Part 1: Product Introduction

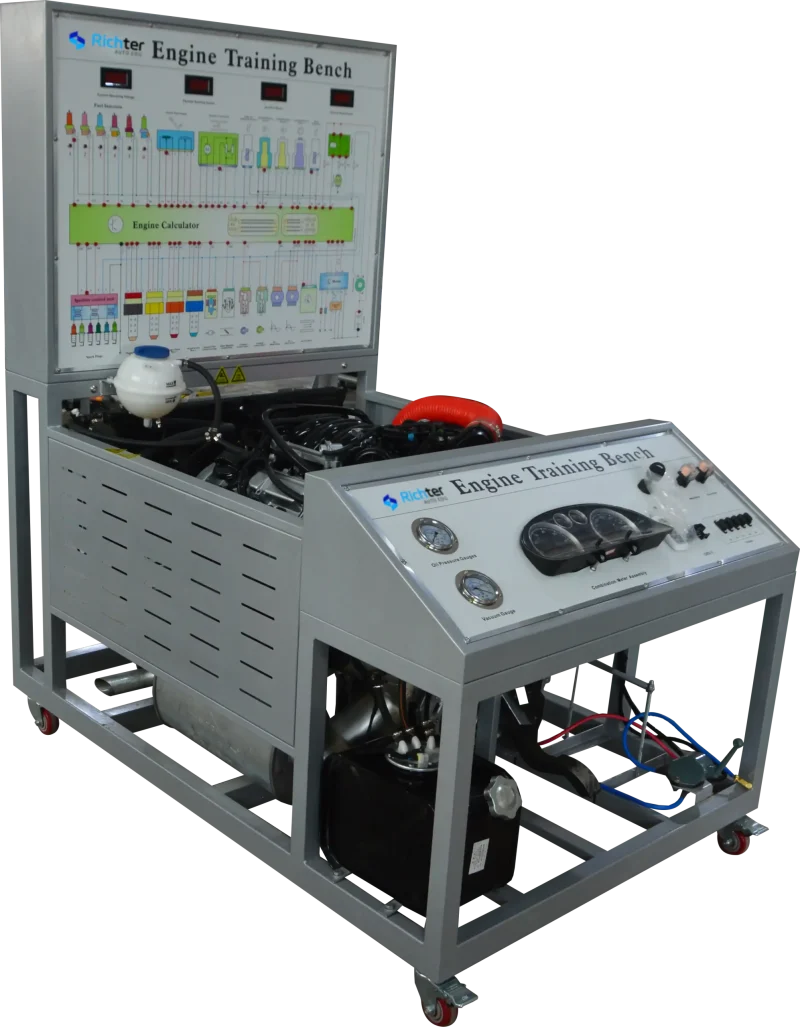

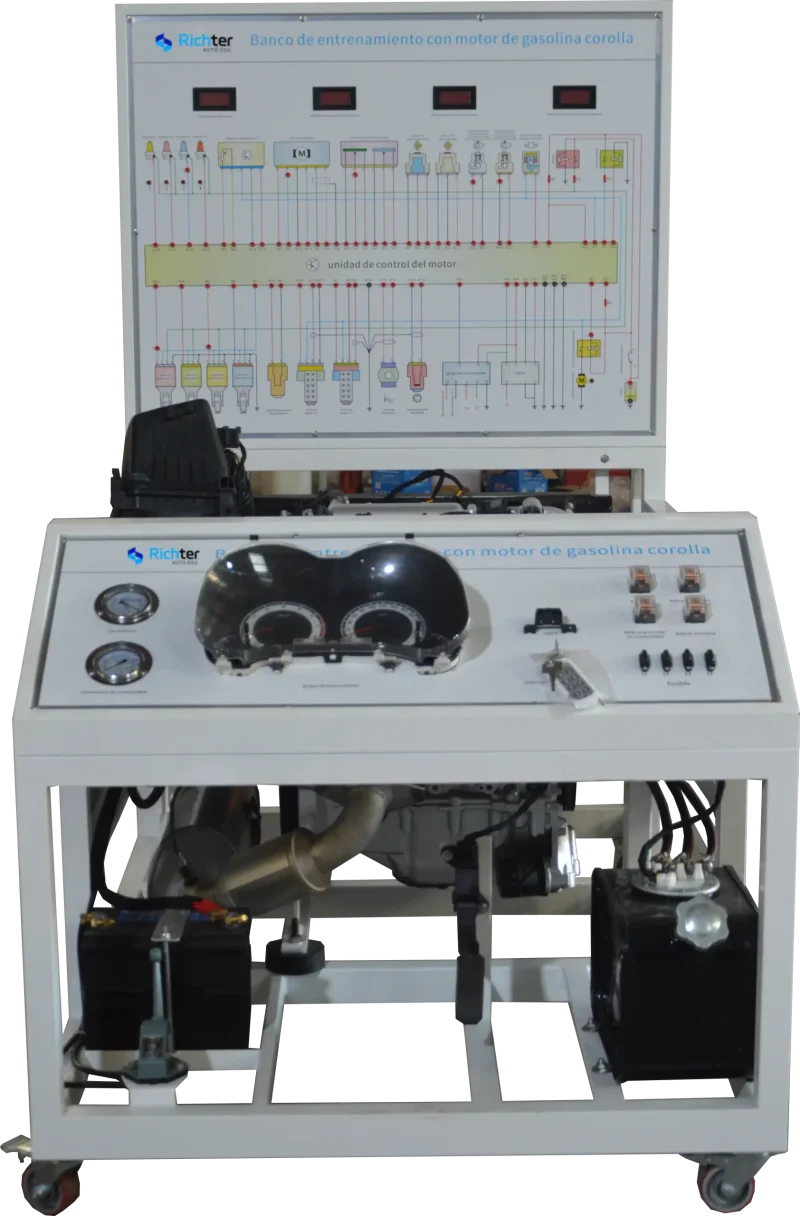

The Gasoline Engine Trainer by Richter is a state-of-the-art educational tool designed for hands-on learning in automotive training. This comprehensive training system features a fully operational electric-controlled gasoline engine, along with a test control panel and detailed diagnostic capabilities. It is ideal for vocational schools, technical colleges, and automotive training centers, providing students with an in-depth understanding of engine mechanics, diagnostics, and repair processes.

The trainer is composed of two main parts:

- Fixed Frame: The electric-controlled gasoline engine assembly with its running accessories.

- Test Control Panel Frame: This panel allows for real-time monitoring and adjustments of the engine during various operational tests.

