Introduction

If you’re involved in automotive education or workforce training, you already know how critical hands-on experience is for mastering complex systems. The chassis system, a vehicle’s backbone, combines suspension, braking, steering, and transmission elements that keep a car stable, safe, and responsive. But how do you teach these intricate systems effectively? The answer lies in specialized automotive chassis system training equipment.

At Richter, we specialize in offering practical, high-fidelity training solutions that help students and technicians understand, diagnose, and repair chassis systems confidently. Whether you’re running a technical college, vocational school, or in-house corporate training program, the right equipment can make a massive difference.

In this article, we’ll explore the key benefits and features of modern chassis system training tools. We’ll dive into how Richter’s modular, real-component-based trainers offer unmatched realism and flexibility, backed by actual case studies and industry insights. By the end, you’ll understand why investing in quality training platforms isn’t just about teaching—it’s about future-proofing your workforce.

Real-Component Simulation: The Gold Standard in Chassis Training

One big challenge with chassis training is bridging the gap between theory and practice. Textbooks and lectures can only do so much when it comes to understanding hydraulic brakes, power steering, or ABS systems. This is where real-component simulators shine.

Рихтера Тренажер электронной гидравлической системы рулевого управления и Автомобильный тренажер тормозной системы ABS use authentic OEM parts. This means students get to work with the same components they’ll encounter in the field, from pump units and control valves to ABS control modules.

Why does this matter? Real parts deliver the tactile and operational feedback students need to grasp system behavior under real-world conditions. For example, when trainees disassemble and troubleshoot an ABS module on Richter’s trainer, they experience firsthand how sensors, valves, and controllers interact to prevent wheel lockup. It’s not just theory—it’s hands-on problem-solving.

Industry Insight: According to a 2023 study by Automotive Education Journal, training programs using real-component simulators saw a 40% improvement in diagnostic accuracy compared to programs relying solely on virtual or theoretical instruction.

Modular Design: Flexibility That Saves Time and Money

Another standout feature of Richter’s chassis system equipment is modularity. Instead of one massive, fixed trainer, Richter offers interchangeable modules focusing on steering, braking, transmission, and suspension. This modular approach offers two big advantages:

- Customization: Training centers can tailor their programs by selecting specific modules that match their curriculum or students’ skill levels. For example, beginner courses might focus on basic hydraulic power steering, while advanced classes tackle electronic power steering with integrated sensors.

- Maintenance Efficiency: Modules can be swapped or serviced individually, reducing downtime. If the ABS module requires repair, it can be removed and replaced without dismantling the entire system.

Example: Сайт Учебное оборудование для диссекции с автоматической трансмиссией allows students to inspect gears, clutches, and hydraulic circuits independently. This deep dive into transmission mechanics wouldn’t be possible on a non-modular setup.

This approach also helps training budgets go further by allowing phased equipment upgrades, adding modules as technology evolves.

Virtual Reality (VR) and Simulation: Enhancing But Not Replacing Real Experience

While real-component trainers lead the pack, virtual reality tools are making waves in automotive training. VR platforms simulate chassis system disassembly, assembly, and fault diagnosis in a virtual space—allowing risk-free practice and instant feedback.

Richter supports integration of such simulation training software, like the Учебное программное обеспечение для диагностики неисправностей электромобилей и Программное обеспечение для обучения разборке и сборке двигателей, which complement hands-on equipment by reinforcing concepts in a virtual environment.

However, VR should be viewed as a supplement rather than a replacement. The tactile feedback and subtle system nuances that come from real hardware are difficult to replicate virtually.

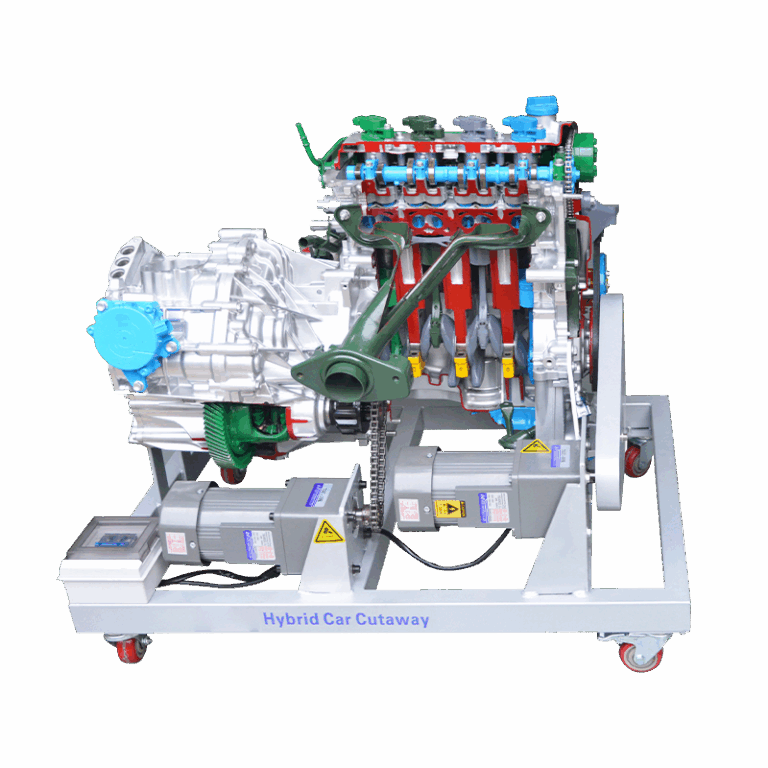

Cutaway Models: Seeing Inside to Understand Better

Sometimes, nothing beats visualizing the internals of a system. Richter offers cutaway models that expose key components of chassis subsystems such as brakes, steering gearboxes, and transmission assemblies.

