Why Hybrid Vehicle Training Tools Matter More Than Ever

The automotive industry is shifting gears. Hybrid vehicles are no longer a niche; they’re becoming mainstream. That means schools training the next generation of technicians can’t rely solely on old-school tools or theory. Instead, they need training gear that matches the tech complexity these new rides bring.

This is where specialized hybrid vehicle diagnostics and repair training equipment come into play. These tools give students real-world, hands-on experience diagnosing and fixing hybrid systems—from battery management to electric motors and high-voltage safety.

At Richter, we’ve been tracking these industry trends closely. Our lineup of hybrid vehicle trainers and diagnostic tools helps schools bridge the gap between classroom learning and real-world service bays.

Оглавление

The Essential Gear Every Hybrid Technician Needs

Let’s break down the must-have tools in hybrid vehicle diagnostics and repair training:

| Tool Type | Purpose | Richter Product Example & Link |

|---|---|---|

| Insulated Hand Tools | Protect students when working with high-voltage components | 318 Электрический автомобильный (изолированный) гибридный набор инструментов |

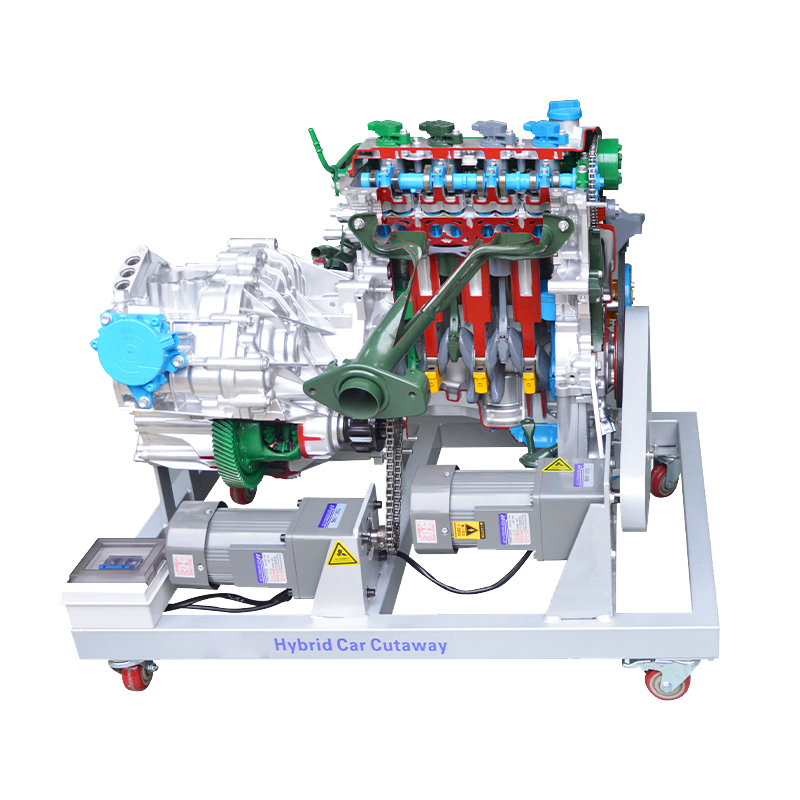

| Hybrid Powertrain Trainers | Teach power flow, energy recovery, and motor diagnostics | Тренажеры для гибридных энергосистем |

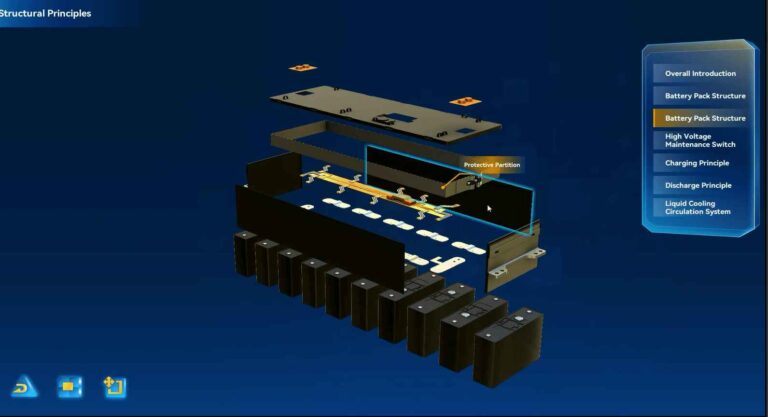

| Battery Assembly & Testing | Train battery pack maintenance and troubleshooting | Система обучения технологии сборки и тестирования силовых батарей |

| Diagnostic Software & Simulators | Enable virtual fault simulation and system analysis | Учебное программное обеспечение для диагностики неисправностей электромобилей |

| Electric Motor Disassembly Trainers | Hands-on experience with motor repair and rebuild | Тренажеры по разборке приводного двигателя электромобиля |

These aren’t your typical mechanic’s wrenches and sockets. Hybrid training tools include high-voltage insulation, system-level simulators, and software-enabled diagnostics. They let students understand how electric energy flows through the drivetrain and how to troubleshoot common faults.

