Electric vehicles (EVs) are rapidly transforming the automotive world. But as these cars grow more complex, diagnosing their issues becomes tougher. That’s where electric vehicle diagnostic simulation software comes in. This software brings the power of simulation into EV training and repair, helping technicians and students master EV systems without the risks or costs of handling real vehicles.

In this article, we’ll dive into the key benefits, real-world uses, and how Richter’s advanced training solutions fit perfectly into this evolving landscape. Whether you’re an educator, repair shop owner, or EV enthusiast, understanding these tools will save you time, money, and headaches.

Índice

What Is Electric Vehicle Diagnostic Simulation Software?

In simple terms, this software replicates the behavior of EV systems on a computer or virtual platform. It mimics everything—from battery management and motor control to high-voltage circuits—allowing users to diagnose faults, test repair procedures, and practice maintenance in a risk-free environment.

This technology fills the gap between textbook knowledge and hands-on experience. It’s widely used in vocational schools, automotive training centers, and even by manufacturers for pre-service training.

Why Electric Vehicle Diagnostic Simulation Software Matters for EV Training

Electric vehicles aren’t just cars; they’re rolling computers. With high-voltage batteries, sophisticated control units, and complex CAN-BUS communication, diagnosing problems requires both deep knowledge and practical skills.

Here’s where simulation shines:

- Risk-Free Learning: Trainees can safely explore faults without damaging expensive equipment or risking personal injury from high-voltage components.

- Cost Savings: Real EV parts are costly to replace. Simulators reduce wear and tear, extending the lifespan of physical trainers.

- Flexible Training Scenarios: From simple battery faults to complex drive motor issues, software enables diverse scenarios that might not occur often in the real world.

- Remote and Repeatable: Students can access simulations anywhere, anytime, making training scalable and consistent.

Popular Electric Vehicle diagnostic Simulation Software & Their Strengths

| Software Name | Use Cases | Caraterísticas principais | Fonte |

|---|---|---|---|

| SimEV | EV Powertrain Design | Plug-and-play vehicle simulation, multi-driving cycles | dorle |

| EV Technician | Technician Training | Virtual lab for diagnostics, circuit simulation | evtech |

| SANLAB EV Simulator | Maintenance & Repair Training | VR-based fault diagnosis, remote learning | sanlablearnin |

| YESA-EVSIM | Educational Diagnosis | Multi-mode drive simulation, fault diagnostics | yes01 |

These tools cover a wide spectrum of EV training needs—from engineering and design to technician skill-building. And the good news? Richter complements this with practical hands-on trainers and software that integrate perfectly into such learning systems.

