The Turning Technology Virtual Simulation Teaching System is a cutting-edge educational tool designed to elevate students’ practical knowledge and operational abilities in machining. This system simulates real-world turning processes and provides an engaging, risk-free environment for learners to develop crucial machining skills. It includes two primary modes: Practical Training Mode and Assessment Mode, enabling students to gain hands-on experience while building a solid foundation in turning operations.

Key Features:

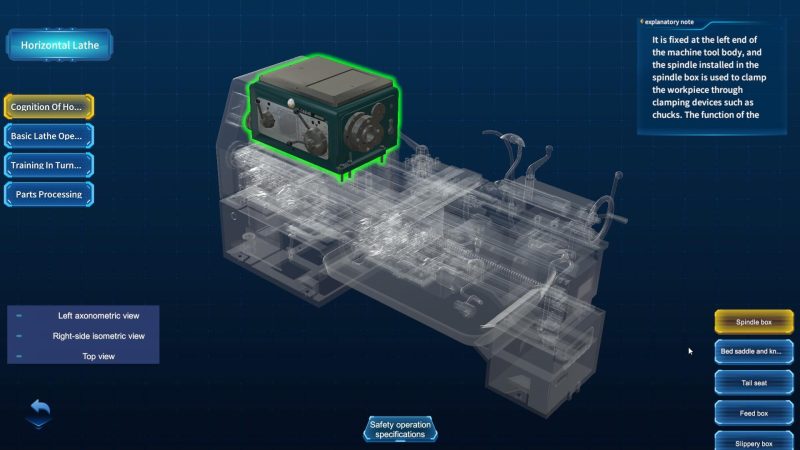

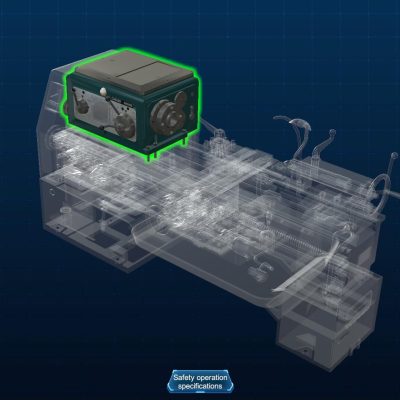

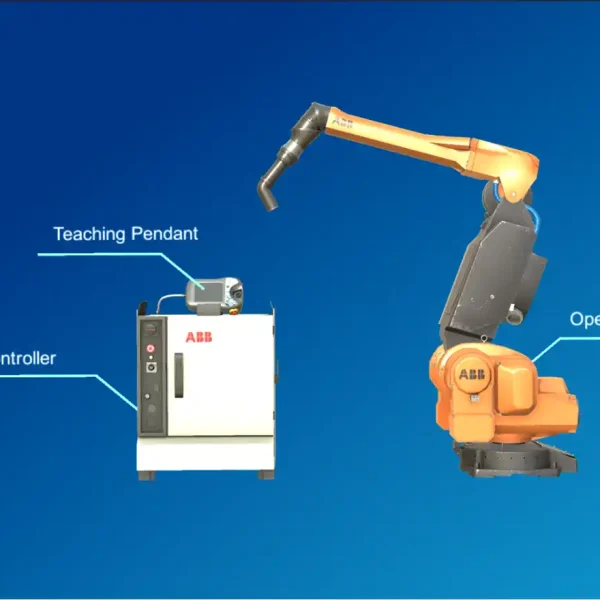

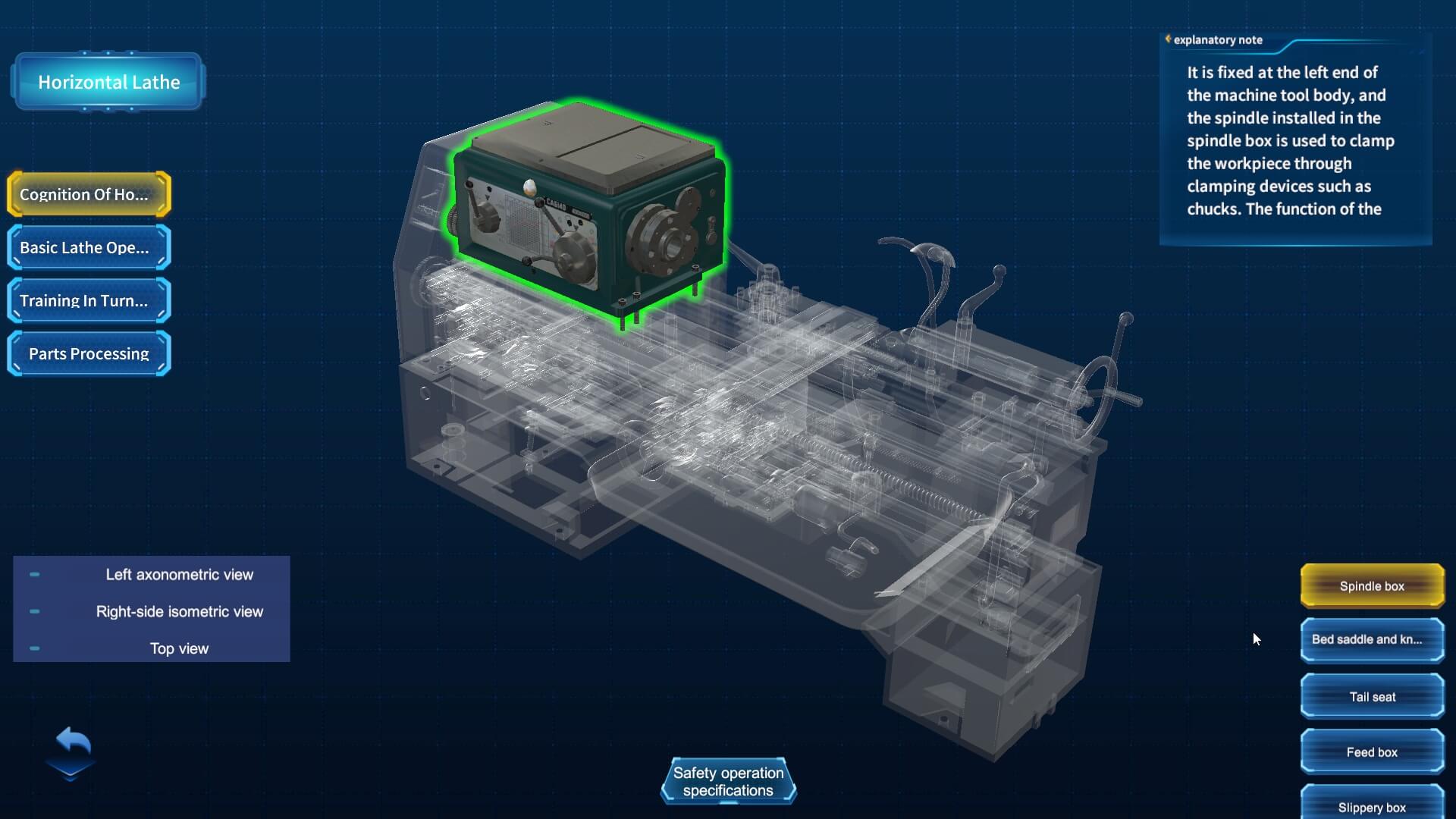

Immersive 3D Virtual Simulation:

Experience realistic, real-time 3D models of machines, tools, and components. The system replicates turning processes, offering an interactive and immersive learning experience that mimics real-world operations.Comprehensive Training Modules:

The system is divided into practical and assessment modes:- Practical Training Mode covers tool, fixture, and gauge recognition, along with horizontal and vertical lathe awareness.