Students will gain invaluable practical experience by operating the engine through starting, accelerating, decelerating, and other essential engine functions. The design offers a clear visual comparison between actual engine operations and theoretical circuit diagrams, enhancing students’ understanding of engine systems.

Part 2: Functional Features

Realistic Engine Operations:

- The trainer features a genuine electric-controlled gasoline engine capable of performing key operations such as starting, acceleration, and deceleration. This ensures a realistic training environment for students to explore engine mechanics.

Integrated Training Bench:

- The engine assembly and running accessories are mounted on a robust fixed frame, while the test control panel allows students to interact directly with engine components and monitor parameters.

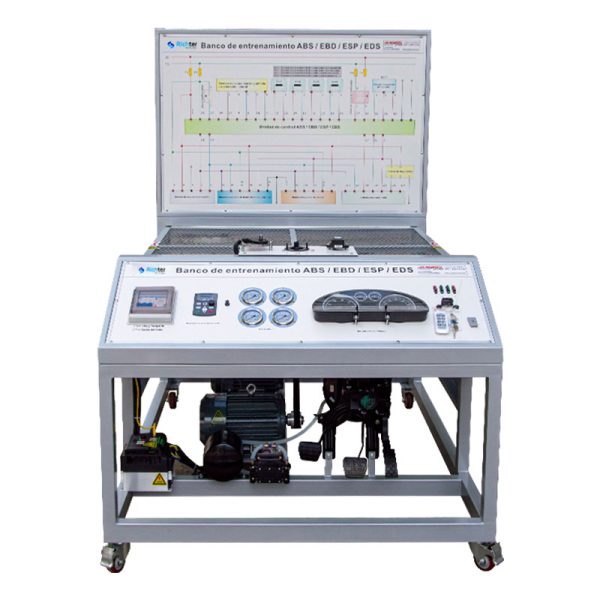

Color-Coded Circuit Diagram:

- The UV flat spray-printed circuit diagram on the training panel allows students to easily compare the actual engine layout with the control system’s wiring. This feature provides a hands-on approach to understanding engine circuits and their working principles.

