If you’re diving into automotive repair training, one thing quickly becomes clear: having the right tools isn’t just nice to have—it’s a must. When teaching future mechanics, hands-on experience with real tools shapes skill and confidence. But how do you know which tools actually matter most for training? And how can training programs keep up with today’s complex vehicles?

At Richter, we get it. We’ve seen first-hand how the right training tools can transform classrooms and workshops. So let’s break down why automotive repair tools are critical for hands-on learning, what tools should be in your toolkit, and how smart investments can boost both teaching outcomes and students’ career paths.

Índice

1. Automotive Training Tools Must Match Training Goals and Course Modules

One major mistake some training centers make is offering a generic toolset that doesn’t align with their curriculum. Automotive repair isn’t one-size-fits-all; whether students are learning about brake systems, electrical wiring, or engine mechanics, the tools need to fit the topic perfectly.

For example, look at Austin Community College’s required tool lists for specific courses:

| Course | Key Tools and Their Uses |

|---|---|

| Automotive Electrical Systems | Digital multimeters, battery terminal cleaners for diagnostics |

| HVAC Repair | Digital thermometers, UV leak detection lamps, refrigerant adapters |

| Brake System Maintenance | Caliper piston compressors, drum spring removal tools |

| Transmission & Drivetrain | Clutch alignment tools, flywheel wrenches, seal pullers |

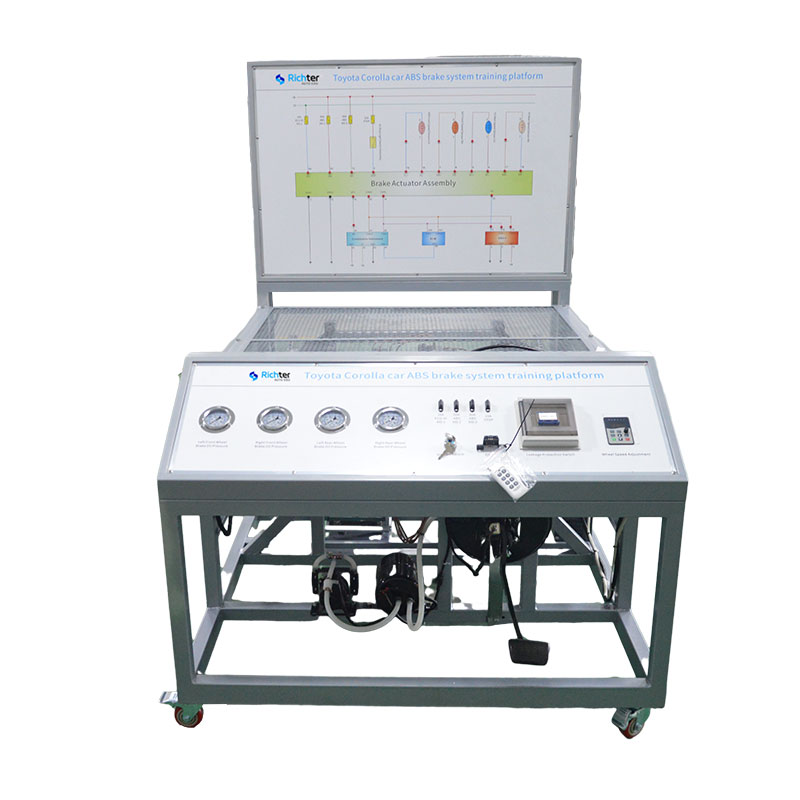

You can see how every tool is targeted to a system, improving training focus and reducing confusion. Richter’s lineup reflects this tailored approach—our Formador de sistemas de travagem ABS para automóveis lets students get hands-on with brake tech using industry-grade parts and automotive repair tools that mirror real shop conditions.

2. Building a Professional Toolset: What Every Tech Needs

The pro world breaks down tools into categories for practical reasons—and training programs should, too. Here’s a simple breakdown from Universal Technical Institute’s (UTI) expert guidelines:

| Tool Category | Examples | Why They Matter |

|---|---|---|

| Core Hand Tools | Ratchets, wrenches, screwdrivers, pliers | Foundation of everyday repairs |

| Torque Tools | Torque wrenches, digital torque analyzers | Ensure correct tightness, prevent damage |

| Power Tools | Electric impact wrenches, grinders | Speed up repetitive tasks |

| Diagnostic Tools | Scan tools, multimeters | Pinpoint electronic and sensor faults |

| Storage & Organization | Tool carts, cabinets | Keeps workspace efficient and tools protected |

UTI even partners with Snap-on to offer students discounted professional-grade tool kits—showing how critical these sets are for launching careers. Richter helps bridge this gap by providing comprehensive tool car sets packed with everything from hand tools to electrical testers, designed specifically for classroom or shop use.

