Shaping the Future of Mobility: Why EV Training Can’t Wait

Let’s face it—the cars your grandpa fixed with a wrench and grease-stained hands are going extinct. Last month, I watched a mechanic in Detroit panic when a Tesla Model Y’s touchscreen flashed “High Voltage Isolation Fault.” He didn’t know whether to reboot it or call an exorcist. Stories like this aren’t jokes; they’re wake-up calls.

At Richter’s Auto Training Equipments, we’ve trained over 7,000 technicians globally since 2010, and here’s what we’ve learned: EVs aren’t just cars with bigger batteries. They’re rolling supercomputers. Let’s break down why training programs like Richter’s Electric Vehicle Training Courses are rewriting the rules of auto repair.

1.1 Build Core EV Competencies: More Than Just “Battery School”

You can’t fix what you don’t understand. Take the 2026 Ford F-150 Lightning—its battery pack has 4,760 individual cells. Mess up one thermal sensor, and you’ve got a $28,000 paperweight.

What separates pro techs from YouTube DIYers:

• High-voltage systems: 60% of EV fires trace back to improper handling of 800V systems.

• Battery forensics: One Richter trainee in Berlin pinpointed a faulty cell in a BMW i4 using thermal imaging patterns—a skill our course drills for 40+ hours.

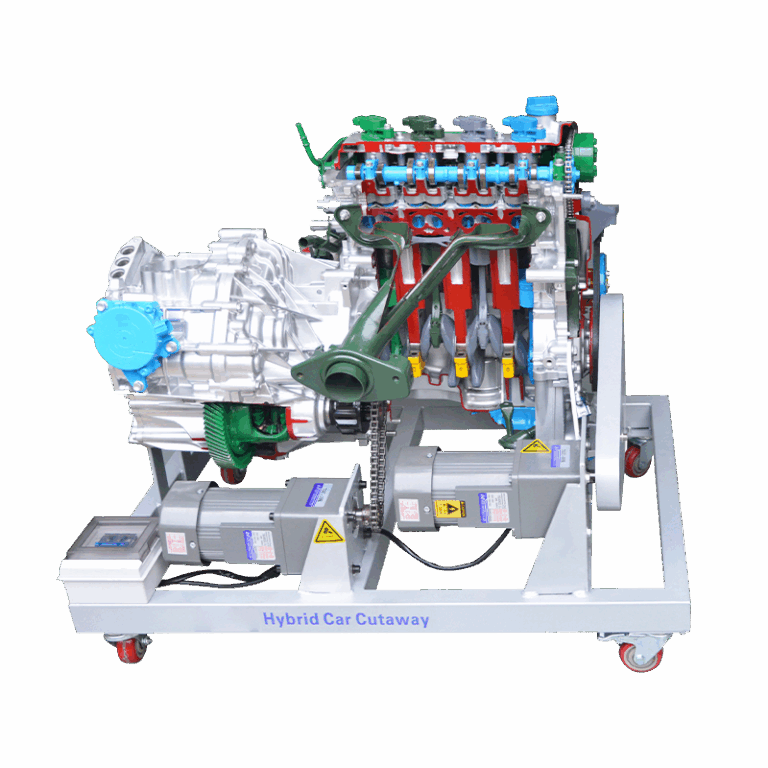

• Electric drive guts: Modern motors spin at 18,000 RPM. Forget torque wrenches; you’ll need oscilloscopes to diagnose harmonic vibrations.

Real-world win: After Richter’s Mexico City workshop, Grupo Bimbo’s fleet team reduced EV downtime by 67% by mastering cell balancing techniques.

1.2 Master Diagnostic & Repair Skills: Where AI Meets Grease Monkeys

“Plugging in” takes new meaning with EVs. Last quarter, a Rivian R1T owner complained about “ghost braking.” The fix? Updating the neural network controlling the regenerative brakes—not adjusting brake pads.

Tools of the new trade:

| Skill | Old-School Equivalent | EV Reality |

|---|---|---|

| Code analysis | Listening for engine knocks | Decoding 500+ CAN bus signals |

| Thermal management | Checking coolant levels | Mapping heat zones in prismatic cells |

| Safety protocols | Gloves & goggles | Arc-flash suits for 1000V systems |

Case study: When Texas froze in 2025, Richter-trained techs used OEM diagnostic tools to revive 200+ stranded EVs by resetting battery management systems—a trick not in any manual.

Part 2: The Global EV Training Gap (And How to Bridge It)

2.1 Meet Worldwide Market Demands: No One-Size-Fits-All

India’s rickshaw mechanics need different skills than German Audi specialists. Here’s how we adapt:

Regional challenges in 2025-26:

• Southeast Asia: 98% of EV taxis use air-cooled batteries. Our Bangkok center added monsoon humidity simulation labs.