- Assessment Mode evaluates students’ proficiency in machining horizontal shafts, conical parts, threaded components, and disc-shaped parts.

Step-by-Step Task Guidance:

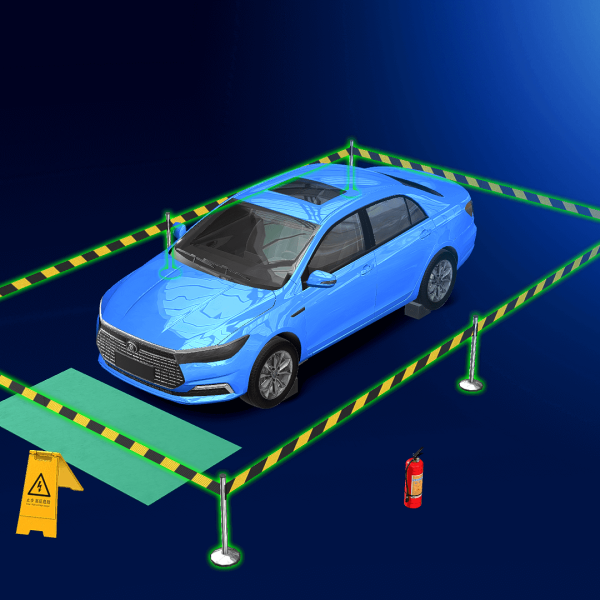

Each mode includes detailed, interactive simulations with visual instructions, guiding students through each process. This hands-on approach enhances understanding while reducing the risk of accidents.Safety Compliance and Virtual Risk Simulations:

The system integrates virtual risk scenarios like tool breakage and improper clamping, ensuring that learners understand safety protocols while working through simulations. This allows for error-free learning in a controlled virtual environment.Data-Driven Performance Feedback:

Receive detailed performance reports after each task to track progress, identify areas for improvement, and provide constructive feedback to guide the learning process.Cross-Platform Access:

Whether on a PC or VR headset, the Turning Technology Virtual Simulation Teaching System is designed to offer flexible learning opportunities. Train anytime, anywhere with seamless access.Modular Training Structure:

