Overview

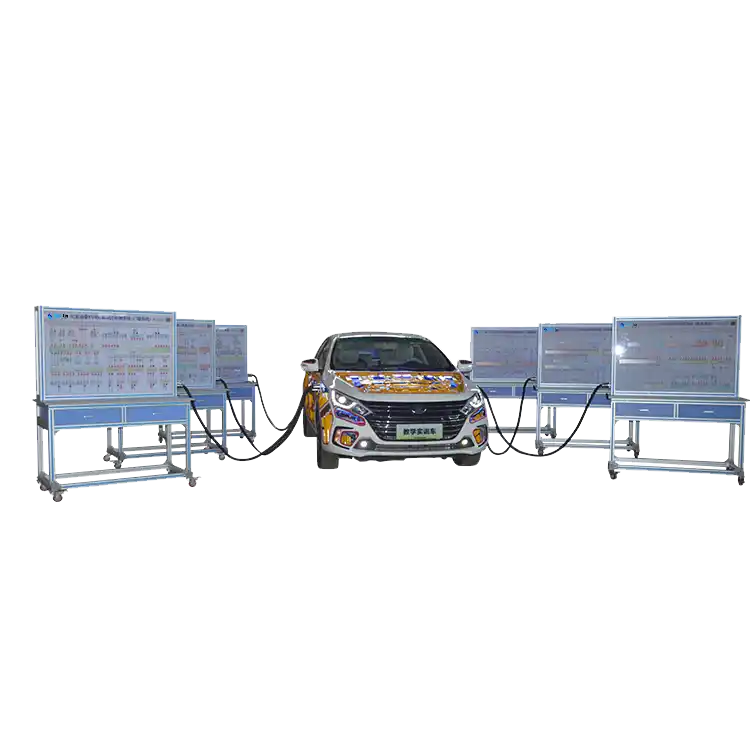

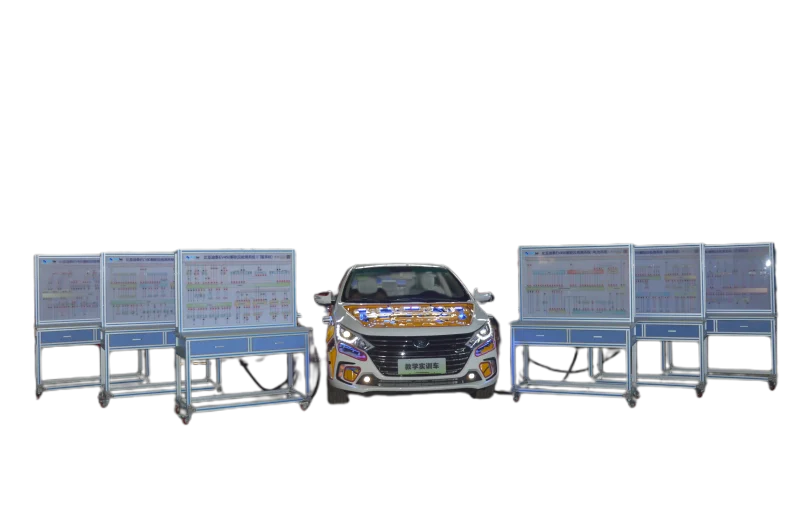

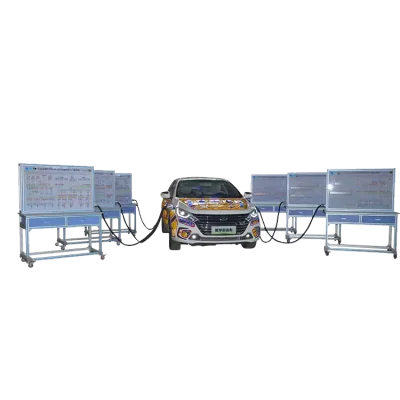

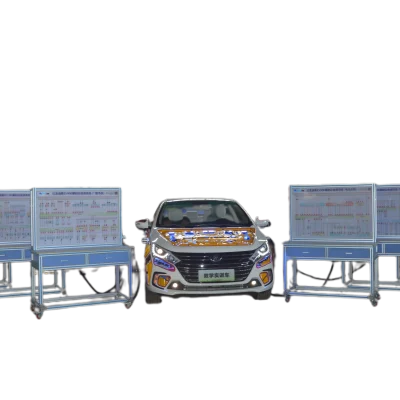

The Full Vehicle Dissection and Testing System is an advanced Electric Vehicle System Trainer built on a pure electric vehicle platform. This state-of-the-art training system offers a realistic, real-time learning environment through six dedicated detection panels that continuously monitor sensor and actuator performance. With a design that preserves the vehicle’s original configuration and functionality, this trainer provides an intuitive understanding of modern electric vehicle systems while retaining the complete operational integrity of the vehicle.

Key Functional Features

Comprehensive Vehicle Dissection

The system utilizes a large-area sectional design on the body covering, exposing key high-voltage and power system components without causing damage. This method ensures that the vehicle maintains its original functionality, enabling it to be driven on the ground even after dissection.Integrated Circuit Detection

Each of the six detection panels is linked to a dedicated detection bench. These panels monitor the entire circuit schematic of the vehicle, covering the battery management, charging, driving, air conditioning, steering, ABS, lighting, and wiper systems. Measurements such as resistance, voltage, frequency, and waveform are easily obtained using common diagnostic tools like multimeters and oscilloscopes.Advanced Self-Diagnosis Capability

Easily connect the trainer to both specialized and general vehicle decoders. The system supports essential self-diagnosis functions, including fault code reading, clearing fault codes, and monitoring data flow, making it an indispensable tool for troubleshooting and diagnostics.Durable and High-Performance Design

The measuring panels are crafted from high-strength acrylic, offering excellent resistance to temperature variations, abrasion, moisture, and corrosion. The robust training platform is constructed from international standard aluminum alloy profiles, ensuring a lightweight, high-strength, and visually appealing design. Equipped with a self-locking castor device, the platform is mobile, safe, and built to withstand daily educational use.

Benefits for Students

Real-World Learning Experience