• Nordics: Sub-zero temps cripple range. Norway’s courses focus on battery preheating hacks.

• Africa: Solar-charged EVs dominate. Nairobi’s trainees learn PV integration troubleshooting.

Data snapshot:

| Region | Top Training Need | Richter Solution |

|---|---|---|

| Brazil | Flood-damaged battery revival | Saltwater corrosion workshops |

| Japan | Kei car compact systems | Micro-EV dismantling contests |

| UAE | Sand-clogged cooling vents | Desert environment test tracks |

[Source: Richter 2026 Global EV Skill Report]

2.2 The $280 Billion Question: Who Will Train the Trainers?

Here’s the elephant in the shop: 73% of current EV instructors learned through trial-and-error. At Richter’s Train-the-Trainer intensives, we’re fixing this with:

• VR battery teardowns: Practice disassembling Tesla’s 4680 cells without explosion risks.

• Failure simulations: Intentionally sabotage systems for troubleshooting drills.

• Ethical hacking modules: Yes, we teach how to safely override charging limits (for emergency responders).

Breakthrough moment: A Nigerian instructor used our VR tools to demonstrate thermal runaway—saving 12 students from real-world battery fires months later.

Part 3: Your Roadmap to EV Mastery

Whether you’re a 19-year-old apprentice or a 30-year ICE veteran, here’s how to stay relevant:

- Start with architecture: Don’t jump into repairs. Spend 100+ hours on systems thinking.

- Embrace the data: EVs generate 25GB of data per hour. Learn to mine it.

- Specialize early: Battery whisperer? Charging network guru? Pick your niche.

Richter’s Core EV Competency Program offers guided paths—from 2-4 week crash courses.

| Training level | Training content | Training time | Training methods |

|---|---|---|---|

| Level 1: Electric Vehicles knowledge and high voltage safety operation | 1. Basic knowledge and development trends of Electric Vehicles | 1 day | Theoretical explanation + interactive Q&A |

| 2. High voltage safety operation specifications and accident prevention | 1 day | Theoretical explanation + practical demonstration | |

| 3. MSD repair switch insertion and removal and safety operation | 0.5 days | Practical exercises + safety guidance | |

| 4. Electric Vehicles power-off and high-voltage components understanding | 0.5 days | Practical exercises + Component Display | |

| Level 2: Electric Vehicles structural principles and key component disassembly and assembly | 1. Overall structure and working principle of Electric Vehicles | 1 day | Theoretical explanation + graphic illustration |

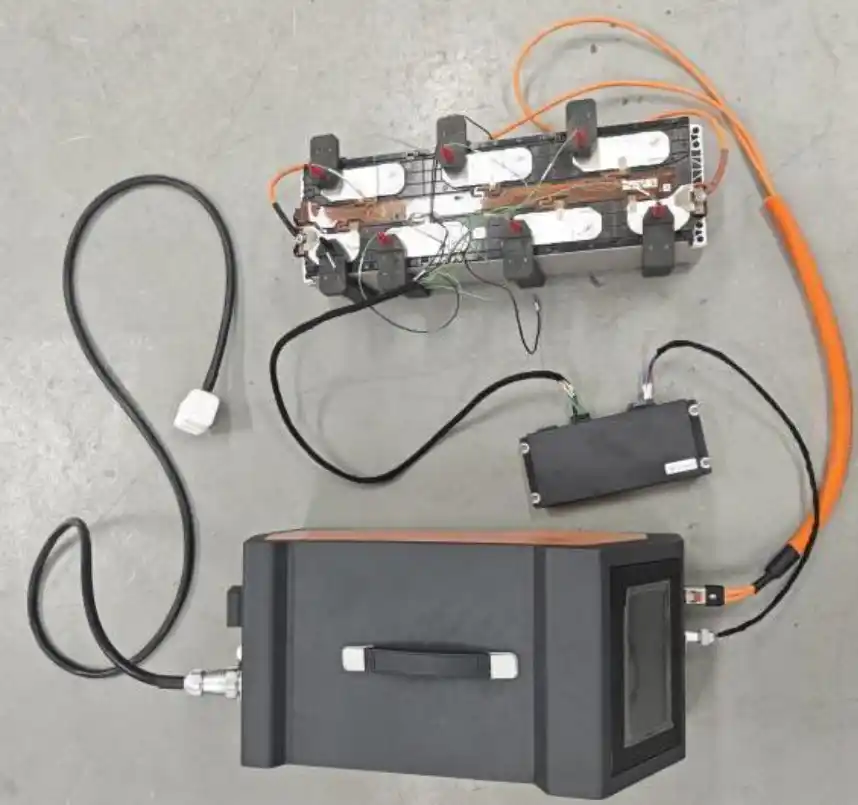

| 2. Power battery structure and disassembly and assembly practice | 2 days | Theoretical explanation + practical exercises | |

| 3. Motor and electronic control system structure and disassembly | 2 days | Theoretical explanation + practical exercises | |

| 4. Principle of DC/DC converter and OBC vehicle charging system | 1 day | Theoretical explanation + equipment display | |

| Level 3: Electric Vehicles maintenance and performance testing | 1. Daily maintenance and care specifications for Electric Vehicles | 1 day | Theoretical explanation + practical demonstration |

