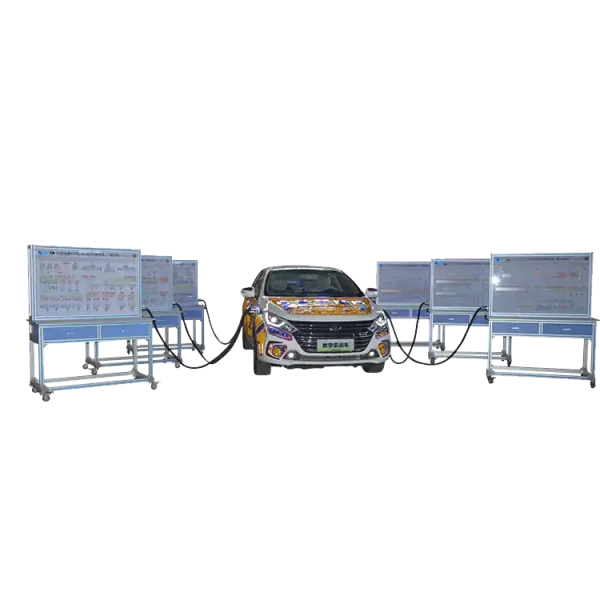

Power Battery Assembly and Testing Technology Training System – Intelligent teaching platform with MiniPC and 43-inch HD multimedia display. Features smart self-test, graphical interface for real-time monitoring of battery pack total voltage, average temperature, individual cell voltage, SOC, and fault diagnosis via CANbus.

Key Features and Technical Highlights

Smart Self-Test and Dynamic Evaluation

Upon startup, the system automatically enters a self-test mode, evaluating critical communication modules (such as M1203 and CAN interfaces). Abnormal statuses are flagged in red, while normal conditions are highlighted in green. Once all checks are confirmed, the system is ready for operation—ensuring each training session is both safe and reliable.Graphical Display and Real-Time Monitoring

The training mode visually presents vital battery parameters including total pack voltage, average temperature, individual cell voltages (with maximum and minimum values), individual cell temperatures, discharge/charge current, and SOC. By clicking the discharge or charge button, users can view additional details like discharge current, estimated discharge time, charging gun status, charging mode (CC/CP), charging current, and remaining charge time.Comprehensive Fault Diagnosis and Relay Detection

Utilizing CANbus communication, the system offers robust contactor detection, monitoring key components such as the master positive relay, master negative relay, precharge relay, discharge relay, and both slow and fast charge relays in real time. This feature enables realistic fault simulation and immediate data feedback for enhanced diagnostic training.Integrated Multifunctional Training Modes

Designed with three main functions—Theory, Training, and Debugging—the system meets diverse educational needs. It allows students to understand battery assembly, calibration, and testing comprehensively while enabling instructors to simulate faults and guide troubleshooting processes effectively.

Product Specifications

- Training Bench Dimensions: 1800mm × 900mm × 550mm (L × W × H)

- Compatible Battery Systems: Supports major battery systems, including BYD and BAIC.

- Display System: 43-inch HD multimedia screen for clear, dynamic data visualization.

- Control Platform: Interactive human-machine interface powered by a MiniPC.

Value for Students and Training Institutions

For Students:

- Hands-On Experience: Gain practical insights by monitoring real-time battery data during assembly, calibration, and fault diagnosis.

- Data Analysis: The intuitive graphical interface simplifies complex battery parameters, enhancing analytical and troubleshooting skills.

- Integrated Learning: Seamlessly combines theory, practical training, and debugging for a comprehensive learning experience.

For Instructors and Institutions:

- Enhanced Teaching Tools: The clearly labeled control panel and wiring diagrams streamline complex technical concepts, making them accessible and easy to understand.

- Efficient Monitoring: Real-time data feedback and fault simulation capabilities allow instructors to quickly identify issues and adjust training modules.

- Robust and Safe Design: The system’s secure internal wiring and detachable panels provide a safe environment while allowing convenient access for maintenance and upgrades.

- Collaborative Learning: Its durable construction and mobility support multiple simultaneous users, fostering teamwork and interactive learning.

About Richter

Richter is renowned worldwide for its innovative training solutions in automotive and electric vehicle technology. In close collaboration with leading automotive manufacturers and educational institutions, we ensure our products are at the forefront of industry trends. Our mission is to empower automotive professionals and students through cutting-edge training equipment and simulation software.

Our main product categories include:

- Automotive Trainers

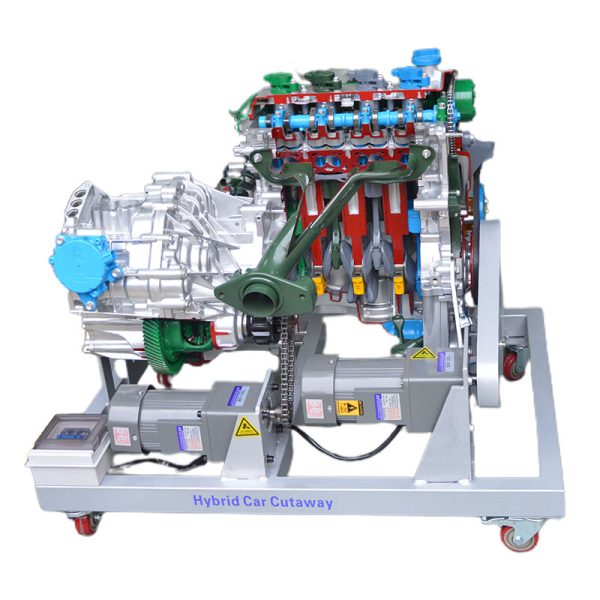

- Electric Vehicle and Hybrid Trainers

- Automotive Simulation Training Software

- Smart Manufacturing Software

- Automotive Training Tools

- Training Services

Each product is meticulously engineered to provide a realistic training environment that enhances practical skills and technical proficiency.

Conclusion

The Power Battery Assembly and Testing Technology Training System is not just an educational tool—it’s a bridge between theoretical learning and real-world practice. Perfect for electric vehicle battery system training, it equips both students and instructors with the necessary tools to master modern battery technology. Discover how Richter’s innovative solutions can elevate your training program. Contact us today to learn more about enhancing your educational offerings with our advanced teaching systems.