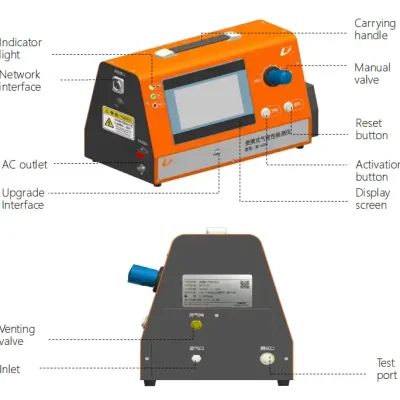

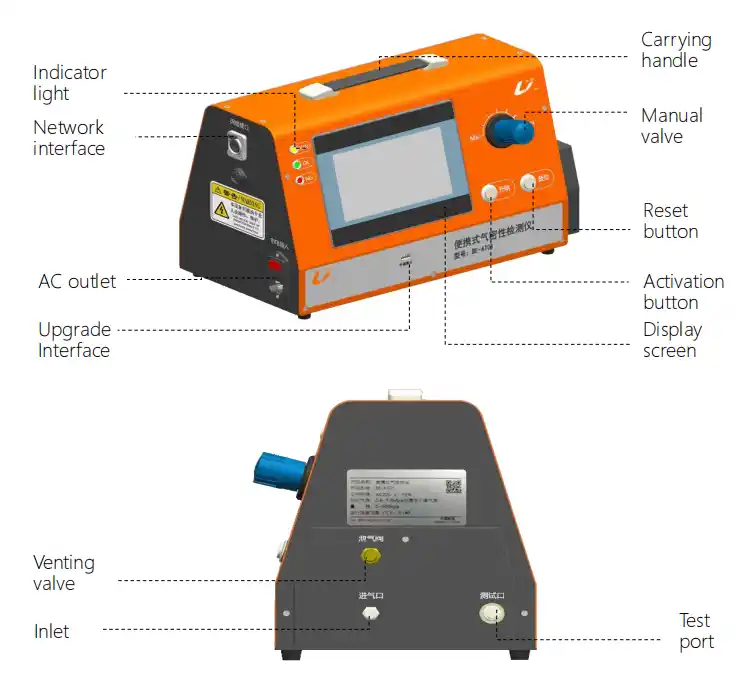

The Portable Air Tightness Tester (BE-AT01) is a state-of-the-art device designed for precise and efficient air-tightness testing in various applications, particularly in the automotive and electric vehicle sectors. This instrument utilizes the differential pressure test method, ensuring accurate and non-destructive testing of product integrity.

Key Features:

- Differential Pressure Test Method: Ensures high accuracy in detecting leaks.

- Versatile Pressure Ranges: Supports both low-pressure (0-20KPa) and high-pressure (20-500KPa) testing modes.

- User-Friendly Interface: Default 7 parameter groups for easy setup and operation.

- Portable Design: Compact and lightweight, making it suitable for on-site testing.

- System Upgrades: USB port available for system updates and enhancements.

Technical Specifications:

| Indicator Project | Technical Parameters |

|---|---|

| Detection Method | Differential Pressure Test Method |

| Air Supply | External Air Supply |

| Supply Voltage | AC 176~264Vac, frequency 50/60Hz |

| Power Wastage | 30W |

| Low-Pressure Mode | Test Pressure Range: 0-20KPa |

| Differential Pressure Sensor Range: ±2000 Pa | |

| Differential Pressure Sensor Accuracy: ±0.5%FS | |

| Test Accuracy: ±1%FS | |

| High-Pressure Mode | Test Pressure Range: 20~500KPa |

| Differential Pressure Sensor Range: ±2000 Pa | |

| Differential Pressure Sensor Accuracy: ±0.5%FS | |

| Test Accuracy: ±2%FS | |

| Parameters | Default 7 groups |

| USB Port | System Upgrades |

| Connection Piping | Outer diameter 6mm PU tube (nylon tube) |

| Test Gas Source | Clean and dry compressed air source of 0.4MPa ~ 10MPa |

| Ambient Temperature, Humidity | Temperature 5~40°C, 80% HR or less, no condensation |

| Dimensions | 425210260 mm |

| Weight | 9 KG |

Applications:

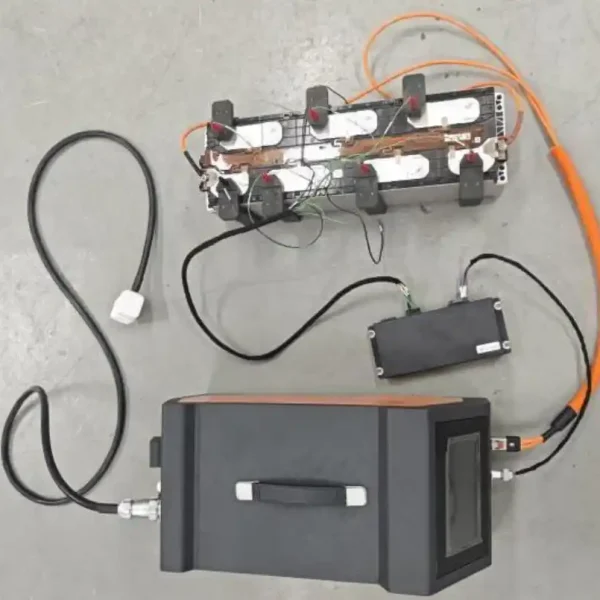

- Automotive Industry: Ideal for testing the air-tightness of various automotive components.

- Electric Vehicles: Suitable for ensuring the integrity of EV battery enclosures and other critical components.

- Educational Institutions: Useful for training purposes in universities and vocational schools.

- Manufacturing: Applicable in quality control processes in manufacturing units.