Real-Life Impact: How Hands-On Hybrid Vehicle Diagnostics And Repair Training to Job-Ready Skills

Instructors who’ve adopted hybrid trainers from Richter report a noticeable difference in student engagement and skill acquisition. Instead of merely memorizing battery specs or electric motor theory, students can visualize energy flow and interact with actual system components. This practical exposure builds what we call “tech intuition”—the gut feeling that guides diagnostics when things don’t look textbook-perfect.

For example, a community college in California using Richter’s Hybrid Power System Engine Transmission Dissection Trainer observed that students’ diagnostic accuracy improved by over 25% in just one semester. The ability to physically disassemble and test components under supervised conditions gave learners confidence and cut down troubleshooting time in simulated faults.

Overcoming Industry Pain Points With Hybrid Vehicle Diagnostics And Repair Training Equipment

We all know the industry faces some serious challenges, especially around hybrid vehicles:

- Safety Risks: Working on high-voltage systems is inherently risky without the right insulated tools and training.

- Rapid Tech Changes: New battery chemistries, power electronics, and control systems come out every few years, making older equipment obsolete.

- Budget Constraints: Schools want cutting-edge equipment but need solutions that don’t break the bank.

- Theory-Practice Gap: Classroom lessons alone can’t prepare students for real-world diagnostic complexity.

Richter tackles these pain points head-on. Our 318 Электрический автомобильный (изолированный) гибридный набор инструментов ensures safe hands-on work with high-voltage components. Meanwhile, our modular trainers and software simulators keep schools up to date without constantly replacing entire toolkits.

The Role of Diagnostic Software & Simulation in Hybrid Training

One thing that’s changing the game is the integration of software simulators with physical training. Virtual fault injection, system behavior visualization, and real-time feedback make learning faster and safer.

Рихтера Учебное программное обеспечение для диагностики неисправностей электромобилей lets instructors create custom fault scenarios that students diagnose in a virtual environment before working on actual hardware. This approach sharpens troubleshooting skills and reduces costly mistakes.

Curriculum Integration and Certification: Preparing Students for the Market

It’s not just about owning the equipment—schools need to weave hybrid training tools into a comprehensive curriculum. That includes safety protocols, diagnostic best practices, and certification prep.

Schools partnering with Richter can tap into our training courses and resources, like our Training Courses page, which align with industry standards and certifications. This ensures students graduate with skills employers want and recognized credentials.

Industry Demand: The Growing Need for Hybrid-Savvy Technicians

Hybrid and electric vehicle sales are soaring worldwide. According to recent forecasts, by 2030, hybrids could make up over 40% of new car sales in key markets. This shift fuels a skyrocketing demand for technicians who understand hybrid powertrains inside out.

Technicians trained with Richter tools stand out to employers because they’ve mastered:

- High-voltage system diagnostics

- Battery health assessment and management

- Power electronics troubleshooting

- Electric motor repair

In short, Richter-trained technicians don’t just survive in the evolving automotive landscape—they thrive.

Future Trends: What’s Next for Hybrid Vehicle Diagnostics And Repair Training?

Looking ahead, expect hybrid training to become more integrated with AI-driven diagnostics and VR/AR-based immersive learning. However, physical trainers will remain essential—they give tactile experience no simulation can fully replace.

Richter is already exploring next-gen tools that combine hardware with smart software to provide adaptive, personalized training paths. The goal? Help schools future-proof their programs and prepare students for whatever comes next in automotive tech.

Final Thoughts: Why Richter Should Be Your Partner in Hybrid Training

Choosing the right hybrid vehicle diagnostics and repair training equipment isn’t just a purchase—it’s a strategic investment in your students’ futures. Richter offers reliable, industry-aligned tools designed with safety, versatility, and affordability in mind.

If you’re ready to empower your students with the best hands-on experience and prepare them for a career in tomorrow’s automotive industry, check out Рихтер’s full hybrid training lineup at.