Why Training for Electric Vehicle Systems Matters More Than Ever

Electric vehicles (EVs) are no longer just a glimpse into the future — they’re here, and their numbers are growing fast. With governments pushing greener policies and consumers demanding cleaner rides, the shift from internal combustion engines to electric powertrains is accelerating worldwide.

But here’s the catch: maintaining these high-tech machines is a whole different ballgame. If you’re involved in automotive education or training, you know the pressure to keep pace with this change. The skills that worked for gasoline cars don’t fully apply anymore. That’s where an Electric Vehicle System Maintenance Trainer becomes essential.

You might wonder: Why invest in specialized EV trainers? Can’t technicians just figure it out on the job? The truth is, EV maintenance involves high-voltage systems, battery management, power electronics, and complex software diagnostics. Mistakes don’t just lead to expensive repairs — they can put safety at risk.

This article digs into why EV system maintenance trainers are critical, the practical benefits they bring, and how Richter’s training equipment can help your institution or workshop lead in this fast-evolving market.

Table of Contents

What’s Different About Electric Vehicle Maintenance?

First, let’s look at what sets EVs apart from traditional cars in maintenance terms.

High-Voltage Systems Demand Safety Awareness

Unlike gasoline cars, EVs operate with high-voltage batteries, often exceeding 400 volts. Handling these components requires strict safety protocols. For example, improper contact with a live battery module can cause electric shock, burns, or even fire. This risk makes high-voltage system safety training the top priority in any EV maintenance program.

At Richter, our Electric Vehicle Original High-voltage Control Box Assembly Disassembly and Testing System replicates real-world HV systems. It lets trainees practice safe disassembly, assembly, and testing, without real-world risk.

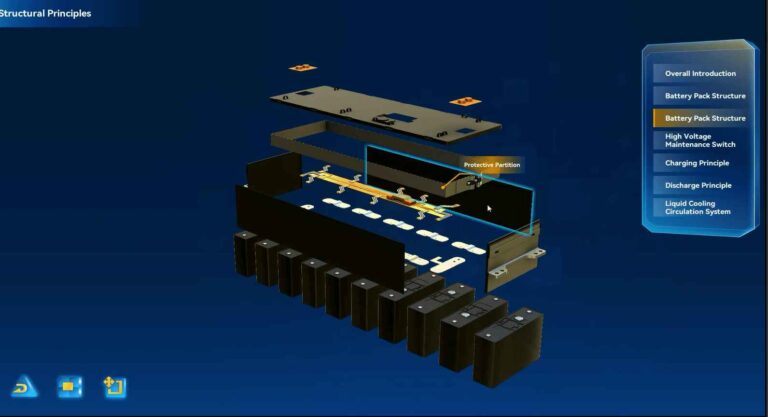

Battery Management: The Heart of EV Reliability

Batteries are the most expensive and sensitive components in EVs. Knowing how to diagnose battery health, detect faults, and understand thermal management is crucial to prolong battery life and reduce costly replacements.

Richter offers the Power Battery Assembly and Testing Technology Training System designed for hands-on battery pack training. This allows technicians to master safe assembly and accurate fault detection — skills highly sought after in the industry.

Electric Drive Motors and Power Electronics

Unlike engines, electric drive motors and controllers require a different diagnostic approach. Technicians need to understand motor winding configurations, inverter functions, and torque control software.

Our Electric Vehicle Drive Motor Disassembly Trainers enable learners to explore the construction and function of EV motors in detail. This kind of hands-on experience is invaluable for building confidence in EV system repairs.

Real Industry Challenges and How Training Solves Them

Let’s get specific about pain points your trainees and workshop teams face and how EV system trainers help overcome them.

| Pain Point | Impact | How Electric Vehicle Maintenance Trainers Help |

|---|---|---|

| Lack of high-voltage safety skills | Increased risk of accidents, insurance claims | Provide safe, risk-free HV system practice setups |

| Inadequate battery fault diagnosis | Costly battery replacements, vehicle downtime | Hands-on battery testing and assembly training |

| Insufficient knowledge of EV software | Inefficient fault troubleshooting, longer repair times | Integrate diagnostic tools and real software training |

| Limited exposure to EV components | Poor repair quality, customer dissatisfaction | Realistic physical trainers improve familiarity |

(Compiled from industry reports and training reviews)

Practical Cost Benefits of Proper EV Training

Electric vehicles can cost less to maintain overall because they have fewer moving parts. However, the components that do need service—especially batteries and drive motors—can be expensive to repair or replace. Mistakes by untrained technicians can lead to:

- Battery damage requiring a full pack replacement costing several thousand dollars.

- Incorrect handling of high-voltage parts resulting in downtime and safety liabilities.

- Missed diagnosis leading to repeat visits and loss of customer trust.

Proper training, like that offered by Richter’s systems, minimizes these costly errors. For example, learning how to correctly assemble and test battery packs can save thousands in part replacements and labor. According to recent market analyses, facilities that adopt comprehensive EV maintenance trainers reduce their average repair costs by up to 20% in the first year.