Real-World Example: Battery Health Diagnosis

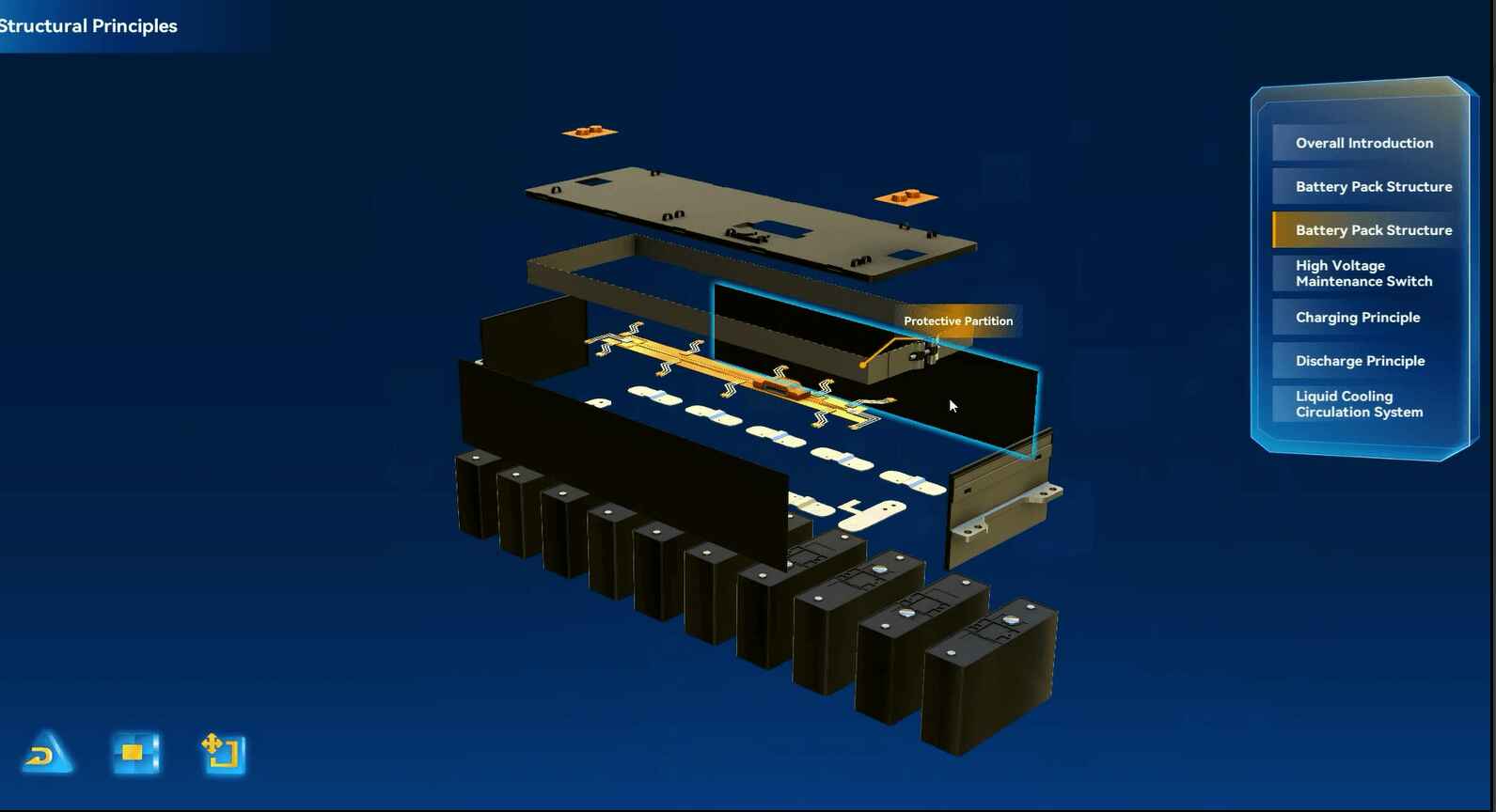

One key challenge with EVs is maintaining battery health. A recent study showed how simulation combined with real diagnostic tools (like Bosch KTS) allows quick assessment of battery modules after years of use and thousands of kilometers.

By simulating full battery discharge and measuring module voltages in the software, technicians can predict remaining battery life accurately—cutting down costly trial-and-error in the field. This approach also fits well with Richter’s Sistema de formação em tecnologia de montagem e teste de baterias eléctricas, which provides both physical and simulated experiences to learners.

MATLAB/Simulink: The Backbone of EV System Simulation

In research and industry, MATLAB/Simulink has become the go-to environment for EV simulation. It allows engineers to build detailed models of motors, batteries, controllers, and the entire drivetrain. These models help validate performance before real-world deployment.

