Richter’s Tolerance and Measurement Technology VR Training Software is an advanced educational tool designed to bring the complex principles of mechanical tolerance fitting and measurement to life. This software, specifically tailored for mechanical engineering students in secondary and vocational colleges, utilizes cutting-edge VR technology to transform abstract concepts into high-definition 3D models, animations, and interactive exercises. By combining theoretical learning with hands-on training, this VR software provides an engaging and effective learning experience that is not constrained by time, location, or physical resources.

Key Features

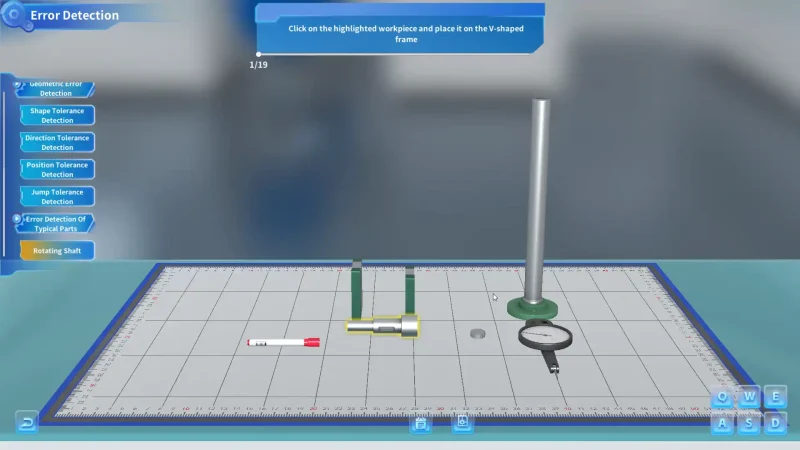

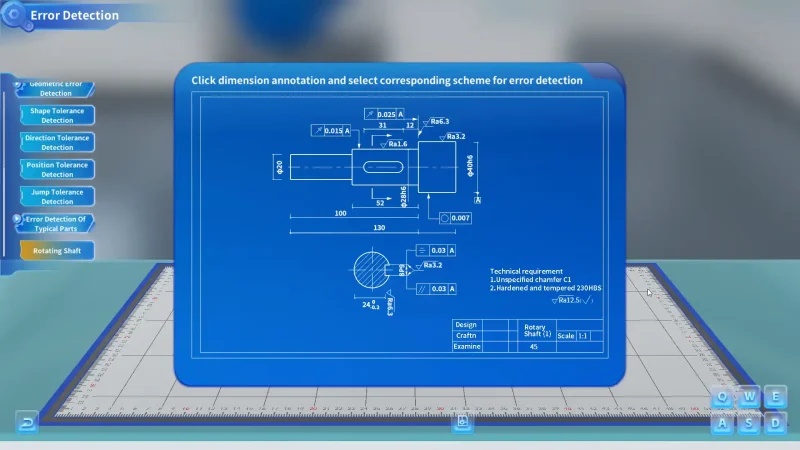

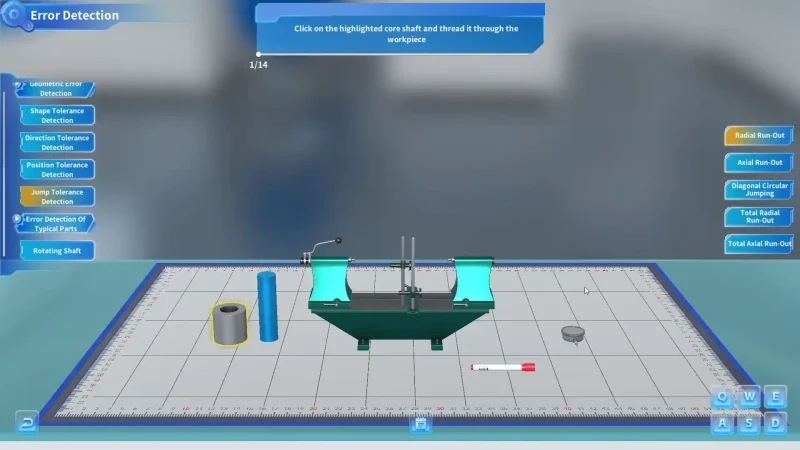

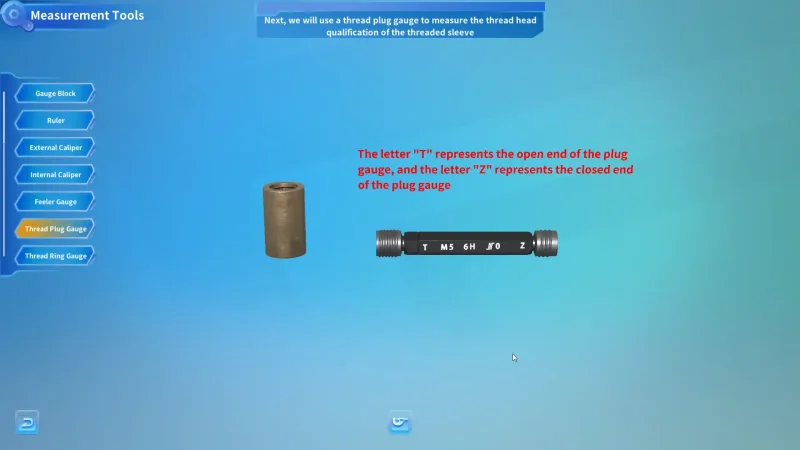