3. Why Virtual Reality Training Can’t Fully Replace Real Tools (Yet)

Virtual reality (VR) is buzzing as a training method, especially for complex systems like engines. South China University of Technology developed a VR system simulating engine assembly and disassembly that’s flexible and cost-effective. It lets students practice repeatedly without wasting real parts or needing large spaces.

| Training Method | Pros | Cons |

|---|---|---|

| VR Training | Cost-effective, reusable, safe | Lacks tactile feedback and tool handling realism |

| Hands-On Training | Realistic experience, builds muscle memory | High cost, requires physical space and maintenance |

Still, VR can’t replace the feel of a wrench tightening a bolt or the resistance when testing a brake caliper. For that hands-on grit, Richter’s Engine Disassembly and Assembly Trainer gives students real-world practice with physical components and automotive repair tools, making the learning stick.

4. Meeting Industry Standards Through Tool Mastery

Industry certifications like ASE (Automotive Service Excellence) demand that technicians master specific tools to prove competency. For instance:

| ASE Certification Area | Critical Tools Required | Training Focus |

|---|---|---|

| Brakes (A5) | Brake piston compressors, spring removers | Brake system diagnostics and repair |

| Electrical/Electronics (A6) | Digital multimeters, circuit testers | Fault diagnosis in vehicle electrical systems |

Richter's Automotive Electrical System Trainers are built with these standards in mind, helping students build confidence using the same automotive repair tools pros rely on for ASE certification.

5. Real Pain Points Training Programs Face—and How Richter Helps

Pain Point #1: High cost of quality tools limits training scope.

Solution: Richter offers affordable, comprehensive tool kits and trainers, allowing programs to equip more students without breaking budgets.

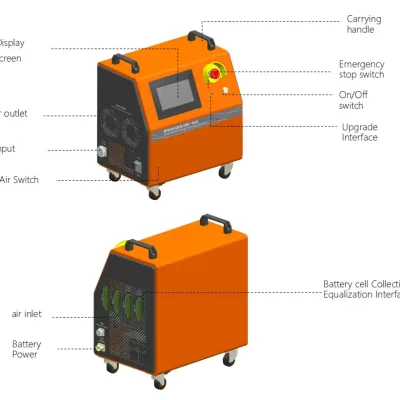

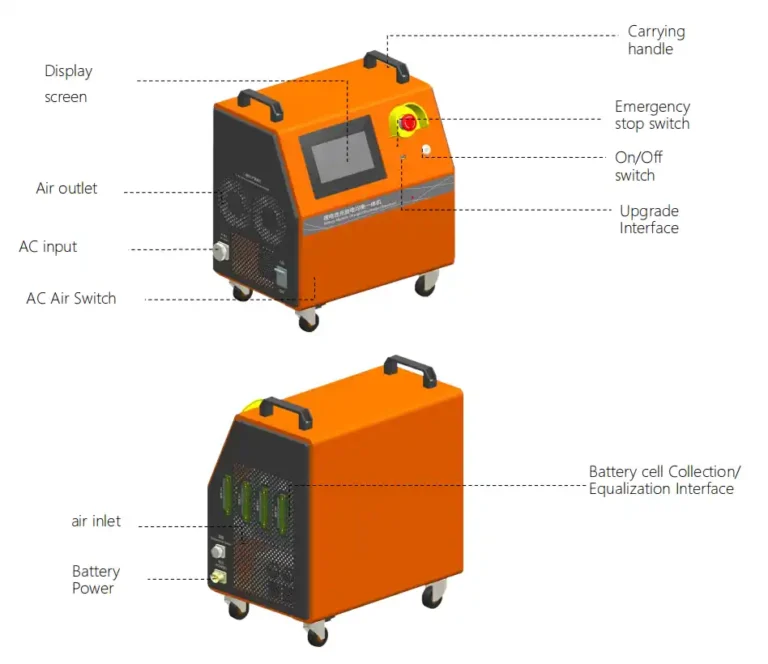

Pain Point #2: Tools not matching vehicle tech updates cause outdated skills.

Solution: Richter stays ahead by updating training equipment for electric vehicles, hybrid systems, and advanced diagnostics. Check out the Electric Vehicle Power Chassis Fault Diagnosis System that covers cutting-edge tech for future-ready skills.

Pain Point #3: Managing tool organization and accessibility slows workflow.

Solution: Richter’s automotive repair tools car sets come with storage solutions designed to keep tools organized and portable for busy shops and classrooms.

6. Commercial Value: Why Investing in Quality Training Tools Pays Off

Good training gear isn’t just a cost—it’s an investment. Schools that equip students with real tools and comprehensive trainers see better certification pass rates, higher job placement, and more satisfied employers. Employers know graduates trained on Richter equipment hit the ground running.

The ROI is real: fewer remediations, stronger reputation, and easier accreditation. That’s why Richter partners with institutions globally to deliver full-system trainers, tool kits, and software simulations—creating learning ecosystems that prepare students for real-world challenges.

Wrap-Up: Get Your Hands on the Best with Richter

If you want your students or trainees to gain solid, hands-on automotive repair skills, start with the right tools. From core hand tools to specialized trainers for brakes, engines, and electric systems, having gear that matches your curriculum is key. Richter delivers that, plus the expert support to keep your program ahead of the curve.

Check out our full range of automotive training tools and trainers today, and give your learners the hands-on experience they deserve.