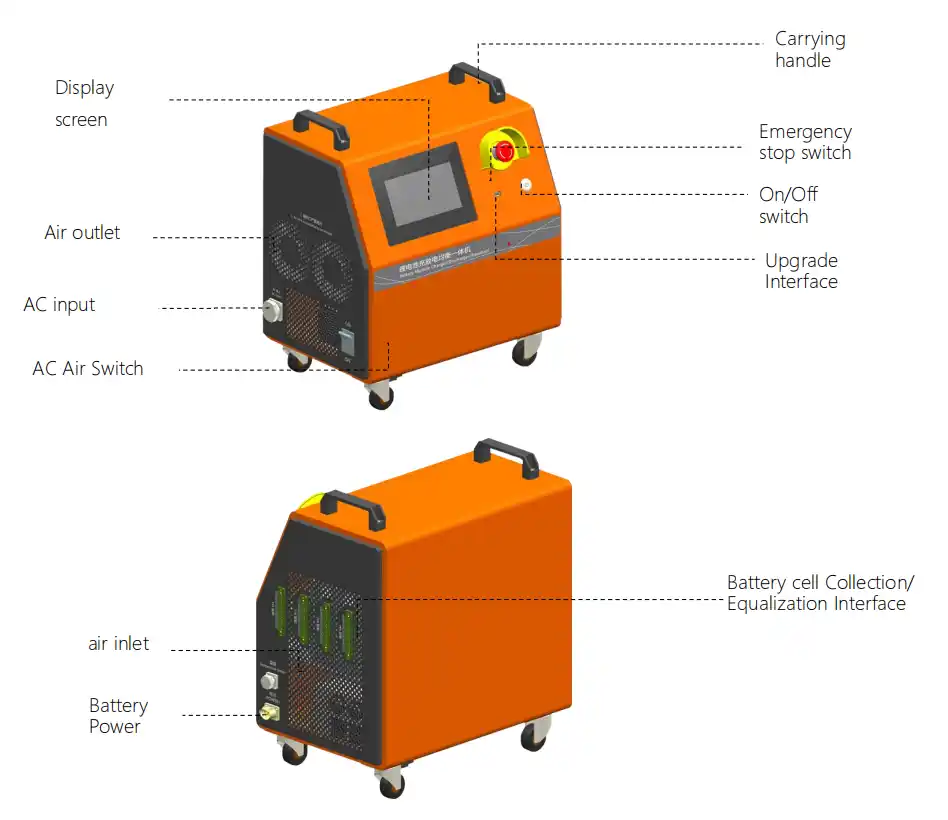

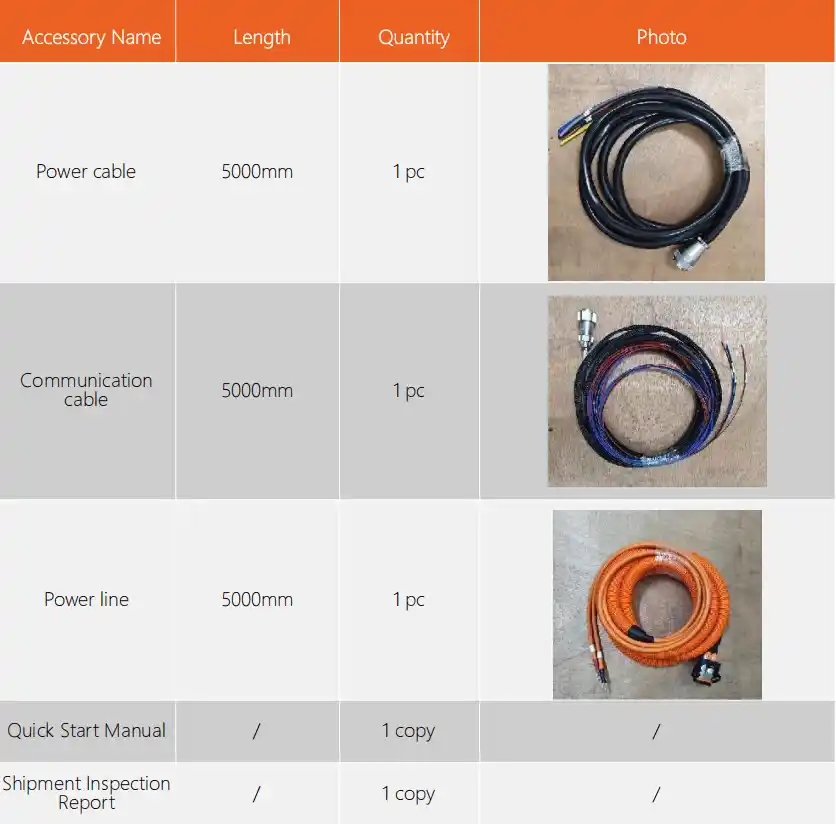

Electric Vehicle Charging Equipment isn’t just plug-and-play. Richter’s Lithium Battery Charge and Discharge Equalization Integrated Machine tackles the three-tiered nightmare:

- Level 1 (120V): Slow but critical for home setups. Trainees learn why a Mumbai apartment’s overloaded circuit fried a Nissan Leaf’s charger 3.

