The rise of electric vehicles (EVs) has transformed the auto repair industry overnight. Gone are the days when mechanical know-how alone could solve most problems. Today, understanding the motor and drive system is just as crucial. Training future technicians requires advanced tools that simulate real electric vehicle motors and drivetrains—this is where Electric Vehicle Motor and Drive System Trainers come into play.

In this article, we’ll break down why these trainers are essential, how they work, and how Richter’s products make hands-on EV education accessible, safe, and effective. Whether you’re running a repair school or a workshop training program, this guide offers insights to keep your skills current and your students ahead of the curve.

Table of Contents

Why Electric Vehicle Motor and Drive System Trainers Matter for EV Education

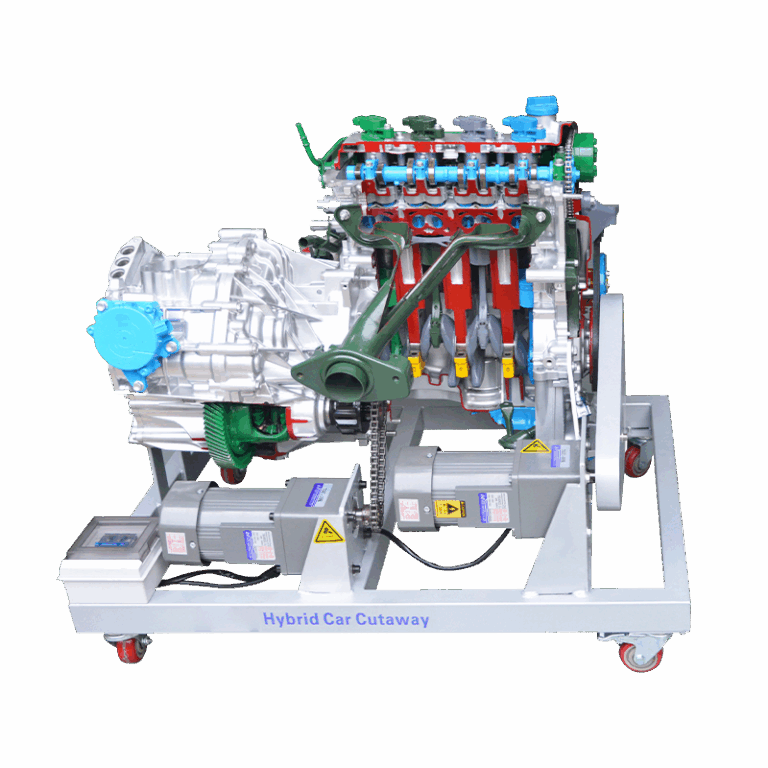

EV motors and drives are high-tech and complex. The drive system includes electric motors, inverters, controllers, and transmission interfaces—all communicating through intricate networks like CAN-BUS.

Here’s why realistic trainers are a must-have:

- Hands-On Learning with OEM-Grade Hardware: Students learn with components that mimic real electric vehicle motors and controllers, not just simplified models.

- Safety First: High voltage and fast-rotating parts mean you can’t just “wing it.” Trainers simulate these systems with built-in safety protocols.

- Fault Injection & Diagnostics: Trainers allow instructors to introduce faults—from sensor failures to communication glitches—letting students practice troubleshooting without risk.

- Software-Hardware Integration: Combining physical trainers with diagnostic software mirrors real-world service bays, teaching both manual skills and digital fault finding.

- Preparation for EV Market Growth: With EV sales skyrocketing, technicians trained on these systems are in high demand.