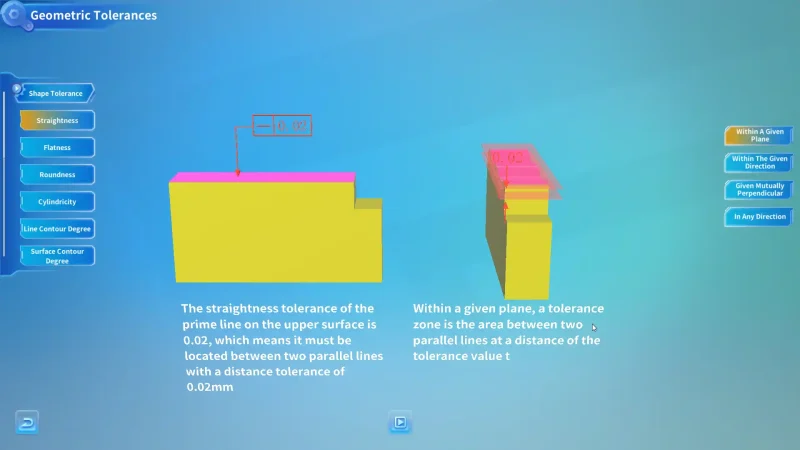

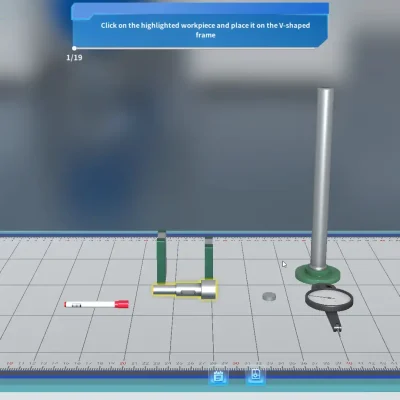

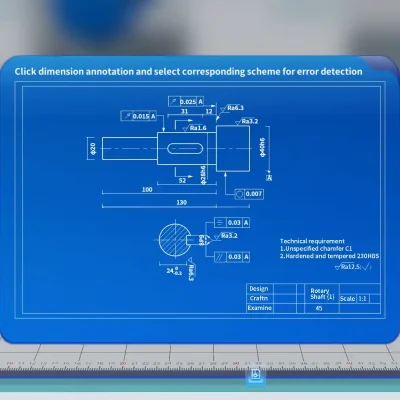

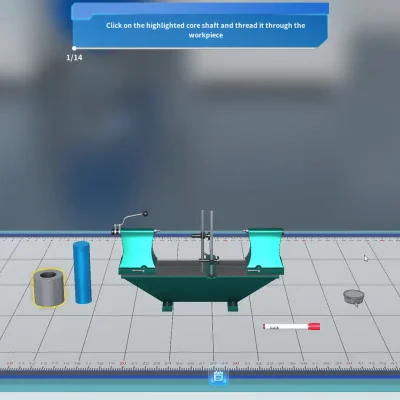

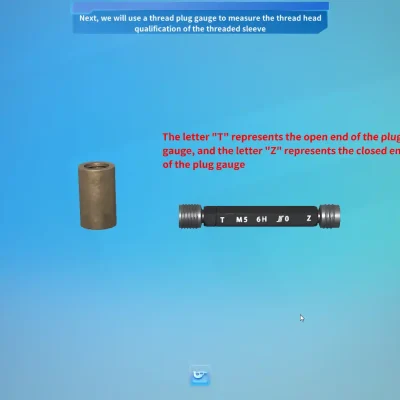

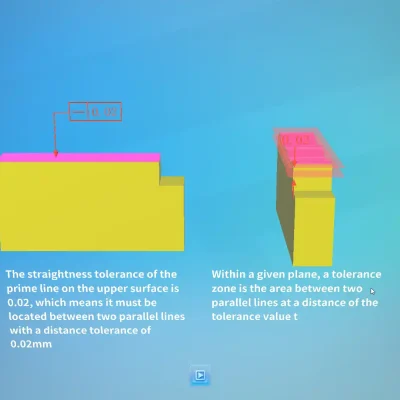

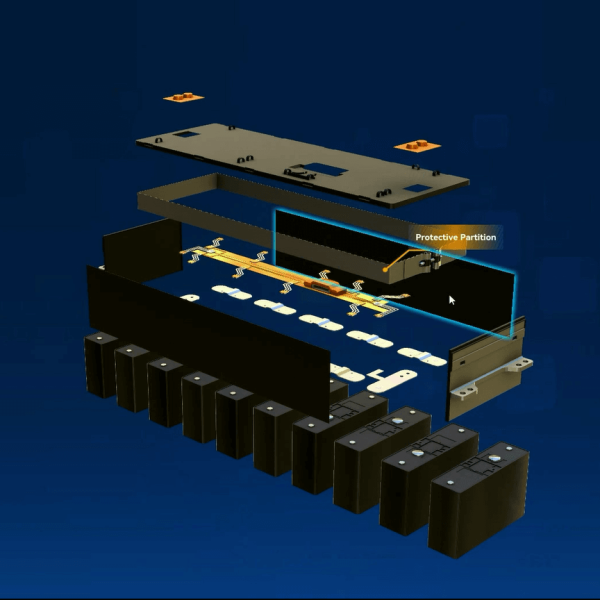

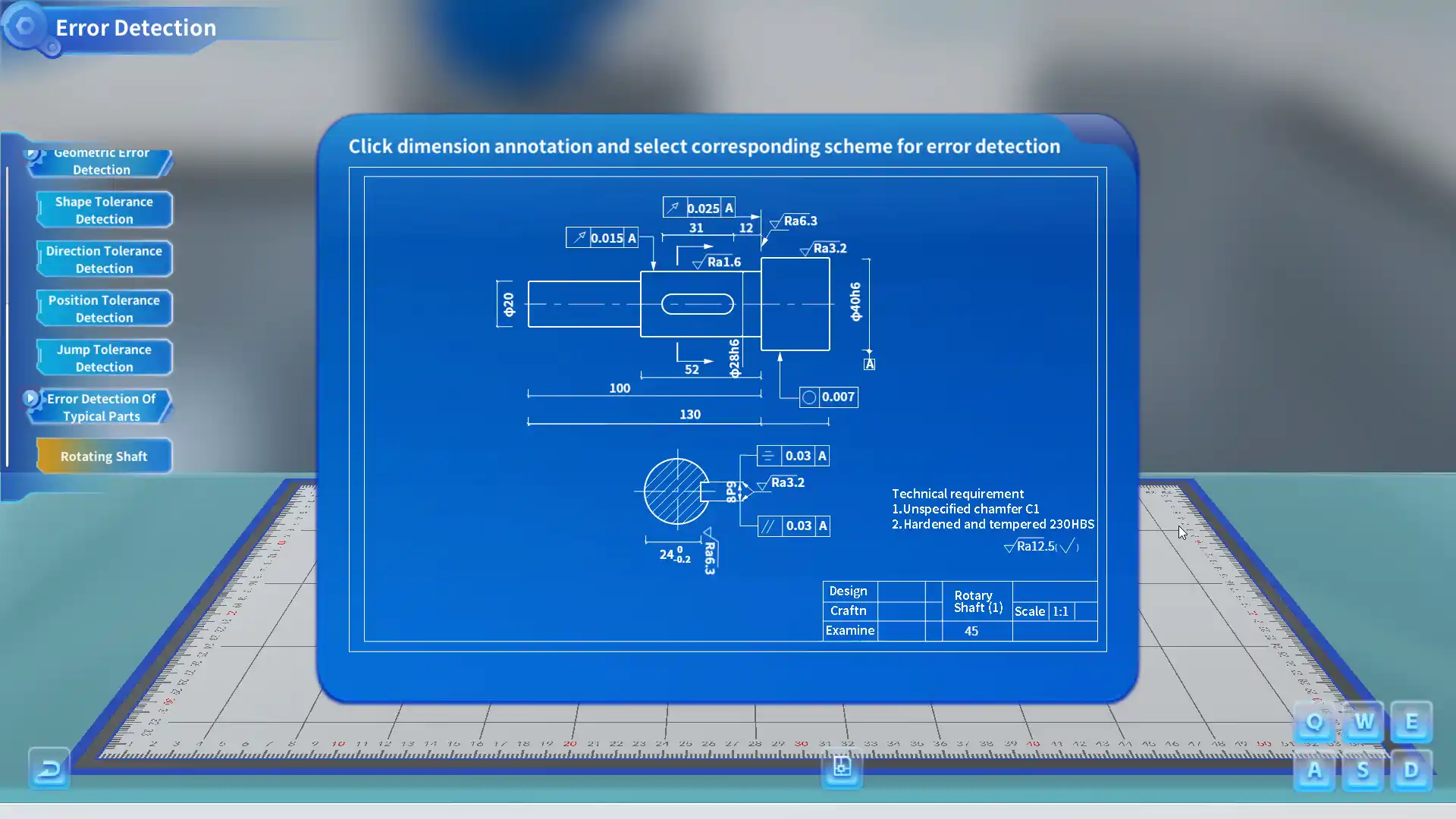

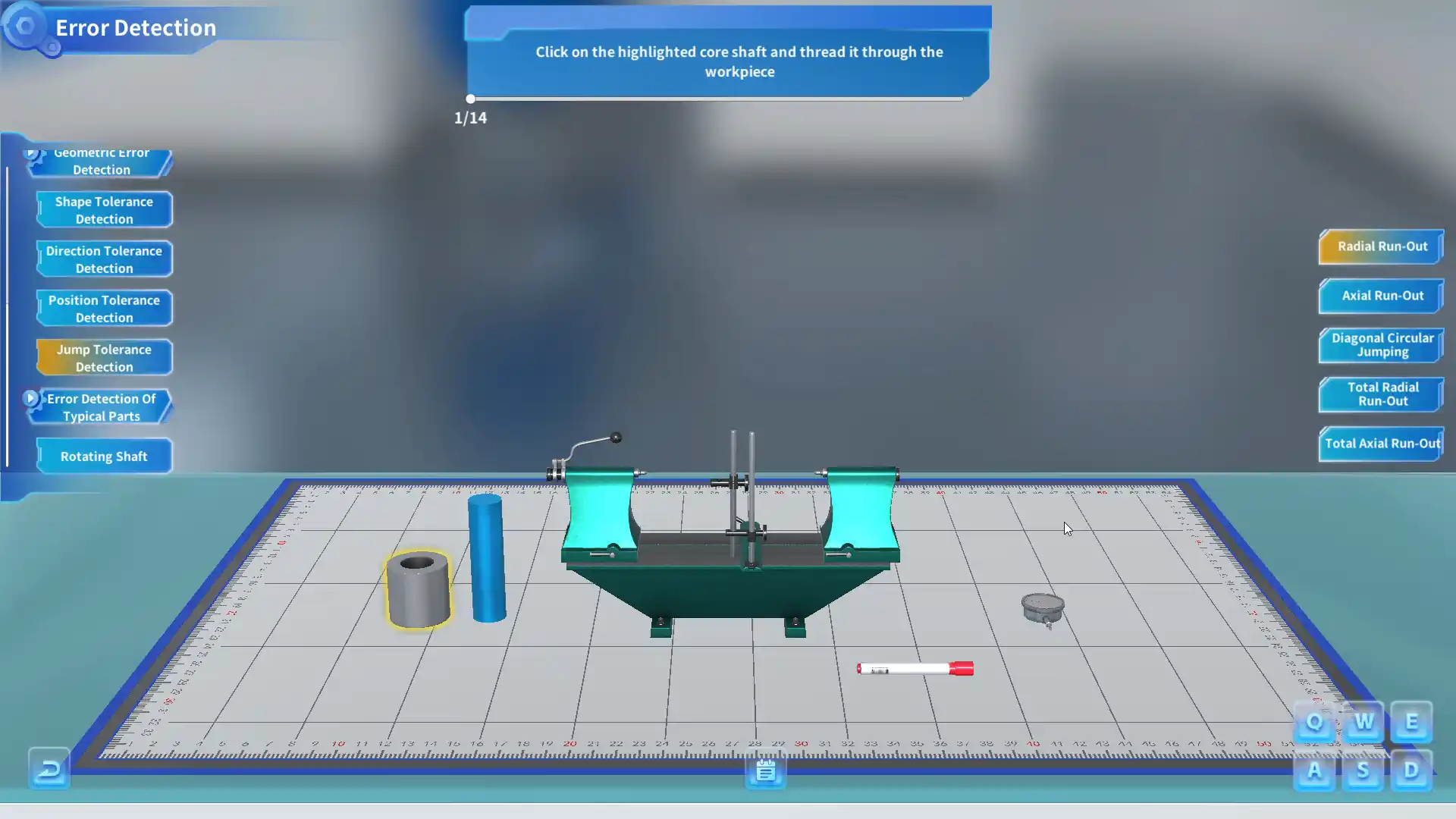

- Comprehensive Training Modules: The software includes practical training and assessment modules, ensuring students learn through both practice and examination. These modules cover a wide range of mechanical tolerance fitting and measurement processes such as surface roughness detection, thread detection, gear detection, and geometric error detection.

- Interactive Learning: Students can interact with 3D models, rotating, dragging, and zooming in on different components. This interactivity helps deepen the understanding of key concepts and fosters a more engaging learning environment.

- VR-Enhanced Learning: The use of virtual reality allows students to visualize and engage with difficult-to-understand concepts in a more accessible manner, improving knowledge retention and providing real-world applications for mechanical tolerance fitting.