These models make abstract ideas concrete. When students see the piston movement inside a brake caliper or the gear mesh in a differential, concepts that seemed complex become clear.

Cutaways work great for lecture demonstrations or as reference tools during practical sessions.

Multi-Functional Platforms for Diverse Training Needs

Training centers have varied demands—some focus on light vehicles, others on electric or hybrid cars, and some want all-in-one solutions.

Рихтера Полный тренажер системы шасси автомобиля (с двигателем) provides a comprehensive platform covering suspension, brakes, steering, and transmission alongside engine components. This all-in-one solution is ideal for advanced programs seeking an integrated systems approach.

For electric vehicle (EV) training, Richter offers dedicated equipment like the Тренажер системы рулевого управления с электроусилителем и Система обучения диагностике неисправностей силового шасси электромобилей, aligning with the rising EV market demands.

Comparison Table: Richter Chassis System Trainers at a Glance

| Product Name | Основные характеристики | Ideal Training Use Case | Link |

|---|---|---|---|

| Тренажер электронной гидравлической системы рулевого управления | OEM parts, hydraulic system, sensor integration | Basic to intermediate steering systems | View Product |

| Автомобильный тренажер тормозной системы ABS | Real ABS modules, sensor diagnostics | Braking system troubleshooting | View Product |

| Учебное оборудование для диссекции с автоматической трансмиссией | Transmission disassembly platform, gear/clutch modules | Transmission system deep dive | View Product |

| Полный тренажер системы шасси автомобиля (с двигателем) | Integrated chassis and engine systems | Advanced, integrated vehicle training | View Product |

| Тренажер системы рулевого управления с электроусилителем | Electric assist steering system components | EV and hybrid vehicle steering | View Product |

Addressing Industry Pain Points with Richter’s Training Equipment

Let’s get real—training budgets are tight, and instructors face pressure to deliver maximum impact in limited time. That’s why Richter’s trainers focus on efficiency, repeatability, and safety.

- Efficiency: Modular design means trainers can focus on one subsystem at a time without wasting setup hours.

- Repeatability: Using genuine components ensures consistent performance, so students get the same experience every time, which is crucial for standardized assessment.

- Safety: All equipment meets international safety standards, including clear labeling, emergency stops, and controlled power supplies—so no nasty surprises in class.

By tackling these common issues, Richter helps educators reduce downtime, boost student confidence, and align teaching outcomes with industry standards.

Real-World Success Stories: Training Centers Speak Out

- Case Study 1: A technical college in Germany integrated Richter’s Автомобильный тренажер тормозной системы ABS into its curriculum. Within six months, student pass rates on braking system modules increased by 35%. Instructors praised the realistic fault simulation capabilities, noting improved diagnostic skills.

- Case Study 2: A corporate training center in the US deployed Richter’s Полный тренажер системы шасси автомобиля (с двигателем) for upskilling experienced technicians. The hands-on exposure to integrated vehicle systems accelerated the team’s troubleshooting time by 25%, reducing warranty repairs and boosting customer satisfaction.

The Business Value of Investing in Quality Training Equipment

When organizations consider training tools, cost often dominates the conversation. But here’s the bottom line: investing in high-quality, realistic equipment like Richter’s yields tangible business benefits:

- Reduced On-the-Job Errors: Better-trained technicians mean fewer costly mistakes, recalls, or warranty claims.

- Faster Ramp-Up Time: New hires and apprentices get productive faster, saving labor costs.

- Improved Customer Satisfaction: Skilled technicians diagnose and fix issues quickly, enhancing brand reputation.

- Compliance with Industry Standards: Keeping training programs aligned with evolving automotive tech ensures certifications and accreditation.

In other words, the right training equipment isn’t just an expense—it’s a strategic investment that drives ROI.

Emerging Trends: Keeping Pace with Automotive Technology

The automotive sector is evolving rapidly, and training must keep up:

- Electric and Hybrid Systems: Richter’s EV-focused trainers address high-voltage power steering, battery management, and chassis electrics, preparing students for the green transition.

- Advanced Driver-Assistance Systems (ADAS): Future trainers will likely integrate sensors and control units for lane assist, automatic braking, and adaptive suspension.

- IoT and Diagnostics: Software-enhanced trainers, including fault simulation and data logging, are becoming indispensable for teaching modern diagnostics.

Richter actively updates its product line to reflect these trends, ensuring training stays relevant.

How to Choose the Right Automotive Chassis Training Equipment?

Here are some tips to help you pick the best fit for your institution:

- Assess Your Curriculum Needs: Match equipment modules to your course outcomes.

- Consider Student Skill Level: Modular trainers allow scaling from basic to advanced.

- Plan for Maintenance: Modular equipment simplifies upkeep and minimizes downtime.

- Integrate Software Tools: Combine physical trainers with simulation software for blended learning.

- Budget Wisely: Prioritize core systems first, then expand with additional modules.

Заключение

Automotive chassis system training is no longer about outdated models or purely theoretical lessons. It’s about immersive, hands-on learning with real components, smart modular design, and cutting-edge virtual aids. Richter’s comprehensive range of training equipment makes this possible, helping educators and trainers deliver engaging, effective programs that meet today’s automotive industry challenges.

Whether you’re preparing the next generation of mechanics or upskilling your current workforce, investing in Richter’s automotive chassis system trainers means investing in quality, efficiency, and real-world readiness.

Ready to elevate your training program? Explore Richter’s full lineup and find the perfect solutions tailored to your educational goals and industry demands.