Richter – Automotive education Training Courses

Electric Vehicles After-sales Maintenance Skills Training Program

Global EV Technician Training Program

Build Core EV CompetenciesIn-depth analysis of electric vehicle architecture and working principles. Covering high-voltage systems, battery management and electric drive technology

Master Diagnostic & Repair SkillsStrengthen fault diagnosis and maintenance operation training. Use OEM standard tools and process flow

Meet Worldwide Market DemandsCustomized content based on regional market characteristics. Continuously update courses to match technology evolution

GreenShift – Page-Building Gutenberg Blocks

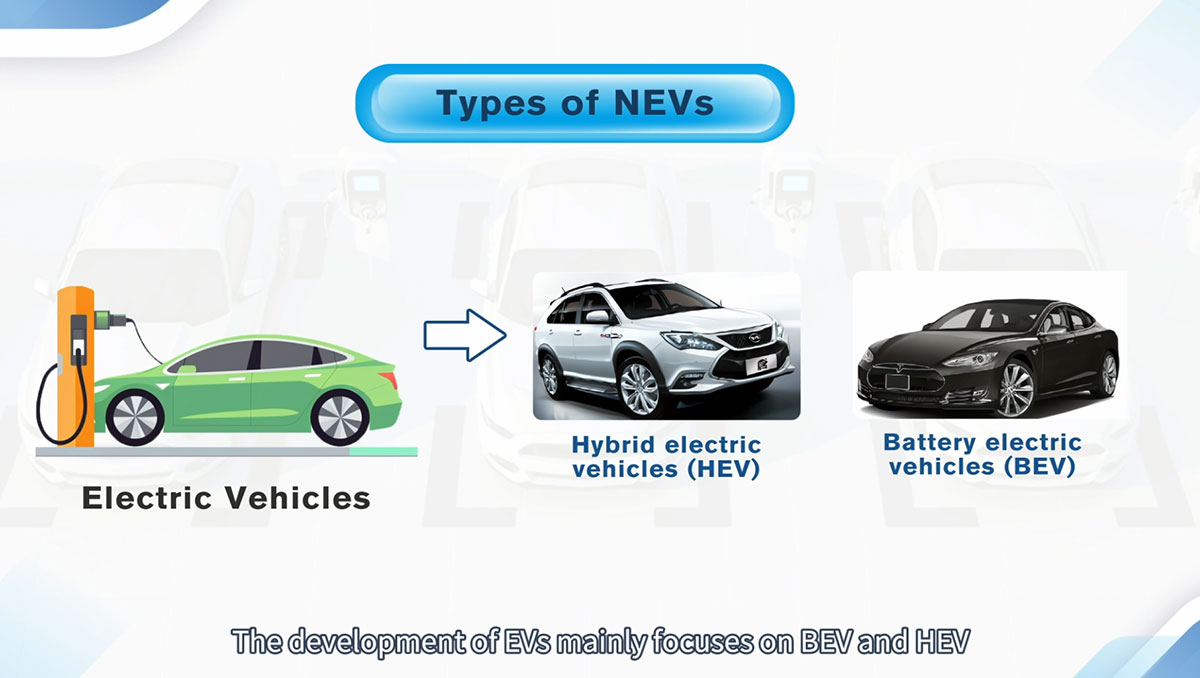

1. Basic knowledge of Electric Vehicles

Definition and classification of Electric Vehicles (pure electric vehicles, extended-range electric vehicles, hybrid electric vehicles, fuel cell electric vehicles, etc.).

Electric Vehicles technology principles and development trends.

2. Structure and principle of Electric Vehicles

Battery system structure and principles (types, working principles and performance characteristics of lithium-ion batteries, nickel-metal hydride batteries, etc.; battery management systems, battery thermal management technologies).