What Electric Vehicle Motor and Drive System Trainers Cover

| Trainer Type | Focus Area | Richter Examples & Links |

|---|---|---|

| Electric Vehicle Motor Disassembly & Assembly | Motor construction, winding, magnets, bearings | Electric Vehicle Drive Motor Disassembly Trainers |

| Drive System Trainers | Controllers, inverters, motor control algorithms | Electric Vehicle Drive System Trainers |

| Power Chassis Fault Diagnosis | Full drivetrain diagnostics including motor faults | Electric Vehicle Power Chassis Fault Diagnosis Training System |

| High Voltage Control Box Trainers | HV electrical safety, control box assembly/disassembly | Electric Vehicle Original High-voltage Control Box Assembly Disassembly and Testing System |

Real-World Success: How Trainers Improve EV Technician Readiness

A vocational college in Europe integrated Richter’s Electric Vehicle Drive System Trainers into their curriculum. Within a semester, students reported significantly improved understanding of motor controller software and hardware interfaces.

One instructor shared: “Our students no longer feel overwhelmed by the complex CAN communication or inverter functions. They troubleshoot real faults confidently, having practiced with simulated sensor failures and communication errors.”

This hands-on familiarity reduces post-training “on-the-job” errors, saving workshops costly diagnostic time and ensuring higher customer satisfaction.

Industry Jargon That Matters

- Inverter: Converts DC battery power into AC for the motor. Trainers teach how this works and how to diagnose inverter faults.

- CAN-BUS: The communication highway between vehicle modules. Simulated CAN signals help learners understand message flow and fault detection.

- Torque Vectoring: Advanced drive control optimizing power to wheels; trainers allow testing of these complex algorithms.

- Regenerative Braking: Trains on capturing kinetic energy back to the battery, essential for modern EV efficiency.

- High-Voltage Safety Protocols: Safety standards critical for handling EV motors and drives, integrated into Richter’s training systems.

Knowing this language is essential for technicians to master modern EV repair.

Why Choose Richter for Electric Vehicle Motor and Drive Training?

Richter’s solutions are more than just equipment—they’re comprehensive training platforms designed for today’s evolving EV landscape:

- Modularity & Scalability: Mix and match trainers to fit your curriculum, from basic motor assembly to full drivetrain fault diagnostics.

- Integration of Software & Hardware: Diagnostic software enhances physical training, providing a holistic learning experience.

- Robust Build Quality: Designed for repeated educational use, cutting downtime and replacement costs.

- Global After-Sales Support: Installation, training, and maintenance support to keep your program running smoothly.

- Focused on Safety: Trainers incorporate all required safety protocols for high-voltage systems.

Discover Richter’s lineup and how it matches your school’s needs:

- Electric Vehicle Drive Motor Disassembly Trainers

- Electric Vehicle Drive System Trainers

- Electric Vehicle Power Chassis Fault Diagnosis Training System

- Electric Vehicle Original High-voltage Control Box Assembly Disassembly and Testing System

Business Value: The ROI of Investing in Richter Trainers

| Challenge | Traditional Training | Richter Solution | Benefits |

|---|---|---|---|

| Student safety risks | Limited hands-on exposure | Safe simulation and real hardware | Reduced injury risk, safer learning |

| Skill gaps | Theory-heavy, less practice | Fault injection and real diagnostics | More job-ready graduates |

| Equipment wear & costs | Frequent part replacements | Durable, modular trainers | Lower replacement & maintenance cost |

| Training scalability | Instructor-dependent, limited capacity | Self-paced with software integration | Higher throughput, reduced instructor load |

Richter’s trainers help institutions save costs while delivering high-impact, industry-ready skills.

The Road Ahead: VR, AI & Remote EV Training

Richter stays ahead by developing next-gen training solutions integrating VR and AI. Imagine remote troubleshooting guided by AI tutors or immersive VR labs replicating EV motor internals in 3D. These advancements promise to revolutionize how technicians learn and maintain EVs.

Final Thoughts: Equip Your Technicians for the EV Revolution

Electric vehicle motor and drives are at the core of future mobility. To train technicians capable of servicing these advanced systems, schools and workshops need realistic, safe, and integrated trainers.

Richter’s extensive product range covers everything from motor disassembly to full drivetrain diagnostics. Investing in these tools ensures your learners gain confidence, hands-on skills, and up-to-date knowledge—making them indispensable in today’s EV market.

Explore Richter’s offerings today and power your training into the future.