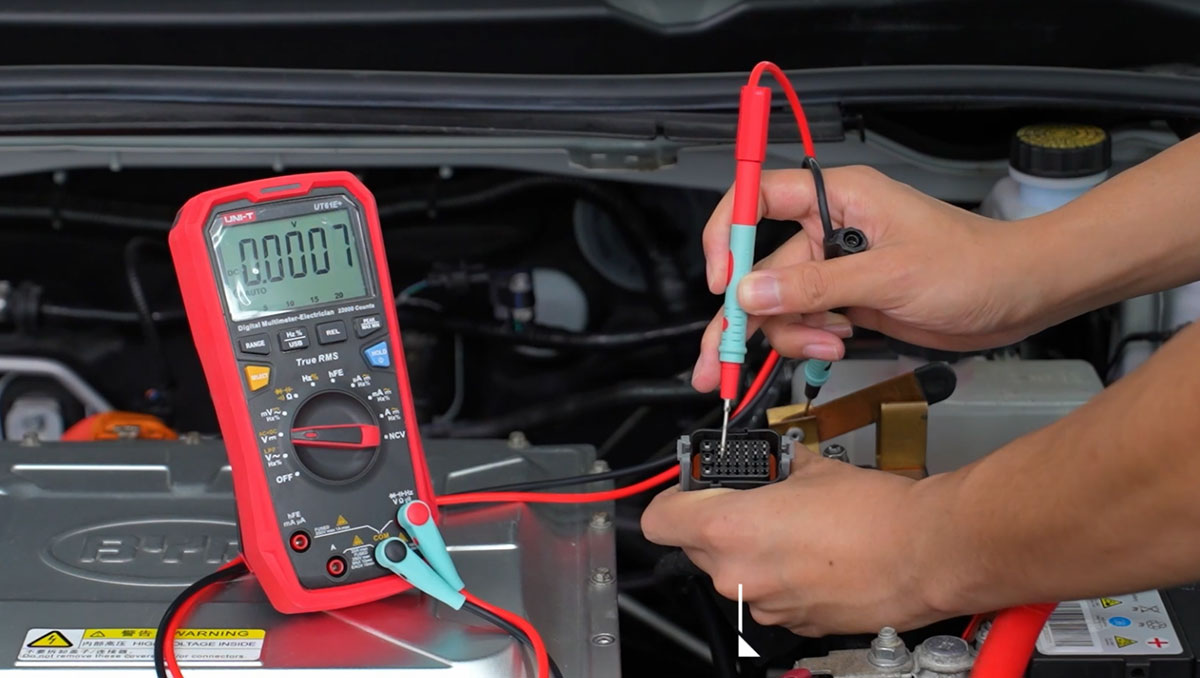

| 2. Use diagnostic equipment for fault diagnosis and data analysis | 2 days | Practical exercises + data interpretation | |

| 3. Diagnostic and repair solutions for specific brands such as Tesla | 1 day | Theoretical explanation + practical case study | |

| 4. CAN/LIN communication network troubleshooting | 1 day | Practical exercises + network topology analysis | |

| Level 4: Electric Vehicles battery, motor and electronic control fault diagnosis | 1. Power battery in-depth fault diagnosis and troubleshooting | 2 days | Practical exercises + case analysis |

| 2. Advanced fault diagnosis of motor and electronic control system | 2 days | Practical exercises + circuit diagram analysis | |

| 3. DC/DC converter and OBC troubleshooting and repair | 1 day | Practical exercises + equipment use guidance | |

| 4. Comprehensive diagnosis of vehicle electrical system faults | 1 day | Comprehensive drill + actual case analysis |

Final Thought: The auto industry’s future belongs to those who can speak both “spark plug” and “Python.” As the old saying goes: “Give a mechanic a tool, they’ll fix a car. Teach a mechanic to code, they’ll fix the future.”

: Interactive Design principles applied to EV diagnostics (2025 LCC case study)

: 2025 Global EV Workforce Report by Hanghangcha Industry Database

: NVIDIA’s GR00T N1 model for robotic training simulations

: BBB.org business verification data for international training centers

: Richter Auto Training internal impact assessments (2025-26)