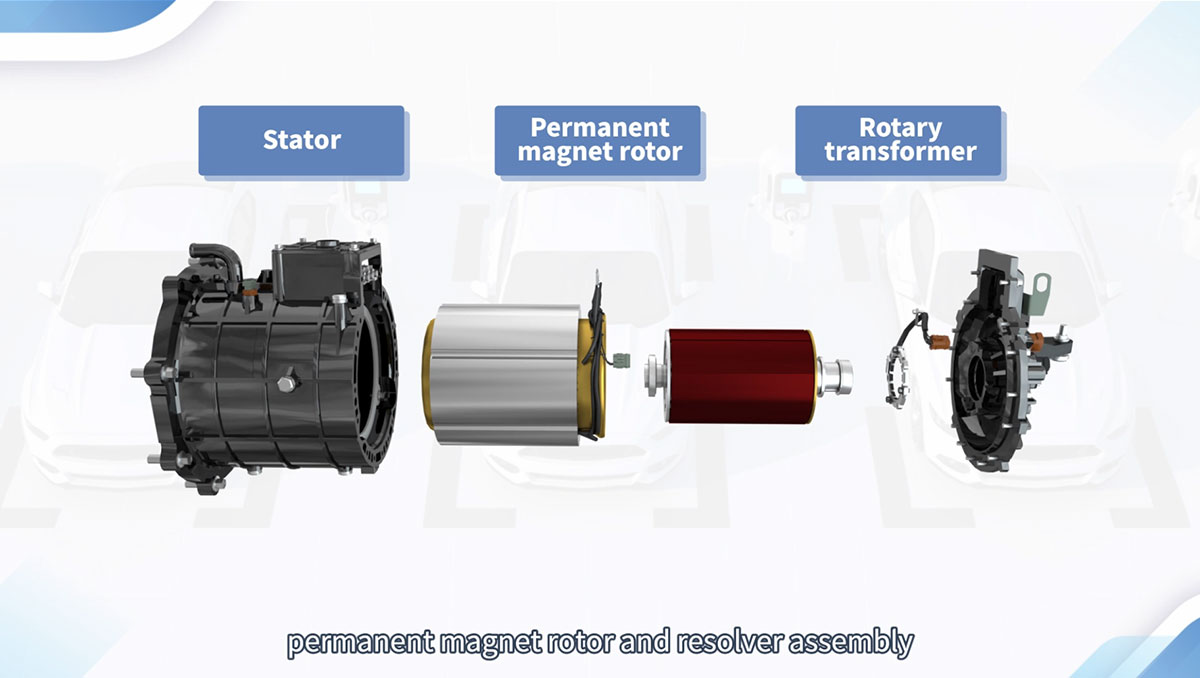

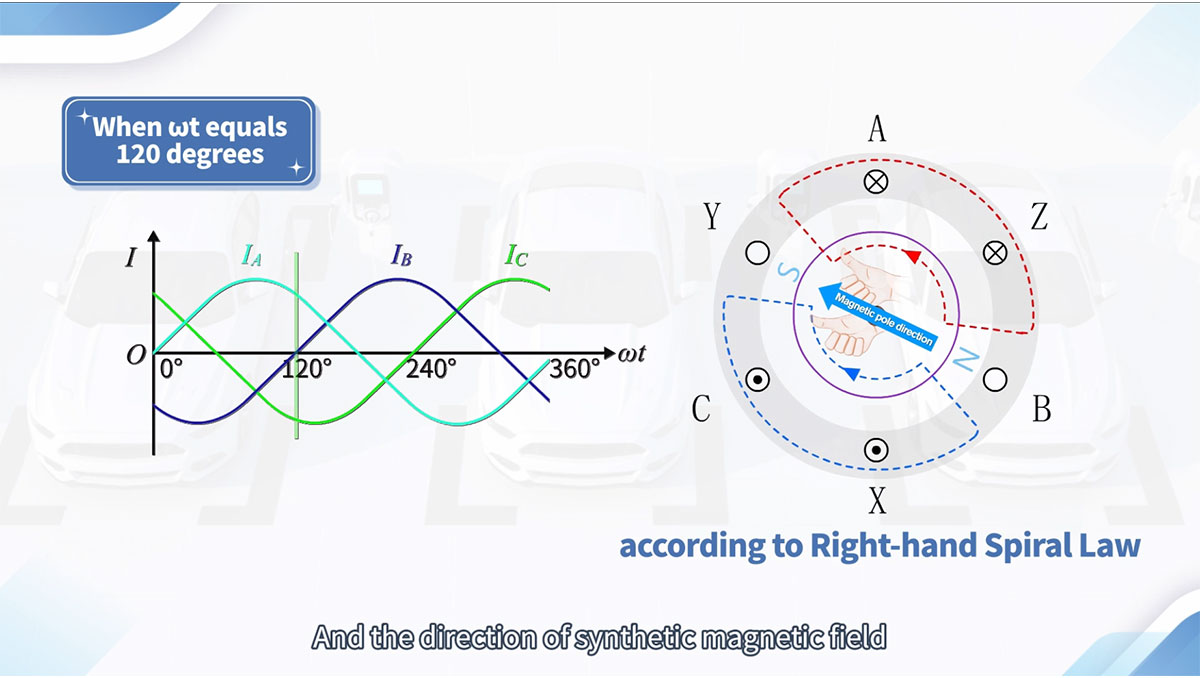

Motor and control system structure and principle (types, working principles and performance characteristics of permanent magnet synchronous motors, AC asynchronous motors, etc.; motor control system functions, composition and working principles).

