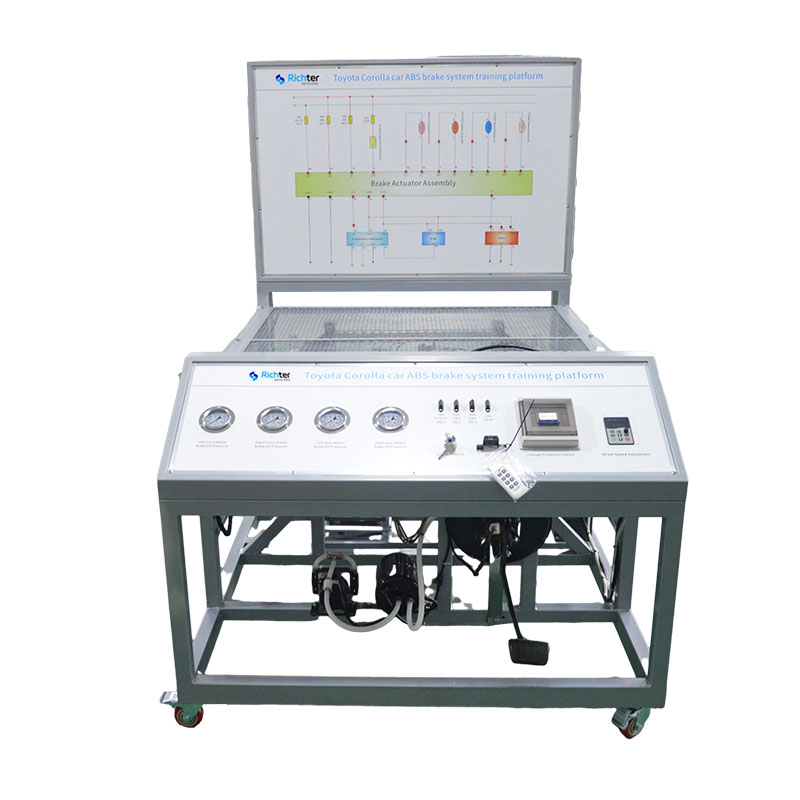

Learn hands-on with a fully automotive ABS braking system trainer. Explore emergency braking, diagnostics, and real-time data monitoring to master vehicle braking technology.

Key Features and Functional Benefits

Real Vehicle ABS System Simulation

At the core of the trainer is a real-world ABS brake system, accurately replicating the structure and operation of the vehicle’s braking components. This allows students to familiarize themselves with every part of the ABS system, enhancing their practical understanding.Emergency Braking Demonstration

Powered by an asynchronous motor, the ABS braking system trainer simulates the dynamic braking process of a vehicle. In an emergency braking scenario, students will observe the real-time activation of the ABS system, as both the front and rear brake discs rotate slightly, while the brake pedal exhibits continuous springing—providing a tactile, realistic learning experience.Comprehensive Circuit and Hydraulic Diagrams

The platform’s panel features color-coded UV flat-plate spray circuit and hydraulic pipeline diagrams. These diagrams enable students to visually connect the theoretical aspects of the ABS system with its real-world counterparts, facilitating a clearer understanding of the system’s operation.Direct Electrical Signal Monitoring

The training bench comes equipped with a detection terminal, allowing students to directly monitor electrical signals such as resistance, voltage, current, frequency, and more. This feature ensures students gain hands-on experience with the electrical side of ABS systems, which is crucial for diagnosing issues.Real-Time Hydraulic Pressure Monitoring

Equipped with a pressure gauge, the trainer provides real-time feedback on the hydraulic changes within the brake master cylinder and four brake slave cylinders. This feature supports the understanding of hydraulic forces and their role in braking performance.Fault Diagnosis and ECU Functionality

The panel includes a fault indicator and diagnosis seat, which connects to a vehicle diagnostic tool (such as a special or general vehicle decoder). Students can perform self-diagnostic functions, including ECU code queries, fault code reading and clearing, actuator testing, data flow analysis, and waveform analysis. This hands-on diagnostic tool enhances students’ troubleshooting skills and understanding of ABS/EBD electronic control systems.

Technical Specifications

- Overall Dimensions: 1500×1000×1700mm (L×W×H)

- External Power Supply: AC 220V ±10%, 50Hz

- Operating Voltage: DC 12V

- Operating Temperature: -40℃ ~ +50℃

- Brake Slave Cylinder Pressure Gauge: 0-100kg/psi

- Asynchronous Motor:

- Voltage: AC 220V, 50Hz

- Current: 11.8A / 6.8A

- Power: 3KW

- Rotating Speed: 1420r/min

- Vacuum Pump:

- Voltage: AC 220V, 50Hz

- Power: 370W

- Suction Rate: 48L/min

- Maximum Pressure: 6.7×10⁻²Pa

- Rotating Speed: 1400r/min

- Inlet Aperture: Ø8

- Oil Consumption: 1L

- Noise Level: ≤68dB

- Steel Tubing: 60×40×3mm

- Caster Wheels: 100×50mm

- Panel Cabinet: 1.5mm cold-plate stamped and formed

Benefits for Students

- Hands-on Experience with a fully functional ABS system, allowing students to explore both the mechanical and electronic aspects of vehicle braking.

- Practical Understanding of emergency braking scenarios, giving students the chance to directly experience ABS activation during simulated braking events.

- Troubleshooting Skills developed through direct interaction with system components, sensor testing, and fault simulation.

- Real-Time Data Monitoring allows students to track live system parameters and perform diagnostics—enhancing their technical expertise in automotive electronics.

Benefits for Instructors

- Real Vehicle Components ensure that the trainer replicates real-world systems for authentic learning experiences.

- Comprehensive Fault Simulation enables instructors to demonstrate common ABS system failures and guide students through the diagnostic and repair processes.

- Interactive Learning facilitated by intuitive circuit diagrams and monitoring equipment for easy comprehension of complex systems.

- Portability and Durability ensure the trainer can be easily moved and used in various training environments, thanks to a robust frame with caster wheels.

Perfect for Educational Institutions

This ABS Braking System Trainer is an ideal solution for universities, vocational schools, and automotive training centers. It enables instructors to provide cutting-edge, hands-on education to students, fostering a deep understanding of automotive systems. By using real-world parts and advanced simulation capabilities, students are better prepared for real-world automotive repair and maintenance challenges.

Optional Equipment (Sold Separately)

- Diagnostic scan tool TXB BIKE TEXA

- Diagnostic oscilloscope TEXA Uniprobe

- Diagnostic oscilloscope Automotive Diagnostics Kit ADK5004D TiePie

- Diagnostic oscilloscope Foxwell Oscilloscope OS100

Contact Us Today

For more information on the Automotive ABS Braking System Trainer, or to inquire about our full range of automotive training equipment, visit our website at Richter – World Leading Automotive and Electric Vehicle Training Solutions. Let Richter help you enhance your students’ technical skills with the best automotive training equipment available!