Detection Terminals:

- With built-in detection terminals, students can measure electrical signals like resistance, voltage, current, and frequency from various sensors, actuators, and the engine control unit. This allows for real-time diagnostics and troubleshooting practice.

Automotive Instrumentation:

- The trainer includes instruments such as fuel pressure gauges and vacuum pressure gauges, displaying real-time engine parameters like speed, fuel pressure, and other key metrics, simulating actual engine performance.

Diagnostic Seat:

- The diagnostic seat enables connection to specialized or universal automotive diagnostic tools, allowing for fault code reading, clearing, and live data stream monitoring. This feature mimics real-world engine control diagnostics, providing students with the tools necessary for professional automotive troubleshooting.

Durable and Mobile Frame:

- The base is welded from steel tubes (40x60x3mm) and features protective circular bars on the front and sides. Coated with a high-quality spray process, it is equipped with durable self-locking casters, ensuring easy mobility and secure positioning within the training environment.

Part 3: Technical Specifications

- Power Supply: DC 12V (Battery: 60AH 12V)

- Fuel: As per engine model

- Fuel Tank Capacity: 10L

- Operating Temperature Range: -40℃ to +50℃

- Steel Tube Dimensions: 40603mm

- Panel Cabinet Material: 1.5mm cold-rolled steel, stamped and formed

- Mobile Casters: 120*80mm

- Dimensions: 1500mm (L) x 1000mm (W) x 1700mm (H)

Why Choose the Gasoline Engine Trainer?

For Students:

- Experience a real electric-controlled gasoline engine with practical demonstrations of key engine functions.

- Access detection terminals for hands-on diagnostics of engine sensors, actuators, and control units.

- Engage with live data monitoring, fault code reading, and diagnostic troubleshooting through integrated tools.

- Learn to interpret real-world circuit diagrams and operate an engine through a comprehensive, easy-to-use control panel.

For Instructors:

- Teach engine operation, diagnostics, and repair with a fully functional, real-world engine system.

- Use the UV-printed circuit diagram to show the direct connection between theory and practice.

- Simulate faults and train students to diagnose and resolve issues, mirroring the conditions they will face in the automotive industry.

- Enhance collaborative learning in a classroom setting with the mobile and durable design, ideal for easy transport between training sessions.

Optional Equipment (Sold Separately):

- Diagnostic Scan Tool: TXB BIKE TEXA

- Diagnostic Oscilloscope: TEXA Uniprobe

- Automotive Diagnostic Kit: ADK5004D TiePie

- Oscilloscope: Foxwell Oscilloscope OS100

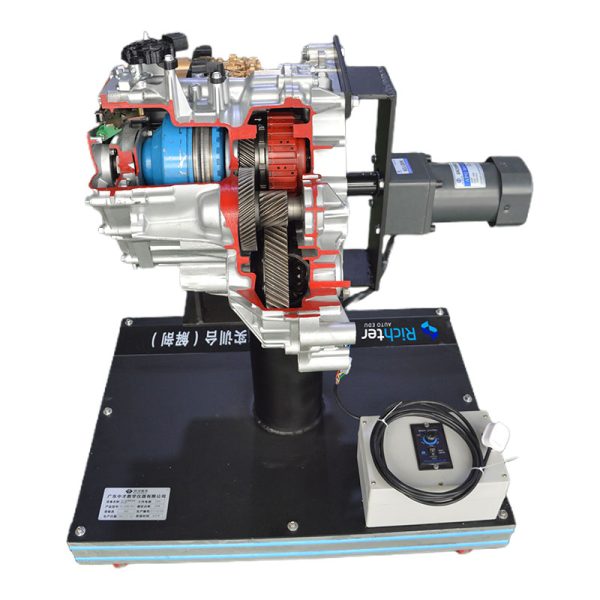

About Richter: Richter is a leading manufacturer of automotive and electric vehicle training solutions. With our focus on innovation and education, we collaborate with top automotive manufacturers and educational institutions worldwide to deliver advanced training tools. Our products, such as Automotive Trainers, Electric Vehicle and Hybrid Trainers, and Automotive Simulation Training Software, empower students, technicians, and automotive professionals to enhance their skills and stay ahead in an ever-evolving industry.

Contact Us: If you are interested in the Gasoline Engine Trainer or any of our other automotive training equipment, please visit our website or contact us directly for more information. We are here to support your educational and training needs!