As a global leader in automotive and electric vehicle training solutions, Richter is dedicated to equipping educational institutions and repair companies with innovative, hands-on training equipment. Our Electric Vehicle Original High-Voltage Control Box Assembly, Disassembly, and Testing System is designed to provide comprehensive insights into the critical technology behind new energy vehicles, ensuring that students gain practical skills that translate directly into industry competence.

Product Overview

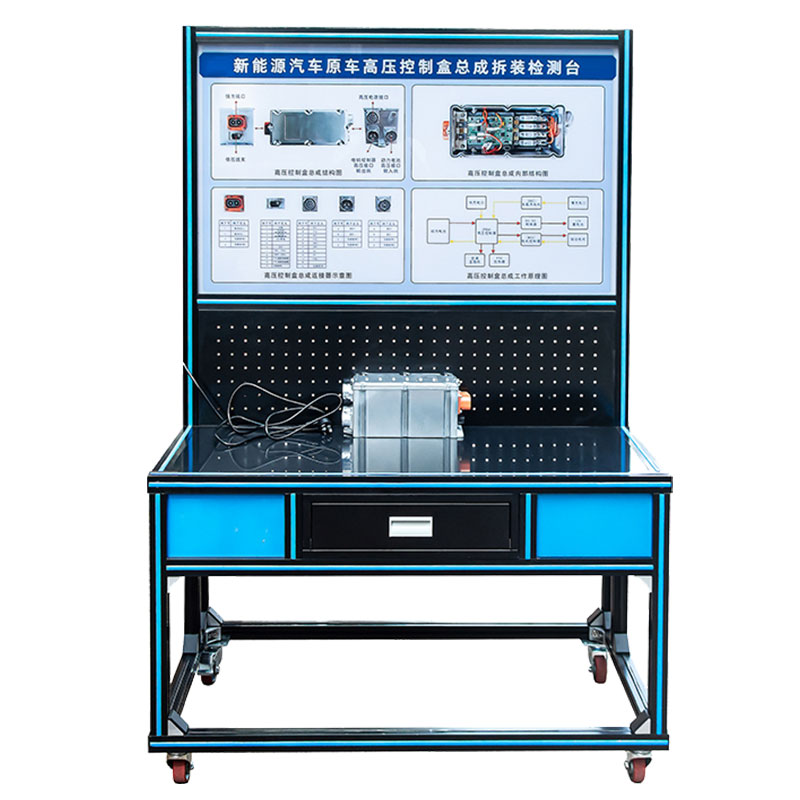

Constructed with either an aluminum alloy frame or a high-strength, nationally certified welded steel structure, our system is engineered for durability and safety. The spray-treated surface can support worktables weighing between 300–400 kg, ensuring excellent load-bearing and stability. The mobile design features two fixed casters and two universal casters with locking devices, allowing for easy repositioning and secure placement in various training environments.

Key Features & Training Objectives

In-Depth Understanding of High-Voltage Control Boxes

- Working Principles: Gain firsthand experience by disassembling and reassembling the high-voltage control box, allowing students to directly observe its operating mechanisms.

- Structural Analysis: Detailed schematics and clearly labeled wiring diagrams help learners understand the internal structure and design rationale.

- Comparative Insights: Analyze the characteristics of different high-voltage control boxes to deepen knowledge of the technological variations in new energy vehicle systems.

Hands-On Practical Skills

- Assembly & Disassembly: Intensive training sessions focus on developing the skills needed for the safe and efficient disassembly and reassembly of high-voltage control boxes.

- Component Testing & Measurement: Equipped with essential diagnostic tools—including a multimeter, a comprehensive wrench set, rubber and round-headed hammers, a set of knockable screwdrivers, and a scraper—the system enables precise measurement and fault detection.

- Fault Simulation & Analysis: The system’s design allows educators to simulate common faults, enabling students to learn troubleshooting techniques and interpret fault codes accurately.

Comprehensive Toolset and Teaching Support

To ensure a complete learning experience, the system comes with:

- Tool Configuration: A full set of diagnostic and assembly tools, including a 23-piece plum wrench set and an 8-4T wrench set, among others.

- Repair Manual: A detailed High Voltage Controller Repair Manual guides the training process, ensuring that every step is clear and actionable.

- Complete Product Package: Includes one motor controller assembly, one mobile support frame, a matching toolset, detailed schematics, and an instruction manual.

Specifications

- Dimensions: Minimum of 1200 × 700 × 1800 mm (L×W×H)

- Construction: Aluminum alloy/high-strength welded steel frame

- Load Capacity: Supports worktable loads of 300–400 kg

- Mobility: Features two fixed casters and two lockable universal casters for ease of movement and secure positioning

Value for Students and Instructors

For Students

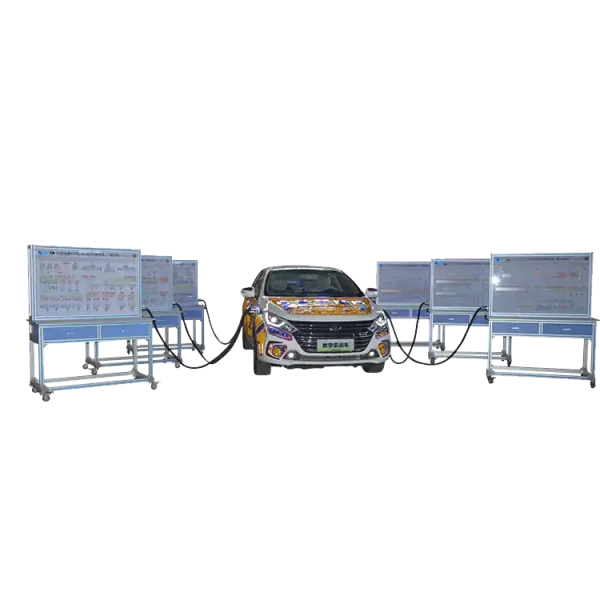

- Practical Experience: Engage with real OEM-level components, moving beyond theoretical knowledge to hands-on practice.

- Skill Enhancement: Master essential techniques in assembly, disassembly, and diagnostic testing, building a robust foundation for a career in new energy vehicle maintenance.

- Career Advantage: Acquire specialized skills that are highly valued in the growing fields of electric vehicle and hybrid system repair.

For Instructors and Training Centers

- Enhanced Teaching Efficiency: Demonstrate complex concepts through direct interaction with authentic automotive components.

- Safety and Reliability: The enclosed design with protected wiring and removable panels ensures a safe training environment while allowing easy access for instructional purposes.

- Flexibility and Ease-of-Use: The plug-and-play design minimizes setup time, enabling rapid transition between training sessions and maximizing classroom efficiency.

Richter’s Electric Vehicle Original High-Voltage Control Box Assembly, Disassembly, and Testing System not only provides a complete training solution but also empowers the next generation of automotive professionals with the skills needed to excel in a rapidly evolving industry.