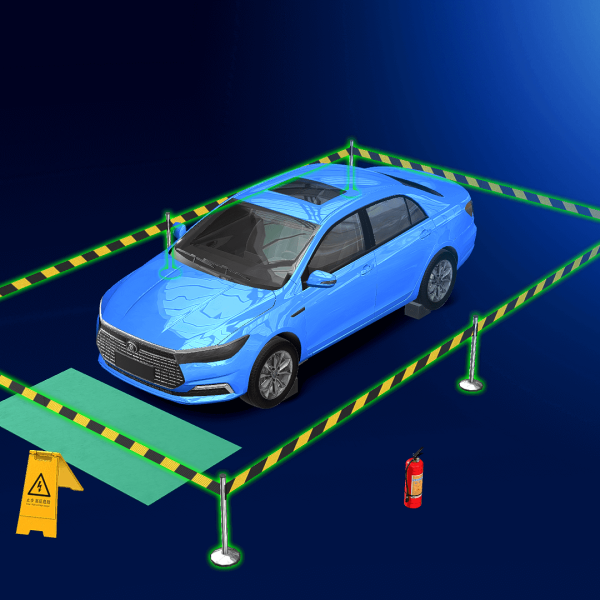

- Simulated Training Environment: The software simulates real-world training environments without the constraints of physical equipment. This virtual approach helps mitigate the challenges of location and availability of tools, enabling students to practice at any time and place.

- Assessment Mode: In addition to practical training, the software includes a built-in assessment feature that allows students to take exams and track their progress. This ensures that students can measure their understanding of the material as they progress through the curriculum.

- Compatibility: The software is compatible with a range of hardware devices, including all-in-one machines and PCs, ensuring flexibility in usage across various educational settings.

Benefits for Students

- Enhanced Understanding: The VR technology enables students to explore mechanical tolerance fitting and measurement in a 3D space, helping them understand complex concepts that are typically challenging in traditional classrooms.

- Practical Training Anytime, Anywhere: Students are no longer limited by the availability of physical equipment or classroom space. They can engage with the software whenever and wherever they choose, offering flexibility in learning.

- Increased Engagement: Interactive animations and real-time feedback make learning more engaging, motivating students to explore different aspects of mechanical tolerance measurement while improving their skills.

- Safe Learning Environment: The software provides a risk-free environment for students to practice and make mistakes, without the potential hazards of working with physical tools or machinery.

Benefits for Educators

- Streamlined Training Process: Instructors can use the software to demonstrate mechanical fitting and measurement processes without the need for costly physical setups, reducing both time and resource requirements.

- Consistent Teaching Quality: By using standardized VR modules, educators can ensure that all students receive a consistent and high-quality learning experience, regardless of time or place.

- Enhanced Assessment and Tracking: The built-in assessment module allows instructors to track student progress, identifying areas where additional instruction may be needed. This feature ensures more personalized support for students.

- Improved Safety: By eliminating the risks associated with physical training, educators can provide a safer learning environment, reducing accidents and injury.

Application Scenarios

- Applicable Majors: Primarily designed for mechanical engineering and related fields, the software is ideal for students pursuing careers as mechanical designers or production engineers.

- Course Integration: The software is suitable for courses such as Mechanical Processing Design, Mechanical Manufacturing and Repair, and Fundamentals of Mechanical Design.

- Training Locations: It can be used in educational institutions, including universities, vocational schools, and training centers, to enhance the learning experience of students pursuing careers in mechanical engineering.

Specifications

- Device Compatibility: Works with all-in-one machines and PC computers.

- Security: High level of security to prevent risks in virtual training, providing a safe environment for students to engage in hands-on activities.

- Interactive Functions: Supports model manipulation via dragging, rotating, and zooming, with synchronization of mouse operations.

- Training Modes: The software is divided into “practical training” and “assessment,” ensuring that students can learn progressively from easy to challenging tasks.

Core Functionality

- Comprehensive Tolerance and Measurement Training: The software guides students through every aspect of mechanical tolerance fitting and measurement, including error detection processes and real-time simulation of mechanical systems.

- Flexible Learning Environment: Students can practice anytime and anywhere, unaffected by physical space constraints, while instructors can provide consistent, high-quality training experiences.

For more information about this product and to enhance your educational tools with VR technology, visit Richter’s website. We’re committed to providing innovative solutions to help educators and students excel in the fast-evolving world of mechanical engineering and manufacturing.