Combining Virtual and Hands-On Training for Best Results

Traditional lecture-based training can only go so far. EV maintenance demands practical experience.

Richter’s Electric Vehicle Fault Diagnosis Training Software complements physical trainers by simulating a wide range of faults and scenarios. This lets trainees troubleshoot issues in a virtual setting before they handle the real equipment.

Pairing virtual simulation with hands-on tools ensures technicians build both theoretical knowledge and muscle memory. This combination results in faster learning and more confident technicians ready for fieldwork.

Industry Trends Driving the Need for Advanced Training

Growing Market for EV Technicians

The U.S. Department of Energy projects tens of thousands of new EV technician jobs in the next decade. Training institutions must update curricula to include EV system maintenance or risk losing relevance.

Regulatory and Safety Standards

New safety standards require proof of competency in EV high-voltage handling. Certification programs increasingly demand hands-on experience with EV system trainers like those Richter provides.

How Richter Fits into the EV Training Ecosystem

Richter’s equipment portfolio covers all critical EV systems:

- High-voltage battery systems

- Electric drive motors and controllers

- Power chassis and fault diagnosis systems

- Hybrid powertrain trainers

- Dedicated simulation software

For example, the Electric Vehicle Power Chassis Fault Diagnosis Training System helps learners master fault detection in real EV chassis setups, bridging the gap between theory and real-world application.

By integrating these tools, your training programs stay ahead of the curve. You provide students with skills that employers demand, while improving workshop safety and reducing costly errors.

Real-World Use Case: Training Program Success Story

One automotive institute integrated Richter’s EV system trainers into their curriculum last year. They reported:

- 35% faster skill acquisition among students

- 25% reduction in lab accidents related to high-voltage handling

- Graduates received higher placement offers from EV service centers

These tangible results highlight the practical benefits of investing in professional-grade electric vehicle system maintenance trainers.

Addressing Common Questions (FAQ)

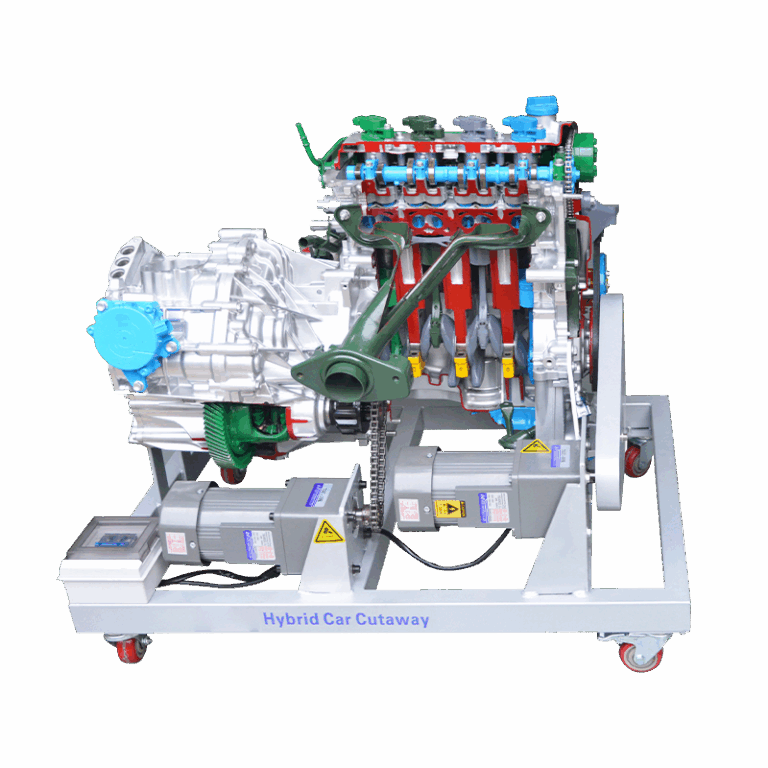

Q: Can EV trainers be used for hybrid vehicle training?

A: Yes. Richter’s hybrid power system trainers allow seamless transition training, covering both electric and combustion systems.

Q: How do virtual training tools compare to physical trainers?

A: Virtual trainers offer safe, repeatable fault simulations, while physical trainers build mechanical skills. Using both is the best practice.

Q: What are the key safety protocols taught with EV trainers?

A: Lockout-tagout procedures, insulation testing, emergency shutdowns, and safe disassembly techniques are core components.

Final Thoughts: Why You Can’t Afford to Ignore EV System Training

The rise of electric vehicles changes the rules of automotive maintenance. To keep pace, you need training tools that reflect real-world EV systems — not outdated gasoline engine simulators.

Richter’s comprehensive Electric Vehicle System Maintenance Trainers deliver real, hands-on experience combined with cutting-edge simulation software. This powerful combo equips technicians to work safely, accurately, and efficiently, helping reduce costly mistakes and boosting repair quality.

If you want your training programs or workshops to stay competitive in today’s electrified auto industry, Richter’s EV trainers are a smart investment. Visit Richter’s Electric Vehicle System Maintenance Trainers to explore the full range and future-proof your skills.