Vehicle CAN communication network topology and electrical network topology.

3. Introduction to maintenance tools and equipment

Usage instructions and precautions for commonly used maintenance tools and equipment.

Use of diagnostic tools, host computer software, etc., and reading of fault codes, data stream analysis.

Use of diagnostic tools, host computer software, etc., and reading of fault codes, data stream analysis.

4. Common fault diagnosis and troubleshooting methods

Power battery fault diagnosis and troubleshooting (internal resistance measurement, balanced charging, temperature and voltage acquisition faults, etc.).

Motor and electronic control system fault diagnosis and troubleshooting (temperature sensor measurement, component withstand voltage test, abnormal noise and insulation fault diagnosis, etc.).

DC/DC converter and OBC vehicle charging system troubleshooting method.

Introduction to knowledge related to electrical fault troubleshooting of the whole vehicle.

5. Basic knowledge of Electric Vehicles

Daily maintenance and care requirements for Electric Vehicles

Guidelines for parts replacement and maintenance

Guidelines for parts replacement and maintenance

6. Basic knowledge of Electric Vehicles

Analysis of typical fault cases

Maintenance experience exchange and sharing

Maintenance experience exchange and sharing

Course details form

| Training level | Training content | Training time | Training methods |

|---|---|---|---|

| Level 1: Electric Vehicles knowledge and high voltage safety operation | 1. Basic knowledge and development trends of Electric Vehicles | 1 day | Theoretical explanation + interactive Q&A |

| 2. High voltage safety operation specifications and accident prevention | 1 day | Theoretical explanation + practical demonstration | |

| 3. MSD repair switch insertion and removal and safety operation | 0.5 days | Practical exercises + safety guidance | |

| 4. Electric Vehicles power-off and high-voltage components understanding | 0.5 days | Practical exercises + Component Display | |

| Level 2: Electric Vehicles structural principles and key component disassembly and assembly | 1. Overall structure and working principle of Electric Vehicles | 1 day | Theoretical explanation + graphic illustration |

| 2. Power battery structure and disassembly and assembly practice | 2 days | Theoretical explanation + practical exercises | |

| 3. Motor and electronic control system structure and disassembly | 2 days | Theoretical explanation + practical exercises | |

| 4. Principle of DC/DC converter and OBC vehicle charging system | 1 day | Theoretical explanation + equipment display | |

| Level 3: Electric Vehicles maintenance and performance testing | 1. Daily maintenance and care specifications for Electric Vehicles | 1 day | Theoretical explanation + practical demonstration |

| 2. Use diagnostic equipment for fault diagnosis and data analysis | 2 days | Practical exercises + data interpretation | |

| 3. Diagnostic and repair solutions for specific brands such as Tesla | 1 day | Theoretical explanation + practical case study | |

| 4. CAN/LIN communication network troubleshooting | 1 day | Practical exercises + network topology analysis | |

| Level 4: Electric Vehicles battery, motor and electronic control fault diagnosis | 1. Power battery in-depth fault diagnosis and troubleshooting | 2 days | Practical exercises + case analysis |

| 2. Advanced fault diagnosis of motor and electronic control system | 2 days | Practical exercises + circuit diagram analysis | |

| 3. DC/DC converter and OBC troubleshooting and repair | 1 day | Practical exercises + equipment use guidance | |

| 4. Comprehensive diagnosis of vehicle electrical system faults | 1 day | Comprehensive drill + actual case analysis |

Empowering Global EV Talent: Skills Development for Industry Growth

This comprehensive training program enhances the technical expertise and service capabilities of EV maintenance professionals worldwide. By equipping technicians with standardized knowledge and hands-on skills, we support the growing demand for qualified personnel across global markets, driving sustainable development of the electric vehicle industry.

Training Methods

Training Evaluation and Assessment

Training cycle and arrangement

Empowering Global EV Talent: Skills Development for Industry Growth

This comprehensive training program enhances the technical expertise and service capabilities of EV maintenance professionals worldwide. By equipping technicians with standardized knowledge and hands-on skills, we support the growing demand for qualified personnel across global markets, driving sustainable development of the electric vehicle industry.

Can I participate in this training without any basic knowledge? What are the prerequisites?

What brands of electric vehicles will the training cover?

How to ensure safety in high-voltage operation training?

Will real vehicles or simulators be used for training?

Are the diagnostic tools used for teaching the same as those in 4S stores?

Can I consult if I encounter technical problems after graduation?