Overview

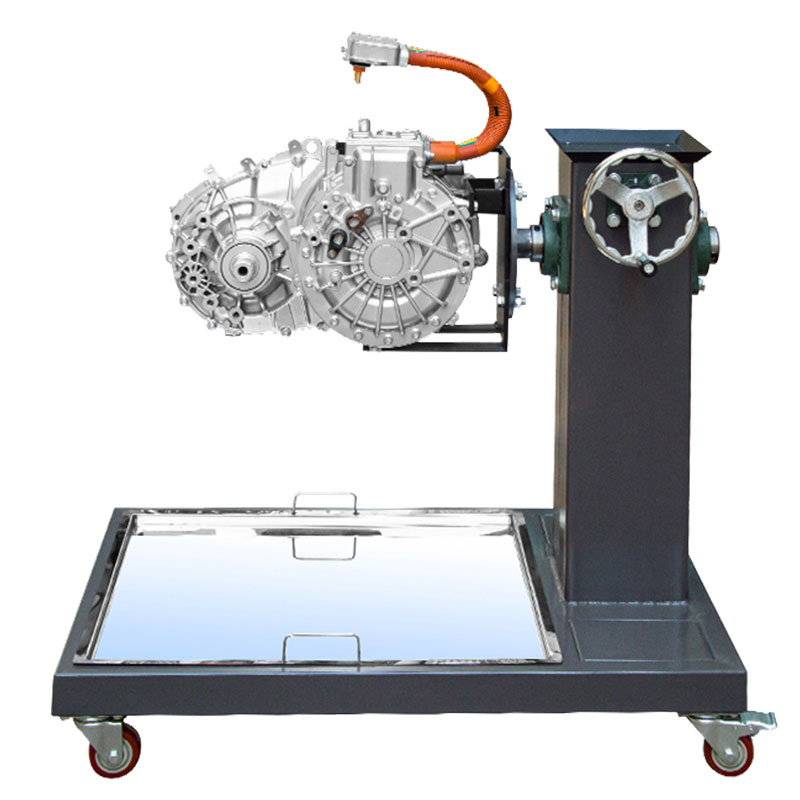

This trainer is engineered for comprehensive instruction in electric vehicle drive systems. It features a complete drive motor assembly sourced from new energy vehicles, designed for effortless disassembly and reassembly. Integrated within a specially engineered turnover frame, the unit offers a dynamic learning environment where students can work from any angle, thanks to a deceleration turnover mechanism that allows smooth rotation and secure positioning. This flexibility enables learners to explore intricate motor components in a practical, real-world setting.

Key Features and Advantages

360° Accessibility:

The specially designed turnover frame with a deceleration turnover mechanism enables students to rotate and lock the transmission at any angle. This feature ensures an optimal view of the drive motor assembly during disassembly and reassembly exercises.Efficient Component Management:

An integrated oil pan is positioned at the bottom of the frame, serving as a convenient storage solution for small parts and screws. This design not only minimizes the risk of losing essential components but also streamlines the instructional process.Robust Construction:

Crafted from high-strength steel tubes (60×40×3mm) and welded into a durable turnover frame, this trainer is built to withstand rigorous educational environments. The surface is professionally treated with a high-quality spray process for enhanced longevity.Enhanced Mobility:

Equipped with four self-locking casters (front two with locking functionality and rear two swivel casters), the trainer is easily movable, making it ideal for diverse classroom settings and training workshops. The casters are securely fixed with M6*4 screws, ensuring stable and reliable operation.OEM Drive Systems:

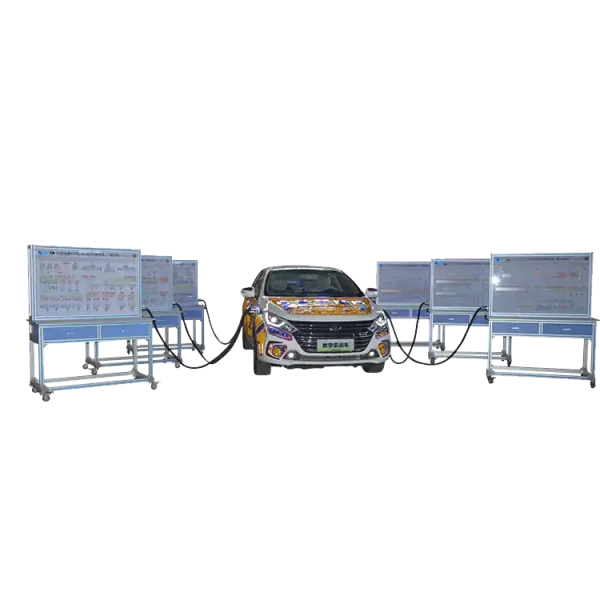

The trainer is compatible with industry-standard drive systems, including Geely Emgrand and BYD drive systems, providing learners with authentic, real-world component exposure.

Technical Specifications

- Equipment Dimensions: 1000×600×1100 mm (L×W×H)

- Steel Tube Dimensions: 60×40×3 mm

- Caster Details:

- Caster Dimensions: 60 mm (Diameter) × 50 mm (Width)

- Front Casters: Locking function for increased stability

- Rear Casters: Swivel design for enhanced maneuverability

- Reducer Model: MOPA70; Ratio: 1:70

Value for Students and Instructors

For Students

Practical, Hands-On Experience:

By engaging with a complete electric vehicle drive motor assembly, students gain invaluable, practical experience in both disassembly and reassembly processes.Enhanced Diagnostic and Troubleshooting Skills:

The modular design and easy accessibility of components foster an in-depth understanding of electric drive systems, preparing students for real-world automotive challenges.Adaptability in Learning:

The trainer’s ability to rotate and lock at various angles offers multiple viewing perspectives, reinforcing learning through comprehensive component analysis.

For Instructors

Simplified Demonstration:

The well-organized control panel and clearly labeled wiring diagrams make it straightforward for instructors to demonstrate complex procedures and highlight critical system functionalities.Durable and User-Friendly Design:

The robust construction and mobile design allow for concurrent use by multiple students, facilitating group discussions and collaborative learning without compromising safety.Quick Setup and Maintenance:

With its plug-and-play design and integrated self-locking castors, the trainer requires minimal preparation, enabling instructors to focus on delivering quality training.

Conclusion

Richter’s Electric Vehicle Drive Motor Disassembly Trainer is a state-of-the-art training solution designed to meet the demands of modern automotive and electric vehicle education. By integrating real-world components with innovative design features, this trainer empowers both students and instructors to explore and master the intricacies of electric drive systems. Whether in universities, vocational schools, or automotive training centers, our equipment is engineered to provide an engaging, hands-on learning experience that aligns with industry standards and technological trends.

For more information about our innovative training solutions—including Automotive Trainers, Electric Vehicle and Hybrid Trainers, Simulation Training Software, Smart Manufacturing Software, and comprehensive Training Services—please visit our website and join the global community of automotive professionals advancing their skills with Richter.