With separate modules for tools, fixtures, gauges, and lathe operations, the system allows learners to focus on individual components before advancing to full assessments.Realistic Physics Engine:

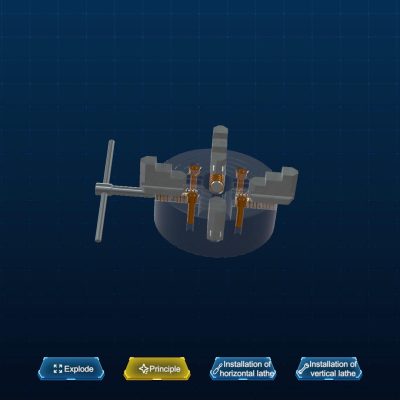

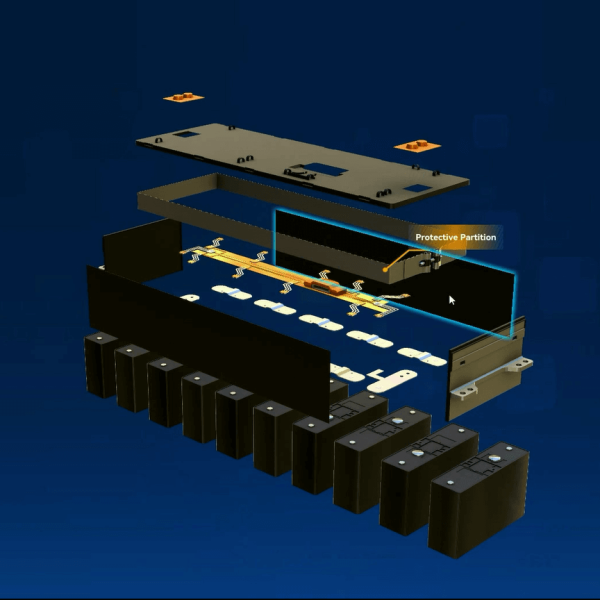

The system replicates real-world machining forces, material behavior, and physical dynamics, allowing students to experience machining operations as they would occur in the industry.Disassembly-Before-Assembly Training:

The system supports disassembly-before-assembly exercises, reinforcing practical skills and boosting learners’ confidence in real-world applications.

Benefits for Students:

Engagement with Realistic Simulations:

Students interact with 3D models of lathes, tools, and components to simulate actual machining processes. This interactive environment aids in mastering turning operations and builds essential skills without the risk of physical injury.Master Key Machining Concepts:

The system covers essential topics like tool handling, fixture setup, gauge use, and lathe operations. Learners can explore horizontal and vertical lathe components, ensuring a comprehensive understanding of turning machinery.Assessment and Skill Tracking:

The system includes evaluations to test skills in creating specific parts, such as horizontal shafts, conical parts, and threaded components. It helps students develop precision and accuracy in manufacturing.Safe, Risk-Free Learning Environment:

Students can practice and make mistakes within the safety of the virtual world, fostering confidence and preventing costly real-world errors.

Benefits for Educators:

Enhanced Teaching with Realistic Simulations:

Educators can use the system to explain complex turning operations clearly and comprehensively. The immersive, step-by-step process makes teaching easier and more engaging.Comprehensive Skill Assessment:

Educators can assess students’ performance through detailed data reports. This helps identify strengths and weaknesses, allowing for targeted interventions to improve learning outcomes.Flexible Teaching Tool:

With the ability to access the system on both PCs and VR headsets, instructors can teach in various settings and accommodate different learning preferences.Improved Classroom Efficiency:

The system’s modular structure and detailed instructions mean that educators can guide multiple students through the training simultaneously, enhancing classroom efficiency and collaborative learning.Safety and Risk Reduction:

By simulating real-world risks, educators can ensure students understand safety protocols without exposing them to potential harm. The system includes virtual protection against common machine accidents.

Conclusion:

The Turning Technology Virtual Simulation Teaching System is an essential tool for any educational institution or training center focused on machining and turning operations. It offers a safe, engaging, and highly effective way to train students, build their practical skills, and ensure they’re prepared for real-world challenges in the manufacturing industry. Whether used for individual practice or structured assessments, this system delivers a comprehensive learning experience that can be accessed at any time, making it an invaluable resource for modern vocational education.

Specifications:

- 3D Virtual Simulation Environment: Interactive, real-time models

- Cross-Platform Accessibility: Available for PC and VR headsets

- Modular Training Structure: Separate modules for tools, fixtures, and lathes

- Safety and Risk Compliance: Virtual simulations of real-world risks

- Customizable Assessments: Test proficiency in horizontal shafts, conical parts, threaded components, and discs

- Data Feedback: Detailed performance reports to guide progress

This innovative tool is a game-changer for turning training, providing both students and instructors with the tools needed to succeed in the rapidly evolving manufacturing industry.