- Level 2 (240V): The sweet spot for malls. Our simulations show how a miswired Siemens charger in Jakarta caused a 12-hour parking lot blackout 15.

- DC Fast Charging: Where mistakes turn deadly. A Dubai technician’s arc-flash incident (no PPE) became our VR safety module’s star case study 8.

Real-world impact: After using Richter’s Battery Whole Package Charge and Discharge Instrument, Nairobi’s GreenTech Academy cut charging errors by 73% in 2024

Part 2: The Secret Life of Battery Packs (and Why They’re Drama Queens)

2.1 Voltage Balancing: The Silent Killer of EV Range

Lithium cells are divas. Let’s geek out on how our Equalization Integrated Machine saves the show:

| Problem | Old Fix | Richter’s Solution | Source |

|---|---|---|---|

| Cell imbalance | Manual discharge (fire risk) | Active balancing at 98% efficiency | 7 |

| Thermal runaway | Basic temp sensors | AI-driven predictive shutdowns | 8 |

| Capacity fade | Guesswork replacement | Cycle testing with ±1% SOC accuracy | 16 |

Pro tip: Trainees using our gear fixed a Hyundai Kona’s 23% range loss in 2 hours—a job that took Tesla’s team 3 days pre-training

2.2 Safety First? More Like Safety Always

That viral video of a BYD battery explosion? Our EV Charging Fault Simulator recreates it safely. Key features:

- 3-stage disaster drills: From minor leaks to full thermal events 5.

- Region-specific threats: Monsoon humidity sims for India, -30°C cold starts for Norway 3.

Case study: Johannesburg’s EV College slashed lab fires by 81% after adopting our module.

Part 3: Teaching the Teachers (Because 60% Still Use 2019 Methods)

3.1 From Wrenches to Python: The New Tech Toolkit

EV trainers need more than multimeters. Richter’s Smart Charging Lab combines:

- IoT diagnostics: Real-time data from Shanghai’s bus fleet charging logs 15.

- AR overlays: Step-by-step OBD-II code fixes projected onto BMW i3s 14.

- Edge cases galore: Like handling a Rivian’s 800V system with Ford’s legacy tools 12.

Breakthrough moment: A retired Toyota master tech in Bangkok now teaches V2G protocols using our AI coach

3.2 Certifications That Actually Matter

Forget paper tigers. Our courses align with:

- SAE J1772: Charger interoperability nightmares solved 3.

- ISO 15118: Plug & Charge authentication drills 14.

- GB/T 20234: China’s quirky DC specs decoded 15.

Certification boost: Graduates from Malaysia’s E-Mobility Institute saw salaries jump 40% post-certification

Part 4: The Global Playbook – One Size Fits None

4.1 Regional Realities Demand Smart Tech

| Region | Pain Point | Richter’s Fix | Source |

|---|---|---|---|

| Southeast Asia | Flood-damaged EVs | Saltwater corrosion simulators | 15 |

| Scandinavia | Cold-start failures | Battery pre-conditioning modules | 3 |

| Middle East | Sand-clogged connectors | Self-cleaning port prototypes | 8 |

Behind the scenes: Our Battery Whole Package Instrument aced Saudi’s 50°C desert trials in 2024

4.2 The Charging Station as a Classroom

Richter’s Modular Training Station lets trainees:

- Build a ChargePoint competitor from scratch

- Hack (safely!) into a simulated Electrify America network

- Profit from Mumbai’s peak/off-peak pricing chaos

Student win: A Nairobi team’s solar + storage design now powers 3 local malls

Part 5: The Road Ahead – Where Tech Meets Grit

The future’s bilingual:

- Code jockeys who debug CCS protocols before breakfast

- Wrench warriors who can rebuild a Lucid’s pack blindfolded

- Sales poets explaining why 800V matters to confused Uber drivers

Richter’s Core Training Ecosystem bridges these worlds. Our gear isn’t just tools—they’re Rosetta Stones for the EV age.

Final Thought: The next gen of EV techs won’t just fix cars. They’ll balance microgrids, haggle with utilities, and outsmart battery gremlins. As Mumbai’s trainees say: “Learn on yesterday’s gear, fix today’s cars. Master modern trainers, and you’ll build tomorrow’s industry.”

References

3: Level 3 Charger Safety Standards (2024)

5: National Electrical Code Compliance (2024)

7: Li-ion Cell Balancing Research (Wuhan University, 2024)

8: Inductive Balancing Circuit Study (Scientific Reports, 2024)

12: EV Technician Certification Trends (Global Report, 2025)

14: Charging Protocol Training Modules (ISO 15118)

15: Charging Station Design Case Studies (Shanghai, Nairobi)

16: Battery Pack Testing Equipment Validation (Richter Labs, 2025)

All product details sourced from Richter Automotive Training Solutions.