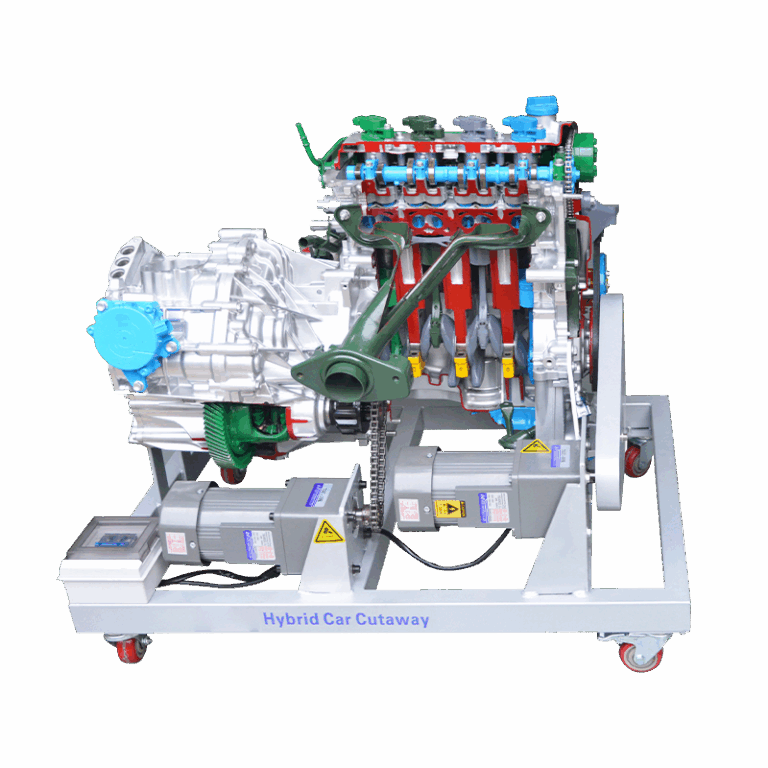

For training, MATLAB simulations are powerful tools to help students visualize the intricate dynamics inside an EV, making abstract concepts tangible. Richter offers Formadores de sistemas de propulsão de veículos eléctricos that bridge software models with real hardware, providing a complete learning loop.

How Richter Fits into This Landscape

At Richter, we understand that true expertise demands more than theory. That’s why our portfolio includes both simulation software and physical trainers designed specifically for electric and hybrid vehicles. Here are some highlights:

- Software de formação para diagnóstico de avarias em veículos eléctricos: Enables users to simulate and troubleshoot real EV faults in a controlled environment.

- Software de formação para desmontagem e montagem de baterias de veículos eléctricos: Hands-on battery skills with virtual support.

- Sistema de formação em diagnóstico de avarias do quadro elétrico do veículo elétrico: Combines hardware and software for full-system fault learning.

Our integrated approach blends virtual and physical training, which boosts skill retention and reduces training costs. We help training centers deliver realistic EV repair scenarios safely and efficiently.

Cost-Saving Scenarios for Training Centers and Workshops

Here’s the bottom line: investing in simulation software and trainers from Richter pays off.

| Ponto de dor | Traditional Approach Cost | Richter Simulation Approach | Savings/Benefits |

|---|---|---|---|

| Parts replacement for hands-on labs | High – costly EV components | Low – simulated faults reduce wear | Save up to 40% on parts replacement |

| Training downtime due to failures | High – risk of damaging real vehicles | Low – virtual faults avoid damage | Reduce downtime by 30% |

| Instructor workload | High – needs close supervision | Moderate – software allows self-paced learning | Free up instructor time by 25% |

| Student accessibility | Limited to lab hours | Flexible remote or onsite simulation access | Increase training throughput by 20% |

Common Industry Terms (Industry Black Talk)

- CAN-BUS Diagnostics: The backbone communication protocol in EVs; software simulates CAN signals for fault tracing.

- BMS (Battery Management System): Critical for monitoring battery health; simulations allow testing BMS responses to faults.

- Drive Motor Calibration: Adjusting motor controls for performance; simulation software offers fine-tuning without risk.

- High-Voltage Safety Protocols: Simulation trains users in safe handling of dangerous circuits, preventing real-world accidents.

- Fault Injection: Purposefully introducing errors to test diagnostic skills—easily done in software before touching real EVs.

These terms come alive with Richter’s trainers and software, equipping your team to hit the ground running.

Looking Ahead: The Future of Electric Vehicle Diagnostic Simulation software

The next step? Integrating AI and machine learning into simulation tools to predict faults before they happen, personalize training paths, and even assist remote technicians in real-time.

Richter is investing in these innovations. Our software updates and training modules evolve alongside the industry, making sure your team always stays ahead.

Summary: Why You Should Care

If you’re involved in EV education or repair, electric vehicle diagnostic simulation software isn’t just a nice-to-have—it’s a must-have. It saves money, reduces risk, and prepares technicians for the complex, fast-changing EV world.

By combining software simulation with hands-on equipment like Richter’s, you create a comprehensive, future-proof training ecosystem. This approach drives better results, faster troubleshooting, and higher customer satisfaction.

Check out Richter’s offerings today and give your training program the boost it deserves.