Students engage with a full-scale electric vehicle system that mirrors real-world environments. This hands-on experience enhances understanding of the inner workings of electric vehicles, from battery management to power system diagnostics.Enhanced Diagnostic Skills

The integrated detection panels and self-diagnosis functions allow students to monitor system performance in real time, practice fault identification, and develop effective troubleshooting skills.Interactive and Intuitive Operation

With clear circuit schematics and accessible detection terminals, learners can easily measure and analyze sensor outputs, making the learning process both interactive and effective.

Benefits for Instructors

Authentic OEM Experience

Utilizing components from the original vehicle, the system offers an authentic learning platform where instructors can demonstrate real-world automotive systems and diagnostic processes.Simplified Demonstration and Maintenance

The intact relative positioning of vehicle accessories and the plug-and-play design reduce setup time, allowing instructors to focus on teaching critical diagnostic techniques without extensive preparation.Enhanced Collaborative Learning

The trainer’s design supports concurrent use by multiple students, fostering an interactive, collaborative classroom environment that encourages teamwork and peer learning.

Technical Specifications

- Product Dimensions: Approximately 4700 x 1800 x 1600 mm (Length × Width × Height)

- Operating Power Supply: 12V DC and/or Original Vehicle High Voltage Battery Pack

A Trusted Partner in Education

At Richter, our mission is to provide cutting-edge automotive trainers and electric vehicle system trainers that elevate technical skills and support educational excellence. Our comprehensive portfolio, including Automotive Trainers, Electric Vehicle and Hybrid Trainers, Automotive Simulation Training Software, Smart Manufacturing Software, and Training Services, is designed to meet the diverse needs of universities, vocational schools, training centers, and repair companies worldwide.

Experience the future of automotive and electric vehicle training with the Full Vehicle Dissection and Testing System – a state-of-the-art tool engineered to empower both instructors and students with practical, hands-on skills for today’s rapidly evolving automotive industry.